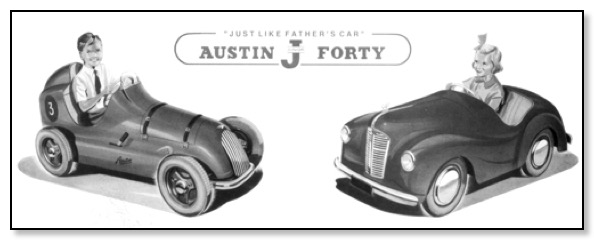

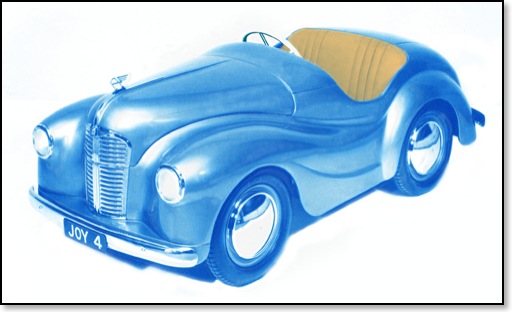

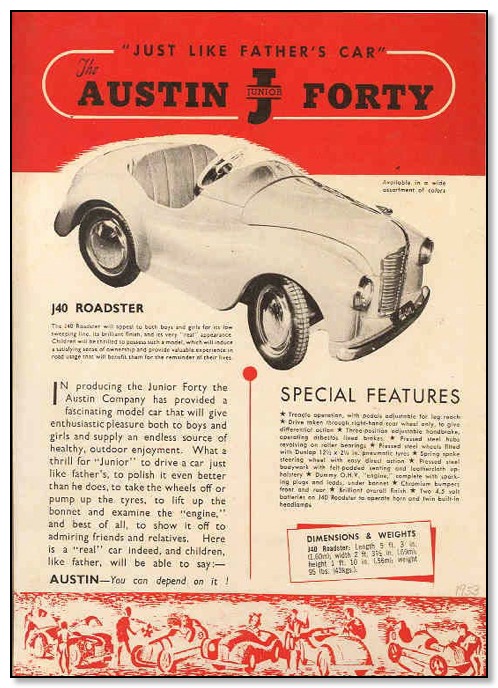

J40 Toy Car

A big thank you to David Whyley for the information on the J40

How did the J40 come to be produced?

It was in 1943 that Parliament passed an act that recognised that many miners were been struck down with what the miners called "The Dust" (pneumoconiosis’s). The Government decided to encourage employers to give ex-miners employment. Leonard Lord had taken this to heart and decided that those (in this case South Wales miners) who had been cut down by this respiratory condition could still earn a wage. It was stated that in 1945 there were over 5,000 miners suffering from this disease. The plan was that they would build a Toy Pedal Car based on the current models. To keep the cost down, it would use metal off-cuts.

It was Leonard Lord, Chairman of the Austin Motor Co who in April 1946 summoned Rod Phillips who was an Artist attached with the Post War Planning whose brief was to look into the future of how the factory would look in the Post War period. He was joined by Jim Blake who had joined him after serving in the war, (it was a government directive that for person who was employed before the war, his employer would have to offer them their old job back on returning to civilian life.

Both Rod and Jim had no experience of body design and the tooling needed. This is where a third member Alf Ash joined the team who had the expertise.

The team were given a disused workshop in South Works in which to set up a design office and experimental build. So it was down to looking at the specification.

a) Suitable for children in the age range four to nine.

b) Must be able to have room in the front for a smaller brother or sister.

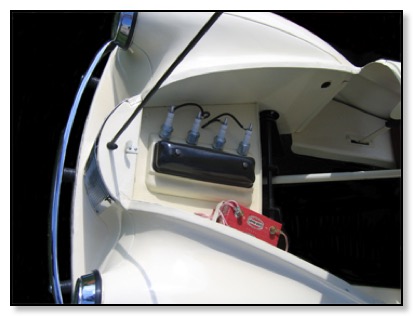

c) Bonnet and boot to open.

d) Lights that work along with a dummy engine

So starting from the bottom, the first think was to look at what was the smallest tyres available. This turn out to be Dunlop 12 inch cord tyres which were fitted on 8 inch wheels. The body had to mirror the range of full size models with the alligator bonnets, chrome grilles along with the characteristic headlamps.

Producing a full size car is easy as all the tools and processes are in place. The main problem, how do you produce a car for children, so it was necessary to take measurements of a child. Alf Ash was the only one of the team of three who had children, so his eight years child Marcia was measured that very night. From these measurements next day a full size 2D template was made. Now the engineering drawing could be worked on.

