The War Years 1914-18

Suddenly, motoring or what used to be called pleasure motoring, receded into the background. The Austin Motor Company found itself, like many other firms, confronted with new problems, which included not merely those usually associated with the motor industry, but problems new to the engineering world generally because of the shear volume of production needed. No precedents were available, they had a well equipped motor works with a work force of about 2,800, and were in the act of calmly preparing for the November Motor Show with their new models. But all that was about to change as war contracts became the order of the day. There was an immediate and insistent demand for cars, lorries, aeroplanes, aero engines, guns, shells and munitions generally on a colossal scale.

The scale of deliveries of munitions, vehicles, planes etc is staggering. (See end of article)

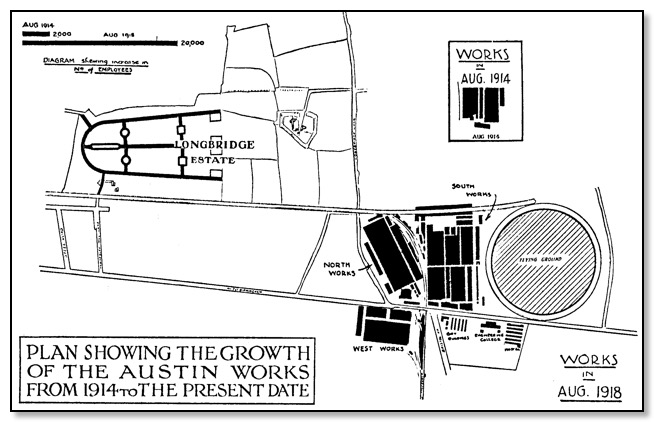

Doubling the original size of the works was, however, only the commencement of the growth. The need for armaments grew by leaps and bounds, and the response of Austin grew with it. So it was necessary at the end of 1914 to enlarge South Works to build a new shop to make the 18lb shells along with the 9.2in shells. Starting in April 1916 this big shell shop in two months had reached an output of 2,000 shell per week. This output was slowly increase over the following months so that by March 1917 the output had reached 5,000 shell per week. More new buildings comprising of a forge, stamp shop, two more machine shops (No 2 & No 3) along with a bond room and various erecting shops.

North Works 1914-8

The following year a large building was constructed and called Block No 9. Because the land was sloping, a large amount of earth had to be removed, in fact 150,000 cubic yards. Further building Block No 6 was finished in 1917 which comprised aeroplane erecting shops, dope and sewing room. Further on the South side was a aero engine machining and assemble shop along with testing facilities.

1914-8 North Works, Thomas Seabright Superintendent

(Seated 4th from Left second row)

