RAF prepares to increase production for WW II

Most of the arrangements for the expansion of the aircraft industry to meet the abnormal needs of the Government's plans for air rearmament have now been made, and the work involved in increasing the' productive, capacity of the industry is in hand. The project is being realized under two heads. In one case the new factories, which were, originally known as “shadow” factories and are now officially described as, Government factories are being set up, and in the other the existing aircraft factories are being extended largely at Government expense. By the two methods the requirements of the RAF. during the next two years will be easily supplied. Further than this the foundations will have been laid for still greater expansion of the Service if this should be found necessary and for providing a large output of military aircraft and their equipment at short notice if war should break out.

Government factories already in operation. include six which are concerned with the manufacture of engine parts and the assembly of those parts into complete engines, one which is producing complete aircraft, one which is manufacturing airscrew, and two which are engaged in producing carburettors. In addition, an establishment which is not in the strict sense a Government factory has been set up to produce magnesium alloys for the use of the manufacturers. These will be supplemented within a short time by the output of Bristol Blenheim twin-engined bombers from the big factory at Liverpool. At a later stage Lord Nuffield's factory at Castle Bromwich will be turning out Supermarine Spitires, and no doubt the engines for its products will come from the new factory at Crewe which will undertake the manufacture of Rolls'-Royce Merlin 1,060 hp engines.

In Motor Car – Factories

It is already well known that the six factories associated in the supplementary production of Bristol Mercury engines are managed by prominent motor-car manufacturers. At the Austin works at Longbridge, near Birmingham, crankshafts, reduction gear, oil supply systems, and controls for airscrews are made; at the Rover works, near Birmingham, the products are connecting rods,. pistons, valves, spring, and other gear; cylinders are being made at the Standard works at Coventry; the Daimler factory at Coventry is responsible for crankcases, oil pumps, priming systems, and certain other parts; and the Humber works at Coventry has undertaken the manufacture of various drives, of the blowers, the oil pumps, and of the crankcase rear covers. Under the scheme the parts are assembled and the complete engines are tested by the Austin Motor Company and the Bristol Aeroplane Company.

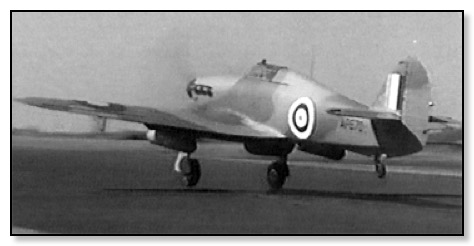

At the Austin works complete aircraft of the Fairey Battle type are now being turned out regularly. Tne corresponding airframe factory for the manufacture, of Blenheims at Liverpool has already begun work in the production of parts but has not yet reached the stage at which the whole airframe is assembled on a regular output plan. When this stage is reached during the next few months it is believed that the rate of output- will be very high. Meanwhile steps have been taken to provide the extra carburettors which the engines will need and the variable-pitch airscrews they are intended to drive. The carburettor factory, managed by the firm of Hobson, is established at Oldham. The airscrew factory, additional to the de Havilland works at Stag Lane and managed by that firm, is near Bolton. The works for the production of alloys, arranged on a slightly different footing from the others, is in the hands of the Magnesium Elektron Company.-

The whole of this structure may be regarded as primarily a war potential, employed in the present expansion so than experience may be gained, and liable to be contracted at the end of the expansion period and held in readiness for further full employment if war should occur. A parallel scheme, allied to the regular aircraft industry, is also in process of realization. A number of the firms, which are acknowledged as contractors to the Air Ministry, have been authorized to proceed with the extension of their works. Some of these schemes mean big. expansions. That of the Bristol Aeroplane Company will cost nearly £1,100,000. There are others of lesser magnitude, but most of the cost in all these cases will be borne by the Government.

The. aircraft firms will thus be able to diminish their output when the expansion period is over, without finding themselves saddled with large overhead expenses left over from the period of high output. At the same time the extensions will still be available for use in any future time of stress and will be kept in such a state that they could be used again for production immediately the occasion may arise.