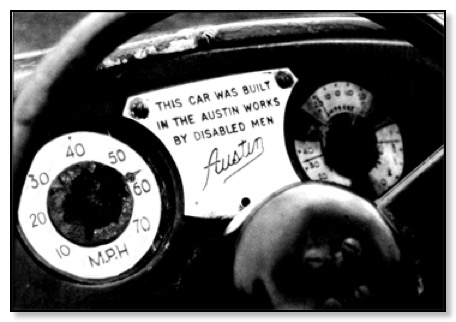

Leonard Lord who started the ball rolling made frequent visits to the workshop to see how things were progressing. He often made suggestions which were not always taken up. The launch date which had been planned for the Austin Progress Convention in June was getting closer, so it was decided that more staff were needed. This hole was plugged when two sheet-metal workers joined the team. The next thing was to design the facia, which had two dials, one the speedometer and the other split into three, Fuel, Oil pressure and Ammeter. An engraved plate said ‘This Car was built In The Austin Works By Disabled Men.’ This statement was incorrect as the cars would not be made at Longbridge.

The seats were constructed on a plywood frame to which springs were attached. This was then covered by brown leather-cloth then the full length pleats were stuffed with horse hair. This work was carried out in the trim shop.

Various other items were needed before the Pedal Car was ready to show to the public. A final coat of deep maroon paint was applied, a colour suggested by George Harriman.

So what was still missing, a number plate, but what shall we call the car? Although various suggestion were put forward, at the end of the day, Leonard Lord finally came up with JOY 1, because he said “This car is going to give joy to many children”

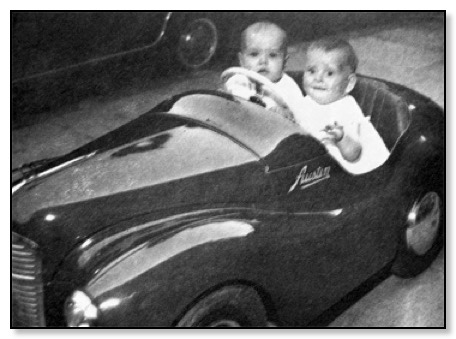

Photo call for Marcia in Joy 1

The next stage was to take the official works photographs, so the services of Alf’s daughter Marcia was needed yet again.

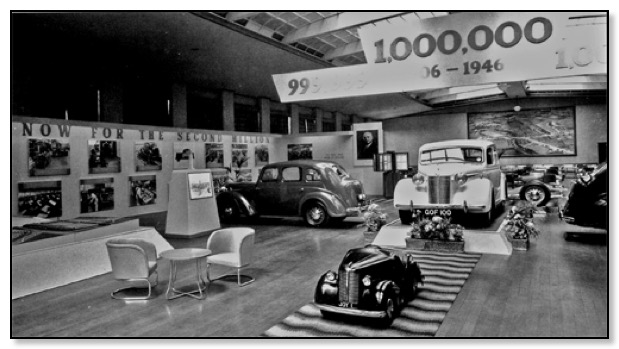

I referred to the Austin Progress Convention earlier, this was a mile stone in the history of The Austin Motor Company celebrating the One Million Car (Austin 16) produced at Longbridge, the date 25 June 1946. As Leonard Lord was coming to the end of his speech about the achievements made by the company over the 41 years, he said “ I have a little surprise”, where upon he unveiled JOY 1 and then went on to explain to the guests where they would be made.

Longbridge Old Showroom

So now it was on to the next prototype, JOY 2, this had to be made a lot lighter and be capable of being manufactured. Various changes were made, the main one was to improve the pedal system, by converting from bicycle motion to the forward backward system. With these changes made, the car was loaned out to management families to see how it would cope with the real world of children.

