AUSTIN 1800

How the concept of XC90001 became the Austin 1800 (ADO 17)

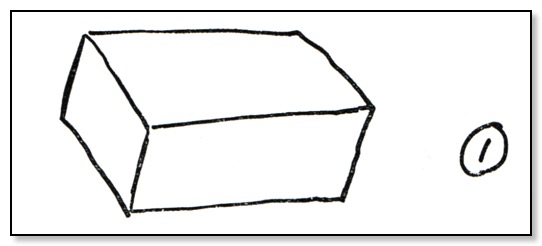

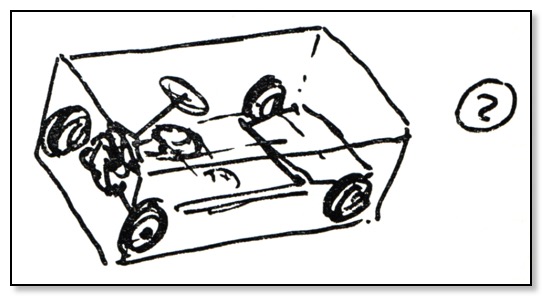

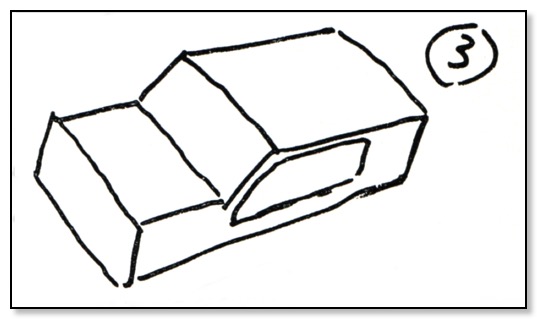

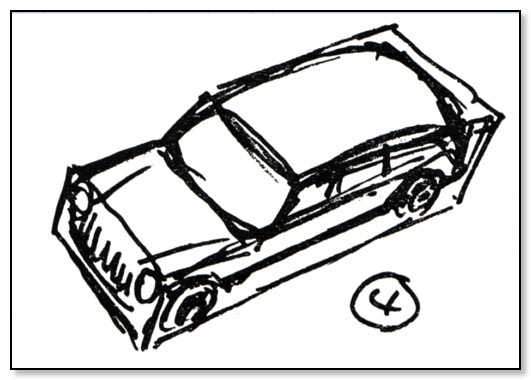

These sketches below were made by Mr. Issigonis to show the various concept stages.

Design stages

Before the design of a car is started one has to decide on its overall dimensions. A box is therefore drawn into which the finished car will just fit.

Into this box is then put all the mechanical design which positions the engine, the wheels, the seats and so on.

A piece is then cut away from this box, forming the position of the windscreen, defining the height of the bonnet, and apertures are cut into the sides to represent door through which the passengers can enter the car.

This forms the basis upon which Pinifarina completes the three-dimensional aspect of the car.

At was in late 1958 that Mr Alec Issigonis, Technical Director of BMC turned his attention to what at the time was called XC9001, which became the Austin 1800.

The new engineering concept created by the Mini, and later by the 1100, led the BMC management to believe that it would be beneficial to introduce one more car, a larger one in this case, designed around this basic philosophy. This new car would therefore be the third in the line of front-wheel-drive transverse-engined cars that Issigonis had designed.

Long before pencil is put to paper on a new model a great deal of thought is taken when ideas begin to crystallise. These are put on paper in the form of a small quarter-scale drawing, so that one can be sure that by looking at the design as a whole, the balance of the complete car is to, one's satisfaction.

At this stage these early drawings are passed over, in this case to Mr. C D Kingham, who is entrusted with the problem of working out the details and all the practical work that is required, to ensure that some of the speculative features of the design have a practical coherence before a physical prototype is actually built.

From the original XC9001 concept a revised version was produced by Pinafarina as shown below. This now looked more like the ADO16, but having a very prominent front grille.

This shows the next stage, with its cleaner front end, doors, roof line and rear end treatment now have the lines of the ADO17

Design Cell B

One of the design 'cells' at Longbridge responsible for car design, B Group is not, as often believed, responsible for cars using the B Series engine, the units of around one and a half litres employed in the A55-A60 and Morris Oxford range. 'it just happened that way,' Mr. C. D. Kingham, Superintendent of the Group, told BMC World, 'We came into being towards the end of 1959, after the Mini had been introduced, and, as we came after A Group we took the next letter!' B Group took up the ADO17 project, which had been shelved during the evolution of the Mini, and some thought was given to a different design before the final decision was taken to adhere to the transverse engine front-wheel drive concept which was then on the road with the Minis, and well advanced with the 1100s. At the same time it was decided that the use of the sub-frames, a feature common to the other two, would not be followed in the new car.