The War Years 1939-45 at Longbridge

Its a fact that many people suppose that, during the war, Car Manufacturers merely continued the business of producing automobiles, supplying them solely to the Government for the Fighting Services. This was so far from the truth, motor vehicles were still been produced in the war, in fact nearly 100,000 came of the production lines in this period.

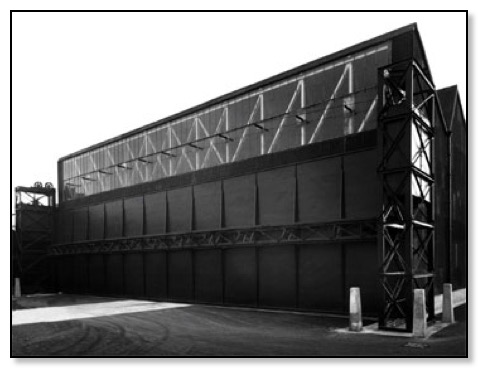

It was a very difficult time as output for peace had to continue, but the possibilities, at least, of war production began to unfold and the country had to be ready. As it became clearer that war was only just around the corner the first phase was the building of the Flight Shed at the corner of Lowhill Lane and Grovelly Lane. A contract for the erection of the Flight Shed, Low Hill Lane, Longbridge, between Austin Co. acting for the Secretary of State for Air and the builder Messrs Wilson Lovatt & Sons Ltd was signed early in 1937, work starting immediately. Next came the building of the Shadow Factory, Cofton Hackett Factory, but called the Aero by all who worked there. People who worked there were issued with square enamelled badges which were in deferent colours depending on which department you were working in, this meant you were not allowed in any other department. The badge shown below is rather unique in that it is round. (if anybody can give me a reason for this, please contact me) Although most people called it "The Aero" it tended to be called East Works after the War. The first aeroplane to be built, were the Fairey Battle. It was in September 1938 that the first plane built, took off from the flying ground.

Main Door where the Planes Emerged

Hurricane taking off from the Longbridge airfield

East Works with the Sand Bags

But the actual diversity of products and components was staggering, the Longbridge site provided anything from a simple machined shaft to a Lancaster Bomber.

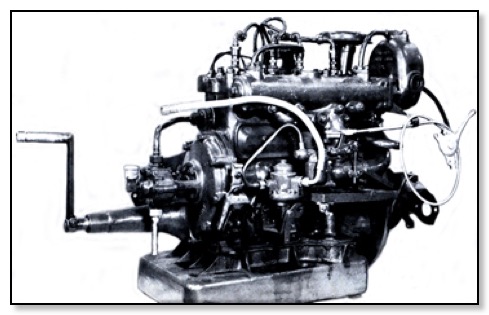

Some of the war time products were large, many were small, but all were vital to the war effort. In a normal year of peace, Longbridge would manufacture nearly 100,00 vehicles which would range on the car side from 8 HP to 28 HP, and commercials would be from small vans up to 3 ton trucks, also including industrial and marine engines.

Marine Engine for Life Boats

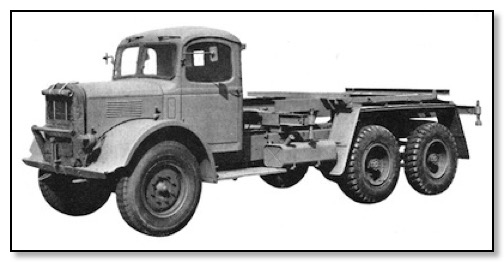

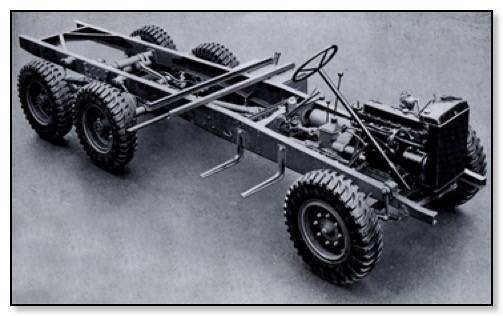

It is, therefore, not surprising to learn that Austin vehicles during the war met a large part of the transport needs of the British armies, and every week up to 500 army and other vehicles came off the production lines, ranging from 8 h.p. utility cars to 3-ton trucks, including four and six wheelers drive. Army breakdown and fire fighting vehicles. Along with Ambulances, R.A.F. tenders and troop carriers, Signals and Workshop units. By the end of the war the total number of such vehicles was over 120,000.