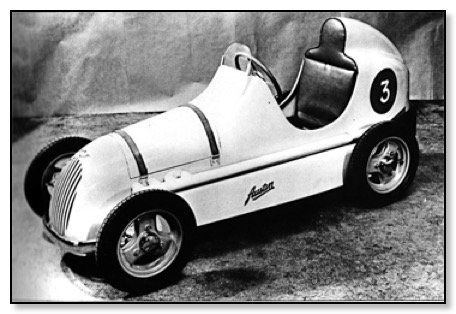

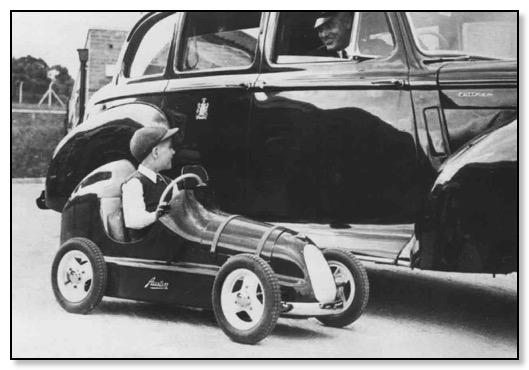

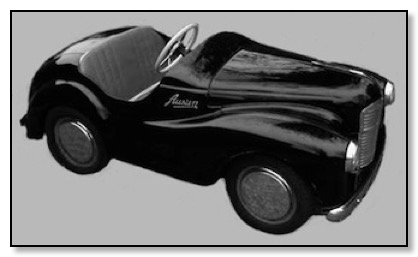

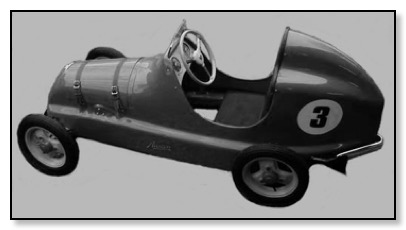

The next chapter was to look at a complete change of direction. Jim Blake decided it would be nice to build a model based on the pre-war Twin-Cam racers, so from memory (no pictures available) the project was started and called Joy III. A lot of the mechanical components could be used, the wheels were the same, but instead of the large hub caps a Austin 8 petrol filler cap was used. As it was a single-seater it was necessary to reduce both track measurements, with the rear shorter than the front. It was finished in white with red wheels and trim and brown leather straps holding the engine cover in place, a decal displaying the number 3 giving it a racing image and also showing that it was the third prototype made.

JOY III (Pathfinder)

It was at this junction that the team moved from South Works to East Works, known to most of the workforce as the Aero Factory, into a new workshop which they christened Joy Car Department East Works. It was around this point that George Harriman, Works Manager asked Jim to take JOY III down to Selfridges in London to find out first hand if they would be willing to sell them.

Unknown to the team the Austin Experimental Department had been given the task of producing a wooden mock up of a pedal car, using the rear end of JOY 1. The front end would be based on the A40 Devon which had not been announced yet. Jim’s first reactions on seeing the model, “was we will never sell that, it's a monster”.

It was time to start on the next phase, JOY IV which would have a front end like the new A40 Devon. This meant that they needed access to the full size drawings, which were not forthcoming, but were allowed drawings of the Devon grille.

Although having seen the full size prototype, it was a case of memorising what they saw and transferring it on to the JOY IV.

Soon it was time to show it to management, so an appointment with George Harriman was arranged. The unveiling ceremony was well received, its metallic blue body must have looked quite stunning along with the light fawn leather trim.

B/W Photo Re-coloured

Production Stage

Leonard Lord had got his concept made, so the small team was disbanded and no further prototypes were made. Jim Blaikie job now was to get new members for this team who could turn the two prototypes into a production model. The first task was to break down the body into separate panels that could be pressed out and then spot welded together. It was now that tooling and production of JOY III & JOY IV had to take place. It was around this time it was decided to call JOY III by the name Pathfinder and JOY IV would now be called JOY 40, this was soon changed to J40, with the J standing for Junior.

The tooling was ordered for both models, it was then that various supplier’s, such as Dunlop and Lucas were asked to quote. One interesting contract was with Champion to supply sparking plugs which were actually faulty, so they probably came free. Every item would have to receive a part number, with some parts common to both models, like wheels and tyres.

Although the original idea was to use up scrap sheet metal from Longbridge, this was only possible for small parts, the larger panels would be produced from fresh steel strip. The Government were willing to pay for a new factory, so it was decided to build the factory at Bargoed in Wales. To set the factory up second hand presses a total of nine were send down from Longbridge. The Body Sides needed a larger capacity press and so these panels were pressed in West Works Longbridge.

Whilst this was going on the prototype team were disbanded, each one going back to their original jobs, Jim Blaikie actually leaving the Company in the early part of 1949.