In this way the basic characteristics of the 1800 were decided and the task facing B Group (which in the field of engineering is regarded as a design 'cell') could be seen more clearly. Within the cell there has to be complete trust and co-operation at every stage, and between every man, whether they were putting their ideas down on paper or whether they were translating those ideas into parts of the new car. Mr. Kingham emphasized that the cell system, operating with a very small staff and dedicated to the single project, greatly expedited the work on ADO 17 in the initial design stage. Thereafter the design facilities of the other engineering departments were brought into full play. Soon BMC. Body Experimental, under Mr. R. (Dick) Gallimore, came right into the picture and it was the close contact with this department which made it possible to get ahead with the job so quickly. At this stage Body Experimental worked from a quarter-size overall drawing showing only the key mounting points on the body supplemented by full-sized undimensional layouts of the structural build up. 'They took over this complex,' said Mr. Kingham,' and from it they not only produced every member, panel and bracket but they related it the final assembly.' The final body design provides a structure of incredible rigidity; indeed by measurement it has about twice the stiffness of other modern saloon cars. This is a factor of immediate importance in the solidity of the car on the road, and needless to say, long term, the life of the car must obviously be lengthened.

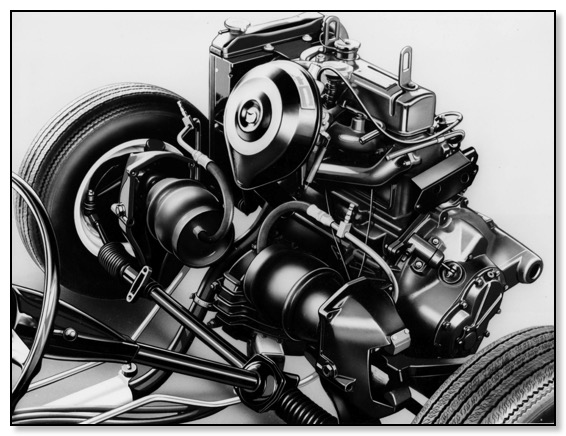

Engine - Transmission Development

While work on the new body was going ahead Mr. W V Appleby, Chief Engineer, Engine and Transmission Division, was working on the design for the engine and transmission unit. It is only when Bill Appleby designers begin to work out details of the power unit can thy be sure that the space under the bonnet is sufficient, and so becomes a practical reality.

To enable this power unit development to be translated into production achievement the skill of the tool room under the Superintendent, Mr. A. Lavender, has been meticulously applied. Huge transfer machines of original design have been completely dismantled and re-erected in modified form. To fit in with the styling of the vehicle the disposition of the engine, transmission and final drive had to be varied from that of the Minis and 1100s in order to achieve good ground clearance coupled with a low bonnet line. Once the layout had been decided in outline, the task of detailed design was passed over to the main Design Office.

Styling Work

After the initial design, which is in a two dimension form, it is necessary to check by doing a three dimensional clay model that the external appearance of the body is acceptable. This stage is entrusted to Pininfarina through the channels of our Styling Studio at Longbridge, under the charge of Mr. R. Burzi.

Farina has to work very closely to the initial profile of the car so far as physical dimensions are concerned, and when studies have been thoroughly discussed, it is time to build a full-size mock-up of the car. This is a hollow steel shell representing the car in its final three dimensional form. This phase of the work is tedious and exhausting because the model itself has to be built in Turin and as a result entails a lot of travelling and very close communication between ourselves and Farina. The mock-up is eventually shipped to Longbridge for inspection and criticism by BMC management and it may be that even at this stage small detail modifications have to be carried out before final approval is given to proceed with the tooling of the external skin surfaces.

Running Prototype

We are now in a position to start work on the building of a complete, running prototype car. Issigonis was alway very apprehensive at this stage because, with so much at stake, the first run in a prototype, can very often prove very disappointing. He therefore insisted that he would always be the first person to drive the car, so on the 18 May 1962 it took to the road.

In the case of the ADO17, I must admit that for once in a while my impressions of the first run down the road were favourable. This doesn't mean that the development that normally lies ahead on a prototype is finished; in fact, no matter how impressed one is on the first run there still remains a great deal of work to be done before the design can be approved for production. The development of the prototype is a long and tedious job because it entails a great deal of testing, not only of the car but also of its components, which include suspension rig tests and long endurance runs of the power unit on the test bed.