6 x 4 Austin Chassis

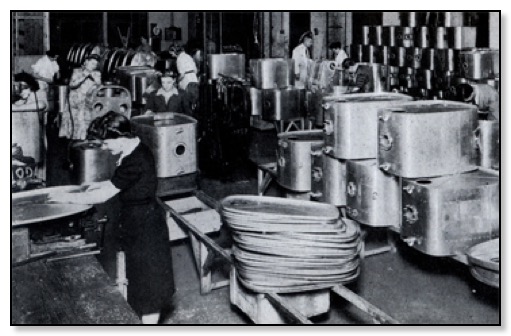

For the war in the air, Longbridge has also to its credit a formidable list of aircraft products. These ranged from balloon cable cutters to Beaufighter and Miles Master wing and centre.sections and Horsa glider fuselages, representing in all 5,000 aircraft. Additionally, Austin production included oil and fuel tanks for four.engined bombers to the tune of 15,000 incorporating 2,500,000 square feet of light alloy, and numerous small assemblies ranging from landing gears to components for Rolls Royce engines and Rotol propellers.

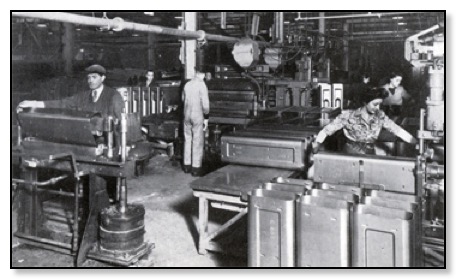

Oil and Fuel Tank Production

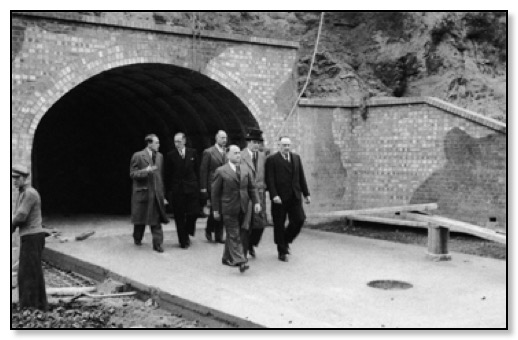

Also the process of digging out deep shelter tunnels in 1936 to accommodate up to 15,000 personal. The main tunnels were in the South Works and driven under the Flying Ground through the sandstone, a task undertake by mining engineers. As can be seen from the picture below they were larger enough to accommodate a 3 ton lorry. The ones in South Works were mainly built to act as a air raid shelter although some machining etc was also carried out. The ones next to the Shadow Factory were built for the main purpose of assembling Bristol Aero engines although it did have a Ambulance Station. So by the time September 1939 had arrived, the main tasks were in place and Longbridge could take its place promptly and efficiently to produce the items of War.

One of the Tunnel Entrances

For months before war was declared, production was slowly been changing so that it could be ready to meet the needs of our armed forces. It was a bit of a balancing act as the needs of peace time had to continue. By September 1939 the major infrastructure was in place, and Longbridge was now ready. The first task was the need to camouflage the factory and although everything had been planned in advance, this mammoth undertaking was achieved in just three day. So from the air the factory roofs of 120 acres disappeared into the countryside. The Lickey Hills is very close to the factory and people at the time would go and look at the panoramic view of the factory, were amazed to see how it blended with the countryside even down to having a road going across the site.