Junior Car Factory Bargoed

Setting up the factory

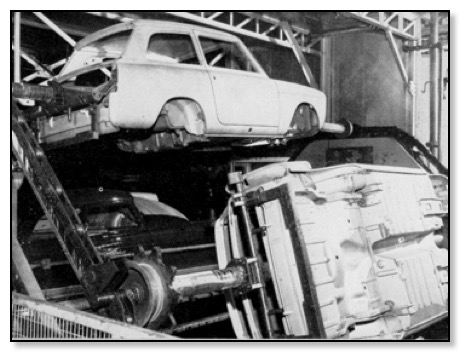

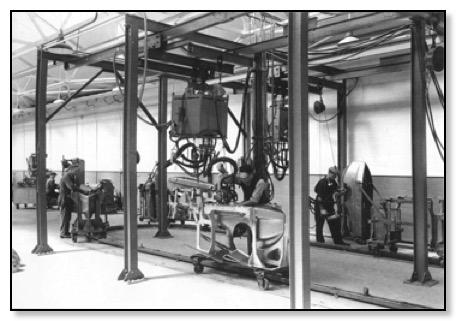

The factory in Bargoed was starting to take shape, and covered an area of 24,500 sq ft. This included a production area along with stores, offices and canteen. Although the Government funded the factory through the Board of Trade, Austin still had to pay rates, but this was reduced to 50% because only disabled staff were being employed on the production side. It was decided to get the plant up and running by Christmas 1948, in fact things were slipping badly and the factory was not finished till January 1949, with a manager installed and various staff from Longbridge arriving to install the necessary equipment. One interesting piece of new equipment was a process supplied by Carrier Engineering for the preparation prior to painting of the bodies. The process was called Rotodip which the company were hoping to get Austin to installed at Longbridge. The process involves putting the welded body on to a shaft that rotates as it goes through baths of metal preparation chemicals. The management at Longbridge must have been impressed as the process was later installed in West Works.

A40 Farina's going through the Rotodip in West Works

One of the men who came from Longbridge at the start of the project is factory foreman, Mr T Gilbert who had been a sheet-metal worker in West Works. 'It's a great thing for these men to have a job. I've had men here who had been unemployed for five or six years. This place does a lot for their morale. None of them know anything about the work here when they arrive, but they are keen to learn, settle down quickly and do a very good job.' In the beginning some 40 or 50 men started production and by early 1951 this had almost doubled.

An up to-date medical centre was essential for the work force who would be employed, and staffed with a nurse and a part time Doctor. Twice a year the hospital in Cardiff would send a team along with a mobile X-Ray machine, to check on the workforce.

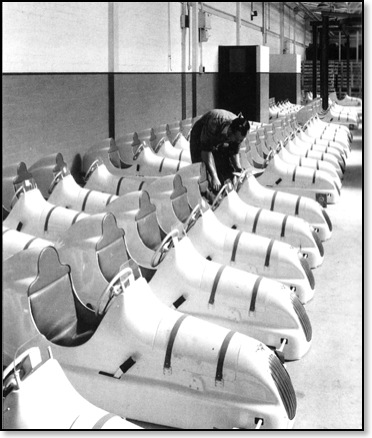

All in line just waiting for the wheels

It was decided in the early stages to make the Pathfinder version first, the main reason for this is that the main body was only two pressings, and these were being made at Longbridge. With less parts than the saloon version it was easier to bring it out first. The first public advert for the cars was by Selfridges in June 1949 although the company had contacted their dealers in mid May stating that “Delivery of Pathfinders will commence almost immediately, and the ‘Joy Roadster’ will be in production in about three months time.” Supplies were slowly being built up, ready for the official opening of the Factory in July 1949. The press were quite intrigued by the cars and gave the company much valuable publicity, although I don’t think there were any free samples given away. It appears that the Pathfinder was joined by the Roadster at the end of 1949, which was just right for the Christmas period. The cost of the Pathfinder was £25. 4s with the Roadster at £20. Production figures for the two models are unknown, as no figures were kept before 1955.

In the early years the workforce was around the 110 mark, but in 1953 suddenly increased to just under 150. From then on it rose nearly every year until it reached a peak in 1965 employing 514. The reason for this increase was that over the years the factory had the presses and welding equipment to produce other small components needed by other factories in the BMC empire. Parts such as rocker covers, timing covers and number plates were the main items.

The miners having worked in different pits, were now doing work that meant learning new skills. It must have been quite alien working in a factory, if you had only ever worked in a mine. One thing that some found hard to except were the hours starting at 8 am and finishing at 5 pm, because they were used to working from 6 am to 2 pm.

It was on the 12 January 1962 when disaster hit the factory, the night shift around 10pm were aware of the smell of gas and reported it to the foreman. Minutes later there was a loud bang and the whole roof was blown off in the paint section. A temporary partition was erected closing off the paint section so that the rest of the factory could continue. Although the workforce were shaken no injuries were recorded, and everyone carried on, as there were orders to get out even though it was very cold.