One of the main differences with the Mini/1100 was the decision not to use sub-frames. This meant that the body would have to be made stronger to absorb all the loads via the suspension from the road. The final body design actually provided a structure of incredible rigidity; indeed by measurement it had about twice the stiffness of other modern saloon cars of that period. This is a factor of immediate importance in the solidity of the car on the road, and needless to say, long term, the life of the car must obviously be lengthened.

As this work proceeds Issi would be visiting the various departments, sometimes on a daily bases to see if important decisions needed to be made quickly relating to certain parts of the programme which were not progressing satisfactorily. The progress of this stage was very important to Issi because for the first time, he could appreciate or apprehend whether his initial design was sound or not. Also at this critical stage the decision has to be made whether the proceed with it as planned, or making substantial revisions to the general concept.

Tooling Begins

It is necessary at this stage to order the body tooling, because of the lead time. On going work continues on these two prototypes' detail refinement, until such time as most of the major components of the car are available off tools. Several more cars are built using panels etc from production designed tooling, this checks that the machine-made parts fulfil their function as well as the hand-made parts did on the hand-built prototypes.

The cost of building further test models for general check and test purposes in this way is very much reduced, and it is, therefore, possible to make a statistical analysis of the general progress of the vehicle. It must be remembered that a modern car is such a complex piece of machinery that it is obviously not possible to be sure that two cars identical in design behave identically in practice.

Whilst the engineering work was progressing, parallel to this departments allied to production were coming on board. Body production planning within BMC. had now gone beyond Longbridge. Indeed when ADO17 went into production, with the final body assembly being done in West Works, two Fisher & Ludlow factories were also playing their parts. The main factory at Castle Bromwich was contributing panel sets and sub-assemblies while Lianelly, already responsible for over 20,000 doors for the 1100 every week, were now be supplying doors for the new model.

Few body changes were found necessary with the prototype but a great deal of vital work was done to make it a working production proposition. In the Car Assembly Planning Department under Mr. Harold Cross measures were been taken to prepare for the day when the car went into production. It was necessary to incorporate all the features of the ultimate Trentham and CAB Assembly lines into this pilot line with the object of proving the jig and fixture design before production commenced.

In the case of the Austin 1800, around twenty cars were built in a pre-production form on a pilot assembly under the direction of Mr W H Davis, Deputy Managing Director in charge of Production. This process can often highlight problems in assembly of the car, so further detail design modifications can be put in place to make assembly easier for those on the track.

As the number of cars available for testing by the Road Proving Department was on the low side, it was necessary that this work would be going on 24 hours a day. Outside suppliers could do some of their testing on rigs, but sometimes they would need to borrow a car to do development, so this was usually done at night using their own facilities. All the important proving had to be done, including the bedding and testing of the brakes, cooling, endurance and pave testing, which involving weeks of night testing and running. But eventually ADO17 became more than a project number on a designer's notebook, it had now been turned into the Austin 1800.

Press Release Launch

Introducing the AD017 to the British and Continental Press was a formidable task, one of combining the maximum impact with the maximum secrecy, for all new cars especially those from BMC are always such big news that details of them are avidly sought.

The next stage is the final full-scale production, but it is very important to have opinions of many people, both skilled and unskilled, to assess the merits of the car. So consultations between Mr. Alec Issigonis, Technical Director of BMC, and the Publicity Department which resulted in a recommendation being made to the Chairman, Mr. G. W. Harriman, that the venue for the ADO17 Press Launch should be in the Highlands of Scotland. Mr. Brian Turner was tasked to organise the pre-production cars to be tested by a large section of the international motoring Press.

One of the original Press Cars

These cars were prepared by a small department called Press Garage, which was under the umbrella of South Experimental. The operation was carried out in a remote part of Scotland, where journalists, who must naturally be taken into our confidence, had therefore been invited to test the car. Such was the number of persons attending from around the world, that it took nearly two months before the operation was completed. The general consensus of opinion at the time was one of overwhelming enthusiasm for the new model. This appraisal from a highly critical and sophisticated group of experts gave hope that this new car had a great future.

Remoteness

The Highlands were chosen for three main reasons. The first was that they offered the necessary security and remoteness from prying eyes, and the second that the Highland roads with their gradients and sharp bends would bring out to the full the car's high qualities and general road ability. Thirdly it was felt that since the visiting journalists would be coming from every European and Scandinavian country they would welcome an opportunity to see some of the beauties of the British Isles.