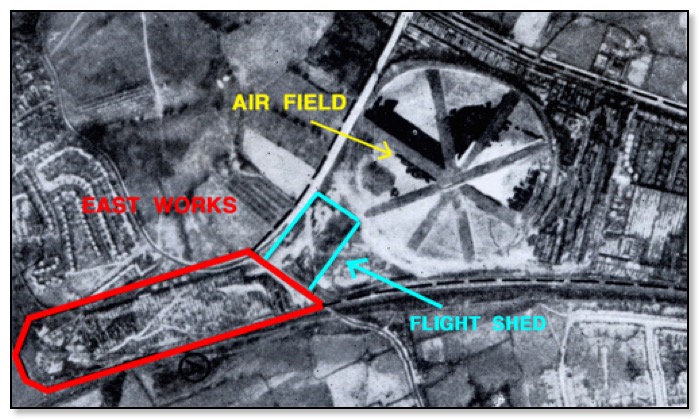

Aerial Picture taken by the Germans

As you can see from the aerial picture East Work and the Flight Shed have blended well with the countryside around. The Air Field is not so good, but note that the runways are like the spokes of a wheel, this was a brilliant idea as aircraft could take off what ever direction the wind was blowing.

It was now necessary to re-plan the tooling and production areas for the change over to munitions etc. Employment gradually rose, as contracts from the government came in and production increased so that Longbridge was employing over 32,000 workers. Even though the factory was well camouflaged, the Air Ministry was sure that an air raid was on the cards, as the Luftwaffe planes only had to follow the railway line. In fact only one daylight attack took place on North Works by the railway when a few employee was killed. To protect the site from attack some workers in overtime would be assigned to the Air Raid Precautions (ARP) and later with the Home Guard.

Because of the requirement of the Air Ministry, every new contract given often meant that new machinery had to be brought in, tooled up and the labour retrained. this was a ongoing event, which at times must have been soul destroying.

So what did the Longbridge plant turn out.

One of the necessities of war was the service helmets produced by the Austin presses to the tune of 500,000. The Jerrican which enabled the safe storage of fuel, and with its ease of pouring should have won a design award. Most of the 600,000 supplied to the forces were assembled at a factory in South Wales. The rest were assembled at a factory unit in Kings Norton, with all the pressings supplied from West Works Longbridge.

The Jerrican

Over 110,000 bogey suspension units and a large number of driving gear units for Churchill tanks were another ‘sideline’ so to speak. Although most of the Longbridge production was geared to the Army and Airforce, parts were also made for the Royal and Merchant Navy. Mine mechanism plates and depth charge pistols came to a staggering total of 440,000 units. Magazines for the Navel ‘Oerlikon’ gun amounted to over 110,000.

The Civil and Nation Fire Service were equipped with over 5,000 Austin 2 ton lorries of various body styles. Industrial engines of which about 20,000 were produced, with nearly half coupled up to drive a fire pump.

K2 Ambulances Finishing Line

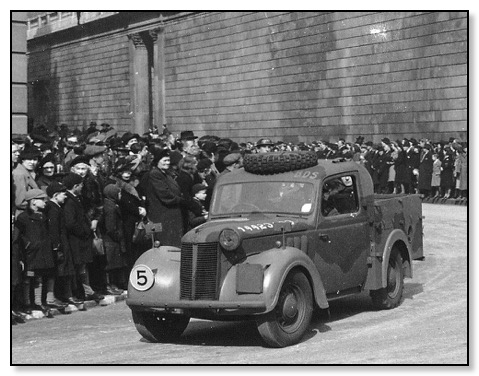

Austin 10hp Tilly taking part in the London victory parade in 1946

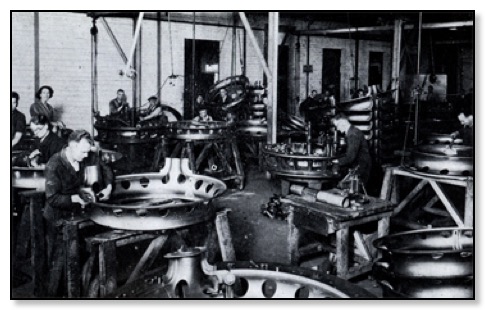

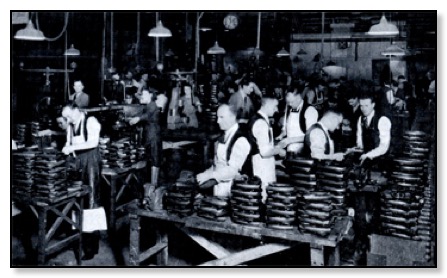

Exhaust Ring Production

Longbridge produced over 122,000 exhaust rings for the Bristol aero engines.