In late 1962 an additional factory unit was built to produce the door pockets for Mini and 1100 models. But in 1971 it was decided to close it down because the glue been used was affecting the health of the workers.

On the 15 September 1971 the last of the Joy Cars were made, all of them going to UK customers. At this point the production total from 1955 to 1971 was 32,098. It is believed that the figure from 1949 to 1955 was about 1,500 Joy 40 and over 3,100 Pathfinders.

Assemble Process

As stated earlier, the Pathfinders were the first to go into production. The main components were the body, trim, front and rear axles, pedal assemblies and wheels and tyres.

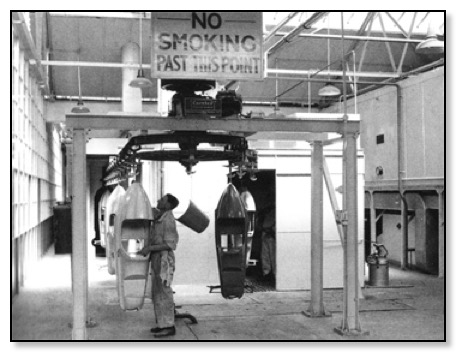

With the Pathfinder it only had two main pressings which were supplied from Longbridge. The pressings were spot welded together along with the facia and seat panels. As you can see from the picture below, after having a pre-treatment via the Rotodip and primer it passed to the paint spray booth. It would be hand sprayed and as can be seen in the picture the bonnet travelled separately. They were available in Cream with Red Trim and also Wheels and Grille, the other option was Red body with Beige/Tan Trim and Silver/White wheels and grille.

Paint Department

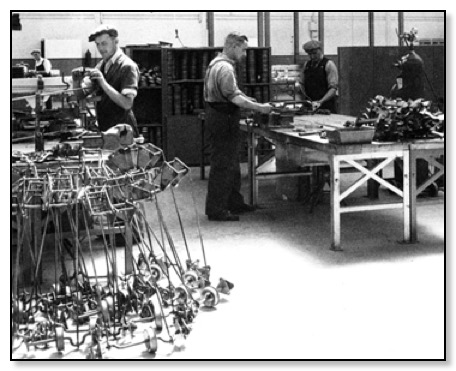

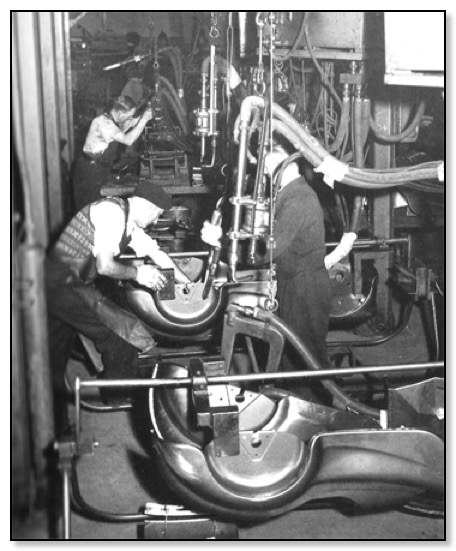

Assembly of the Pedal Mechanism

This shows assembly of the various items, including the parking brake which when operated pulls a band round a drum on the rear axle. The body is supported by a jig.

Welding Line

Here we see both Pathfinder and Saloons

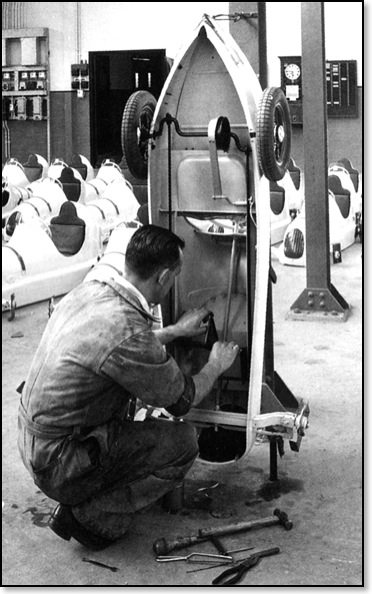

Assembly of the saloon on jigs which could be turned over to work on the underside