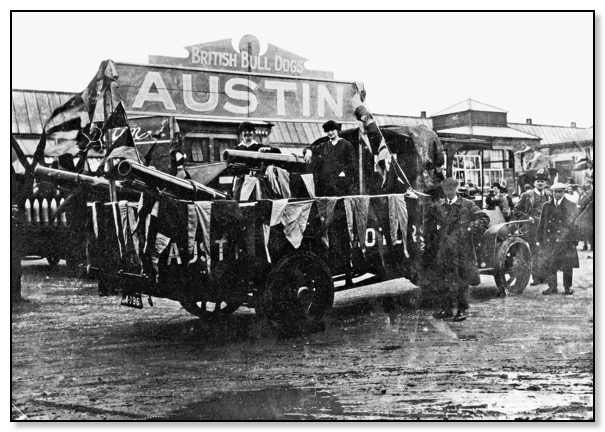

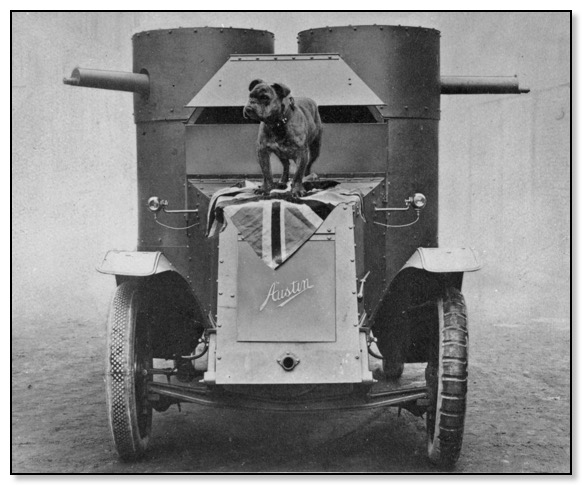

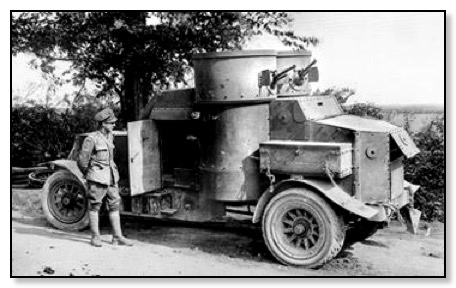

ARMOURED CARS

Austin decided that with the wealth of experience in building motor vehicles, they could design an armoured car with some unique features. The name given to this vehicle was ‘Dreadnought’ It was capable of traveling at 50 MPH on a good road. With a complement of six men, the vehicle had a couple of machine guns and searchlights. It’s main role was to get men to the front line as quick as possible, and to return for more. You could say that it was a miniature fort with it’s two shrapnel-proof / bullet-proof turrets which housed the machine guns. It had the unique ability to be driven and steered from either end. The driver had a pair of Periscopes front and back to see where he was going and should the outside glass get broken a new one could be easily replaced.

Armoured Cars at 'K' Gate

Notice the different tyre tread patterns

Austin Armoured Car

Note the Larger Rear Wheels on this Version

Austin Armoured Car Polish Army 1920

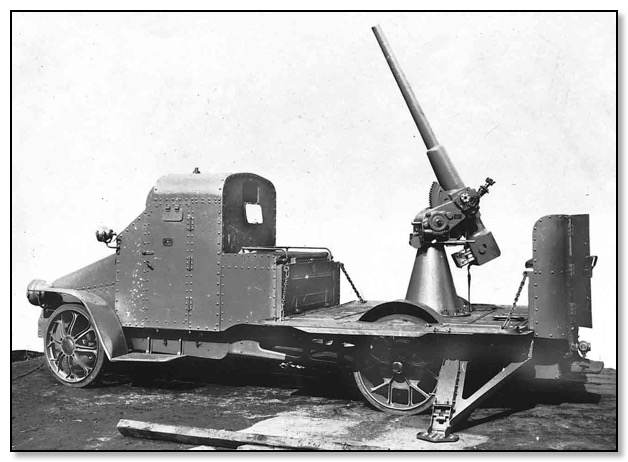

Austin-57-AA-Gun

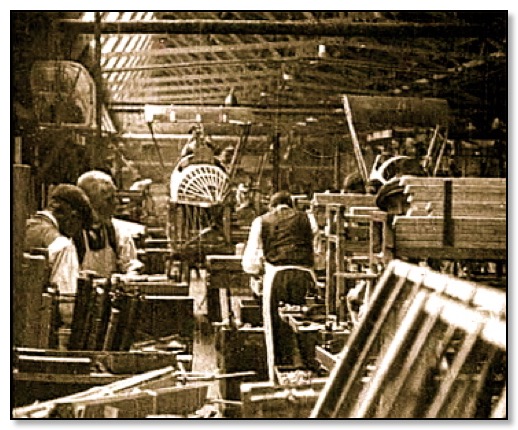

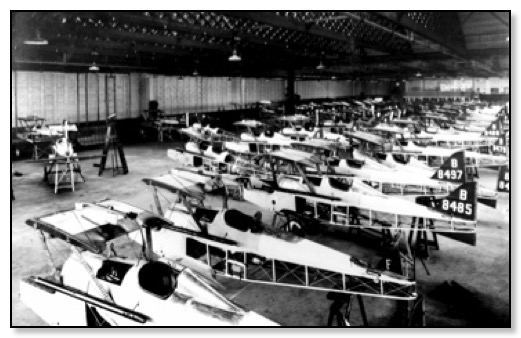

Aeroplanes were produced, the first government contract was given for the RE 7 plane with production commencing September 1915. Fifty two planes were delivered, a revised version called RE 8 was developed and a order for 300 placed. In 1918 a order was placed for 350 SE 5 planes, the order was revised several times, ending with a total of 1550. At the start of this contract the delivery schedule was one plane per day (24hrs). With the larger numbers required, production rose steadily to an average of 30 per week. From Monday 3 June to Saturday in six days they turned out sixty three planes. Aeroplanes construction in those days was very much like aero modeling. The body of a plane contained thousands of separate and accurately made pieces of wood which were then assembled together. One of the grey arts was the ‘doping’ of the canvas, because if not done correctly the canvas skin would be too tight and so was libel to tare, if loose it was not very aerodynamic and would also tare. The Austin dope-room was regarded as the best in the country because it was fully ventilated along with a controlled temperature. At this time all this experimental work and production need skilled men who could manufacture the aircraft, At the time Longbridge had about 130 aircraft carpenters and about 200 riggers and fitters.