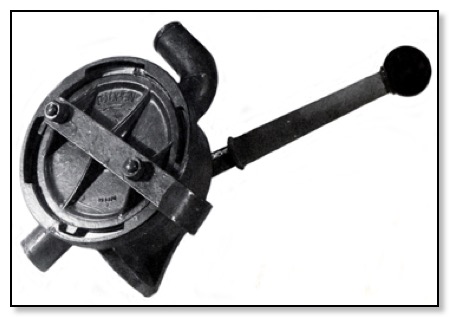

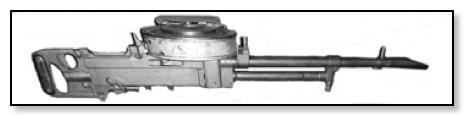

Although most of the items produced were fairly large, there were small items made that were vital, such as tails for 2501b., 1,0001b. and 4,0001b. bombs, some 300,000 Vickers and Hispano machine gun magazines were produced for aircraft atmament. One of the small items was the humble bilge pump which was with each airborne Life Boat on every Bomber. This very simple construction of a semi-rotary pump was designed and produced at Longbridge. It was self priming and should it draw up debris into the pump itself, by rotating the cover plate using the metal strip as shown any obstruction could be easily removed.

Bilge Pump

For the land war, additional to vehicle output' armour.piercing ammunition of 2-pounder, 6-pounder and l0-pounder types were produced to a total of 1,350,000 rounds ; allied to this was the output of 3,350,000 ammunition boxes. Magazines for machine or tommy guns also loomed large in the Austin contribution to the Army's needs' as with the Bren Sten and other magazines, upwards of four millions of these units were turned out'

Ammunition Boxes

Bren Gun MKI

The Bren Gun which was manufactured in Enfield London was rated as the finest light machine gun every adopted as it was reliable, robust, simple and accurate. It was in the West Works that a shop was set up to produce the magazine that held 30 rounds, with over half-a-million been made.

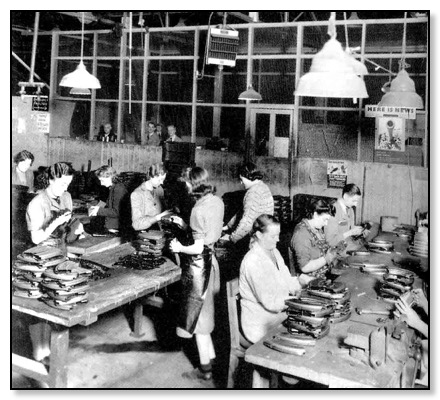

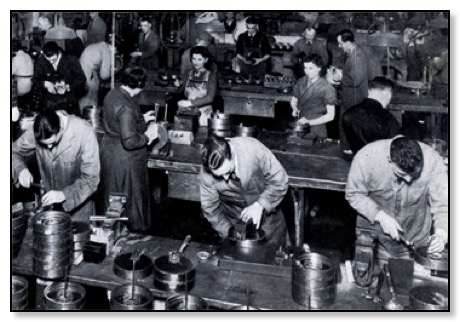

Bren Gun Magazine production West Works

Oerlikon & Bren Gun Magazine Assemble

The gun got its name from the designers (R. V. Shepard and H. J. Turpin) and the Enfield arsenal where they worked. Although it was ugly and crude, but been of simple design proved to be very reliable in the field. It was produced by the Enfield factory and also the BSA factory in Birmingham. The Sten magazines produced at Longbridge reached an incredible total of 1,759,000.

Sten Gun MKIII

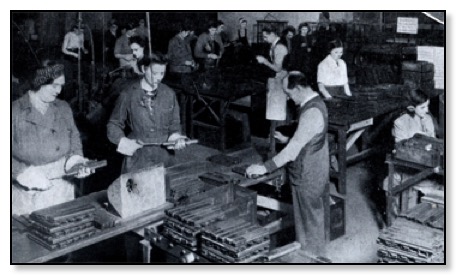

Sten submachine gun magazine production

Vickers K Machine Gun

This gun was originally supplied to the Royal Air Force as an observers gun. It was later taken up by the Special Air Service (SAS) often been used mounted on a Jeep. The early version used a 60 round magazine, with the later version having a 100 round magazine, which was the one produced at Longbridge. The total of 100 round Lewis magazines produced at Longbridge was over 421,000.