Accordingly Mr. A L H. (Tony) Dawson of Publicity was given the task of organising the parties, Mr. Issigonis handing him a map torn from his own diary on which certain roads had been outlined in ink as suggested routes for the parties. Even in March it was not easy to find a suitable hotel in the seclusion of the Highlands which could offer the facilities required to accommodate the visiting Pressmen in circumstances which could offer reasonable hope of guarding the secrets of the new car.

Eventually, with the co-operation of the Scottish Tourist Board, one was found. A quick decision had to be made since the hotel had newly become open to general bookings for the new season, and, so no time was lost, although there were still a few 'outside' visitors who must have wondered just what they had stumbled across.

Firm Base

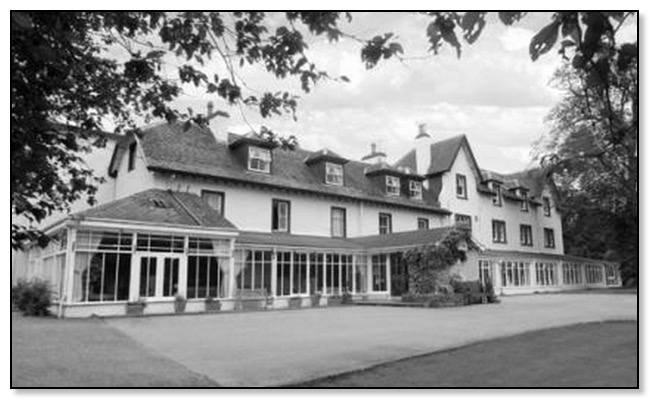

Hotel in Garve

The hotel was at Garve, near Inverness, and, a firm base having been established, it was possible to go on with the general planning and then into the complexities of detail. Tony Dawson spent an entire week-end in London, for instance, with a representative of the firm handling the air travel arrangements in planning flight bookings required to bring Pressmen from as far away as Finland, Portugal, and Austria. Parties from 14 countries had to be arranged with flights in each direction, travel to and from Scotland (which included British journalists) having been taken care of by a block charter with British United Airways, using Daleross Airport, Inverness.

Airport Welcome

Overseas distributors had to be fitted into the picture so that their representation could come with the journalists from their own countries, and escorts had to be arranged front BMC. Publicity to be on hand at London Airport to greet the visitors on arrival. The visitors were brought to Birmingham, where accommodation had been arranged for an overnight stay, and next day they had their first glimpse of the Austin 1800 in an impressive Exhibition Hall display at Longbridge.

Up in Scotland there was a mass of planning to be done. On arrival at the airport there the visitors were met by coach and taken to Garve, with special permission sought, and won, to use roads not normally open to the public. Overflow accommodation using another hotel and caravans had to be arranged.

Routes had to be planned which would not only give the visitors chance to savour all the features of the new car's performance but which would also not expose it too much to the gaze of the curious. All the time it had to be remembered that foreign drivers might not find it easy to drive on the 'wrong side' of the road on single track Highland roads.

The visiting Pressmen had the opportunity to drive the cars during two full days out in the Highlands and, to make sure that the cars were kept in peak condition-and they were being put through their paces by a succession of drivers on some of the most difficult roads in the British Isles-a servicing team was set up in Scotland.

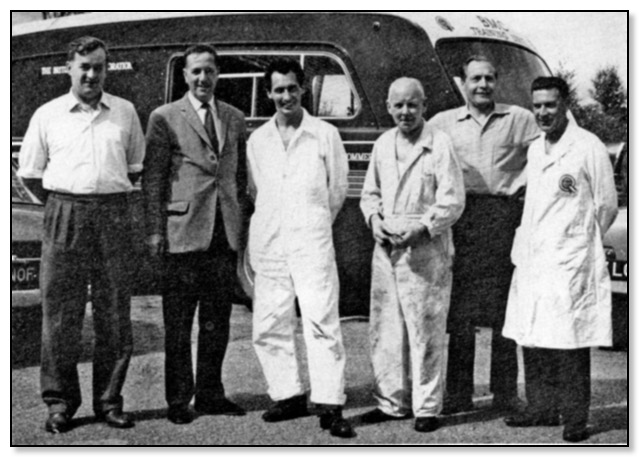

Servicing Team

Barry Wood - Gil Jones - Pat Layton - George Coats - ? - ?

Arrangements for servicing were made by Mr. Gil Jones, Chief Experimental Engineer, BMC, who was in charge of the team at the outset until he was relieved by Mr. Bernard Johnson, Chassis Experimental Engineer at Longbridge. Mr. George Coates, foreman of the demonstration car garage at Longbridge, travelled north to take charge of the workshop and with him were Pat Layton (engine fitter), Les Griffiths (body, interior work and trim) and Arthur Irish (sheet-metal worker) who replaced Barry Wood all of them drawn from Longbridge's main experimental department.