Attached to South Works was a hill called Cofton Hill this was levelled off giving an area of seventy three acres. The airfield was laid out like spokes of a wheel, with runways pointing in different directions connected by a perimeter road. This was a brilliant design as planes were able to take off what ever the wind direction

Aeroplane Production in the Wood Shop

SE 5a Biplane Production South Works

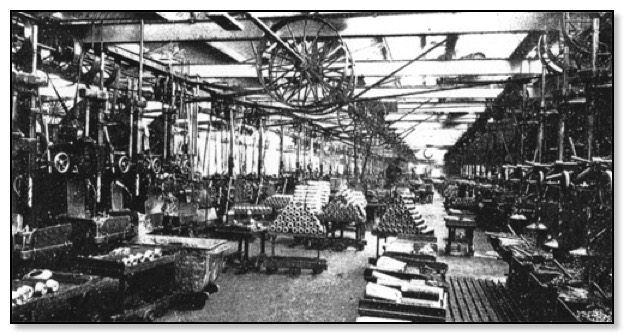

.July 1916 work on North Works commenced for a huge shop measuring 850ft x 270ft together with a long building to house the new forge, running along side with a machine shop. By Christmas the buildings had been completed and by March 1917 the forge was producing its first blanks. Production steadily rose with the forge producing 20,000 blanks per week with the machine shop at 15,000 shells per week. There were two immense bays devoted to the machining of 4.5in howitzer guns.

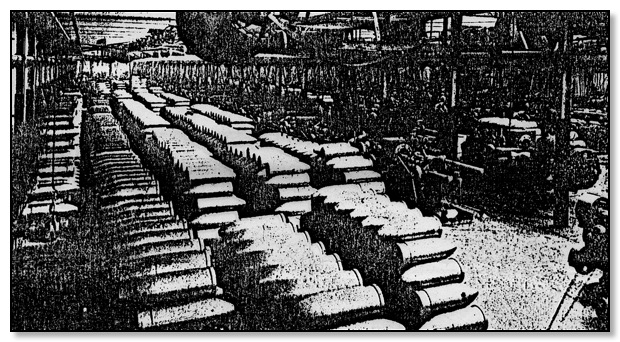

18lb SHELLS

The total production of 18 lb shells during the war period was amounted to six and a half million, to produce his quantity you needed 80,000 tons of steel bar. It is difficult to envisaged what 6.5 million shells look like. Somebody worked out that if you put them end to end they would stretch from Lands End to John o Groat’s and half way back a distance of 867 miles. At the height of the production, 1,200 tons of steel bar was used every week, which meant two train loads each day. Production of the shells was so prolific that they were running out of storage space. In one week they dispatched no less than 150,000 shells and a daily rate for a nine and a half hours was running at 13,000.

Machine Shop 18 Pounders

In December 1916 the demand for munitions was still rising, so work commenced on the land opposite the Bristol Road which became known as West Works. It was an exceptionally hard winter, so building work was particularly difficult, but by working continually day and night with flares used to help at night, the building was ready for fitting out in June 1917. Large foundation were made to accommodate the heavy machinery that was to be installed including presses which could exert a pressure of 750 tons. A large machine shop measuring 660ft x 330ft was soon machining 100,000. 18lb shells per week.

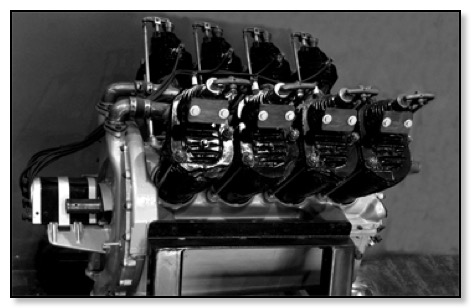

Aero Engines

USAF Museum

USAF Museum

RAF 1a V8 Aero Engine

Such was the demand for aero engines that British manufactures were having difficulty in supplying, so other firms were given contracts to supply. At the time there were two engines that the Austin was awarded contracts for. One was for the RAF 1A which was a air cooled V8 and produced about 90 HP, this was a very successful engine and the Longbridge plant made about 2,400. The second engine called the Arab had been designed by the Sunbeam Company, this was also a V8 which had a power output of just over 200 HP. Austin was awarded an order but from the outset there was a major design fault so in the end only about 100 were actually built.