100 round Lewis gun magazine production

_____________________

Issued by the Ministry of Information in co-operation with the War Office

and the Ministry of Home Security

If the INVADER Comes

What To Do - And How To Do It

The Germans threaten to invade Great Britain. If they do so they will be driven out by our Navy, our Army and our Air Force. Yet the ordinary men and women of the civilian population will also have their part to play. Hitler's invasions of Poland, Holland and Belgium were greatly helped by the fact that the civilian population was taken by surprise. They did not know what to do when the moment came. You must not be taken by surprise. This leaflet tells you what general line you should take. More detailed instructions will be given you when the danger comes nearer. Meanwhile, read these instructions carefully and be prepared to carry them out.

A

When Holland and Belgium were invaded, the civilian population fled from their homes. They crowded on the roads, in cars, in carts, on bicycles and on foot, and so helped the enemy by preventing their own armies from advancing against the invaders. You must not allow that to happen here. Your first rule, therefore, is :—

IF THE GERMANS COME, BY PARACHUTE, AEROPLANE OR SHIP, YOU MUST REMAIN WHERE YOU ARE. THE ORDER IS " STAY PUT ".

If the Commander in Chief decides that the place where you live must be evacuated, he will tell you when and how to leave. Until you receive such orders you must remain where you are. If you run away, you will be exposed to far greater danger because you will be machine-gunned from the air as were civilians in Holland and Belgium, and you will also block the roads by which our own armies will advance to turn the Germans out.

B

There is another method which the Germans adopt in their invasion. They make use of the civilian population in order to create confusion and panic. They spread false rumours and issue false instructions. In order to prevent this, you should obey the second rule, which is as follows.

DO NOT BELIEVE RUMOURS AND DO NOT SPREAD THEM. WHEN YOU RECEIVE AN ORDER, MAKE QUITE SURE THAT IT IS A TRUE ORDER AND NOT A FAKED ORDER. MOST OF YOU KNOW YOUR POLICEMEN AND YOUR A.R.P. WARDENS BY SIGHT, YOU CAN TRUST THEM. IF YOU KEEP YOUR HEADS, YOU CAN ALSO TELL WHETHER A MILITARY OFFICER IS REALLY BRITISH OR ONLY PRETENDING TO BE SO. IF IN DOUBT ASK THE POLICEMAN OR THE A.R.P. WARDEN. USE YOUR COMMON SENSE.

C

The Army, the Air Force and the Local Defence Volunteers cannot be everywhere at once. The ordinary man and woman must be on the watch. If you see anything suspicious, do not rush round telling your neighbours all about it. Go at once to the nearest policeman, police-station, or military officer and tell them exactly what you saw. Train yourself to notice the exact time and place where you saw anything suspicious, and try to give exact information. Try to check your facts. The sort of report which a military or police officer wants from you is something like this :—" At 5.30 p.m. to-night I saw twenty cyclists come into Little Squashborough from the direction of Great Mudtown. They carried some sort of automatic rifle or gun. I did not see anything like artillery. They were in grey uniforms." Be calm, quick and exact. The third rule, therefore, is as follows:

KEEP WATCH. IF YOU SEE ANYTHING SUSPICIOUS, NOTE IT CAREFULLY AND GO AT ONCE TO THE NEAREST POLICE OFFICER OR STATION, OR TO THE NEAREST MILITARY OFFICER. DO NOT RUSH ABOUT SPREADING VAGUE RUMOURS. GO QUICKLY TO THE NEAR-EST AUTHORITY AND GIVE HIM THE FACTS.