The servicing side was completed by one of the mobile service schools from BMC. Service School, Cowley, which was taken up to Scotland by Bernard Williams and Harold Collins not only with spare parts but to make the vehicle's normal equipment available. From BMC. Service, too, were Les Godfrey and Chris Robson, making up a party which made certain that AD017 was well and truly launched.

The Highland operation fell within the orbit of Messrs. Macrae and Dick, Austin and Nuffield Distributors in North West Scotland and not only did BMC. representatives receive considerable help and co-operation from Mr. W. Hamilton, there Managing Director, and his staff, but some of the parties had the pleasure of being received by the Provost of Inverness at the Town House-and the Provost is Mr. W. J. MacKay,

The car is the creation of one man's brilliant mind, Mr. Alec Issigonis, Technical Director of BMC, who has watched over every detail in bringing his concept to fruition helped by a small but talented design staff in which his right hand man was Mr. Charles Griffin, Chief Engineer Passenger Cars, BMC.

The first prototype of the AD017 took the road on 18 May 1962 and at the time the car was first seen by the motoring correspondents of European countries it had been 'on the go' in B group of BMC Designs Projects at Longbridge for two and a half years.

Final approval

Styling, incidentally, was by Sergio Pininfarina and his Chief Engineer with the co-operation at Longbridge of Mr. Issigonis, Mr. Griffin, and Mr. Dick Burzi, Chief Stylist, BMC Final approval of the styling came from Mr. G W Harriman, Chairman and Managing Director, In the Design Office the project came under the direction of Mr. W V Appleby, BMC's Chief Power Units designer, work on the new transmission being the particular responsibility of Mr. Harry Gardner, and on the engine of Mr. Eric Bareham.

Away from Longbridge too, Tractor and Transmissions Branch were responsible for front and rear suspension assemblies including hubs and steering assemblies. BMC's resources were being brought more and more to bear on the ADO17 with the ‘cell’ always there to initiate and progress the work. O when the work on designing the new power unit had been brought still further forward, it could be taken in hand by the Engineering Division’s Power Unit Development. under Mr Don Hawley.

So the two main parts of the new car were envisaged, designed and produced and at the same time other parts of it were being created too, until the prototype had been made and that prototype lived for exactly two years and a day.

MKI

Date launched October 1964 to May 1968

Total produced 6,781

Engine

1798cc 80 bhp at 5,000rpm Max torque 100lbs/ft at 2,100rpm

Main measurements

Length 13ft 8.2ins Width 5ft 7ins Height 4ft 7.5ins

Wheelbase 8ft 10ins Track front 4ft 8ins rear 4ft 7.5ins

Price at launch £828

Engine-Transmission and Front Suspension

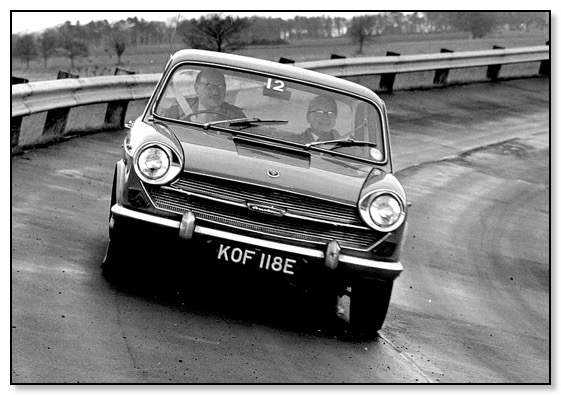

Press Driving at MIRA

Austin 1800 MKII

Date when launched Dec 1968 Discontinued in 1972

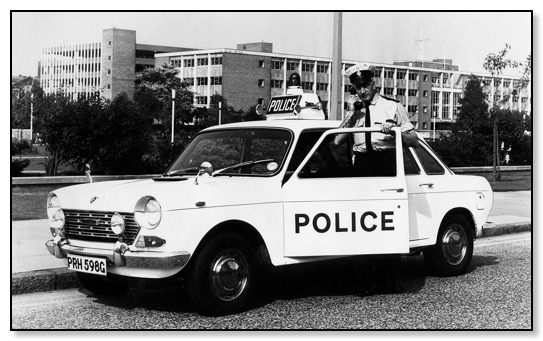

Police Car MKII

Body Assembly in West Works

Coming off the line CAB 1 in the 1960s