Aero Engine Production South works

Ambulances Lorries etc

Making vehicles for war situations is not the same as in peace time, and initially some components would fail under these tough conditions. But a lot of knowledge was gained on the stress and strains that components were subjected to. A specially strengthened 20hp chassis was used for a variety of jobs. This was the backbone for the various bodies that were mounted including Ambulances, X-Ray apparatus, Field kitchens and General stores.

Delivered by the Austin Motor Co to HM Government and Allied Governments from October 1914 to the end of contracts in 1918.

Shells:

13 : 25,000

15 : 100,000

8.0in : 980,000

210mm : 60,000

9.2in shells 350,000

18-pounders 6,500,000

Guns 650

Lorries 2,000

Ambulances 148

Aeroplanes 2,000

Trace Troughs 34

Electric Motors 25

Armoured Cars 480

Night Tracers 506,399

Pumping Equipment 40

Shrapnel Heads 47,768

Percussion Tubes 682,808

Burster Containers 167,791

Working Trailer Wagons 3,405

Electric Generating Sets 4,762

Touring Cars, Light Vans etc. 750

Switchboards and Resistances 4,423

Aeroplane Engines (various kinds) 2,500

Along with large quantities of spare parts for lorries, aeroplanes etc.

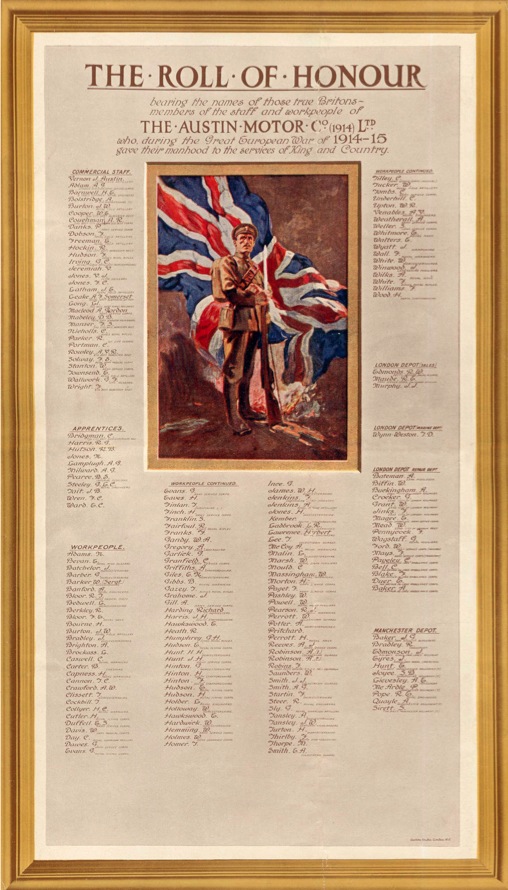

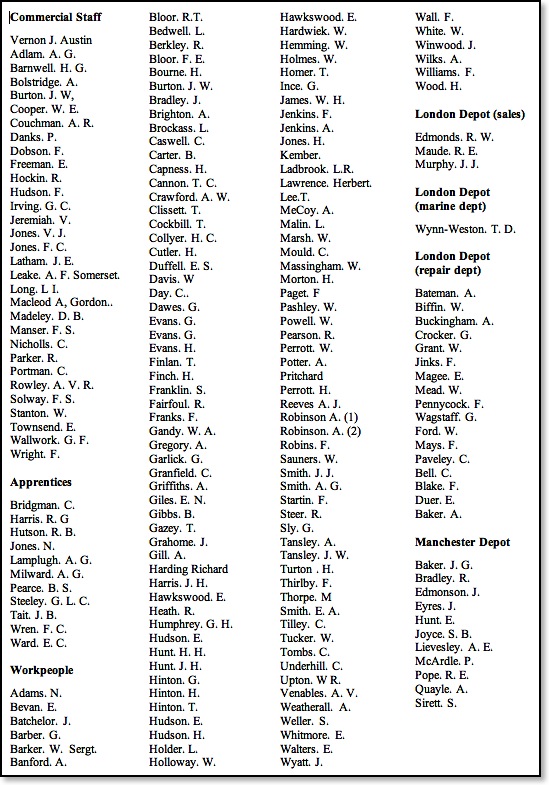

Roll of Honour Supplied by Mr A Eves