D

Remember that if parachutists come down near your home, they will not be feeling at all brave. They will not know where they arc, they will have no food, they will not know where their companions are. They will want you to give them food, means of transport and maps. They will want you to tell them where they have landed, where their comrades are, and where our own soldiers are. The fourth rule, there-fore, is as follows:

DO NOT GIVE ANY GERMAN ANYTHING. DO NOT TELL HIM ANYTHING. HIDE YOUR FOOD AND YOUR BICYCLES. HIDE YOUR MAPS. SEE THAT THE ENEMY GETS NO PETROL. IF YOU HAVE A CAR OR MOTOR BICYCLE, PUT IT OUT OF ACTION WHEN NOT IN USE. IT IS NOT ENOUGH TO REMOVE THE IGNITION KEY; YOU MUST MAKE IT USELESS TO ANYONE EXCEPT YOURSELF.

IF YOU ARE A GARAGE PROPRIETOR, YOU MUST WORK OUT A PLAN TO PROTECT YOUR STOCK OF PETROL AND YOUR CUSTOMERS' CARS. REMEMBER THAT TRANSPORT AND PETROL WILL BE THE INVADER'S MAIN DIFFICULTIES. MAKE SURE THAT NO INVADER WILL BE ABLE TO GET HOLD OF YOUR CARS, PETROL, MAPS OR BICYCLES.

E

You may be asked by Army and Air Force officers to help in many ways. For instance, the time may come when you will receive orders to block roads or streets in order to prevent the enemy from advancing. Never block a road unless you are told which one you must block. Then you can help by felling trees, wiring them together or blocking the roads with cars. Here, therefore, is the fifth rule :

BE READY TO HELP THE MILITARY IN ANY WAY. BUT DO NOT BLOCK ROADS UNTIL ORDERED TO DO SO BY THE MILITARY OR L.D.V. AUTHORITIES.

F

If you are in charge of a factory, store or other works, organise its defence at once. If you are a worker, make sure that you understand the system of defence that has been organised and know what part you have to play in it. Remember always that parachutists and fifth column men are powerless against any organised resistance. They can only succeed if they can create disorganisation. Make certain that no suspicious strangers enter your premises. You must know in advance who is to take command, who is to be second in command, and how orders are to be transmitted. This chain of command must be built up and you will probably find that ex-officers or N.C.O.'s, N ho have been in emergencies before, are the best people to undertake such command. The sixth rule is therefore as follows:

IN FACTORIES AND SHOPS, ALL MANAGERS AND WORKMEN SHOULD ORGANISE SOME SYSTEM NOW BY WHICH A SUDDEN ATTACK CAN BE RESISTED.

_________________

The Essential Work Order

Labour shortage and the end of war.

During 1940, Bevin was unwilling to assume control of the direction of labour, but by early 1941 the shortage of skilled labour was critical. The Essential Work (General Provisions) Order of March 1941 required all skilled workers to register. The Ministry was able to prevent them from leaving jobs designated as essential, such as munitions, mining and agriculture. Another means of solving the skilled labour shortages was the dilution of skills through the abolition of trade practices and restrictions. Unions were traditionally opposed to this, but Bevin was able to suspend trade practices by promising to restore them after the war in the Restoration of Pre-War Practices Act of 1942.

In the war years, unions became closely involved with the government of the economy. In 1942, the Ministry of Production was established and set up production boards across the country. Consultative committees at factory level provided a means through which workers could advise management on improving productivity.

Cooperative industrial relations were encouraged by the government's cautious approach to wage restraint. In 1941, the White Paper 'Price Stabilisation and Industrial Policy' called for restraint, but little was done to hold wages down. The government sanctioned wage increases when directing labour to low-paid essential industries. Bevin pushed through the Catering Wages Act of 1943 to establish wage determination in an industry that had not been effectively unionised. The Wages Council Act of 1945 established councils to determine wages in individual industries.

During April 1944, there were a number of unofficial strikes in the coal industry. The government responded with Defence Regulation 1AA, which imposed a maximum five-year jail sentence and fines of up to £500. Although the number of unofficial strikes continued to rise up to 1945, the government never implemented the sanctions.

End of the war

By the end of the war, trade unions had grown substantially and were nearer government. The system of voluntary collective bargaining on wages and conditions had survived the rigours of wartime conditions. These factors were important influences on the nature of relations between government, unions and employers in the post-war period.