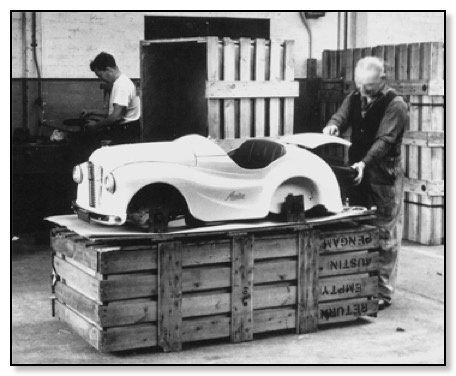

Packing the J 40 for export

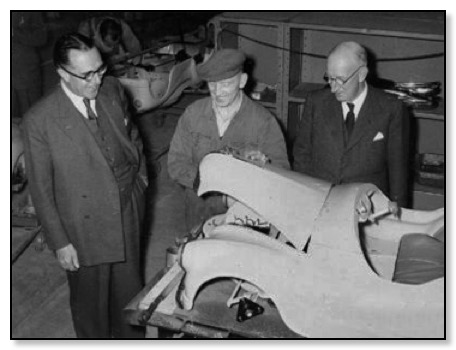

Minister of Labour, Lord Monkton on the left visiting the factory

along with Austin chairman Leonard Lord.

Photo call for the last one made

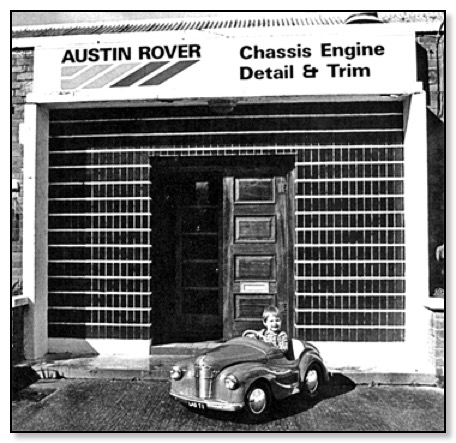

You’re never too early to start

The above picture shows a model of a Heenan & Froude Rolling Road which was most likely built for a exhibition or for demonstration purposes using a J40 car. Heenan & Froude were based in Worcester and were the main producer of Engine Test Facilities - Rolling Roads at Longbridge in Experiment Departments and for Production.

_______________

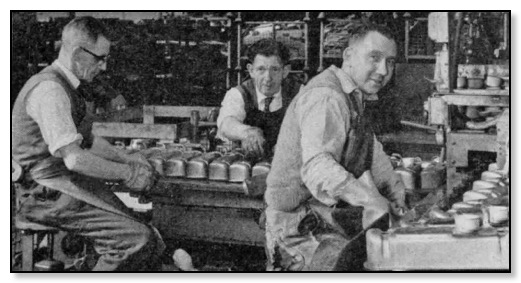

Bargoed Small Pressing

When the first ex-miners started work at Bargoed, the Austin Joy Car was the sole production item. But over time the factory has assumed an increasingly important role within BMC. The small factory is responsible for the production of valve-rocker cover and timing-chain cases for all the ‘A’ and ‘B’ series engines. The monthly production of these two components has risen over the years and now averages 43,000 of each component although recently a record of 69,000 was set up. ‘These two small, but vital, engine components are the major part of our production,’ said Mr J A Hudson. In addition 16,000 number plates of all types for vehicles ranging from the Mini to commercials, and 8,000 fans. Other components including such things as dynamo brackets, petrol-tank straps and crankcase covers.

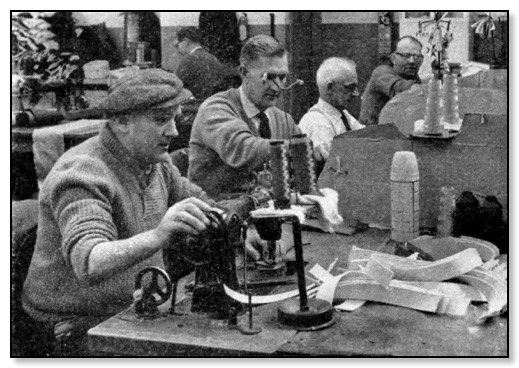

Another range of products produced were seats for commercial vehicles, the A35 and the half-ton vans plus KD seats – and tilt covers for the the Mini pick-up. Other small items made in this department include battery straps and door check straps, this diversity of products emerges from one building. The single storey structure with a production area of some 11,000 square feet accommodates a press section, tinning section, welding section, paint shop,, upholstery and trim department, and the assembly area for the pedal-cars.

All age groups are represented in the factory although the average is high. ‘The men come here with no previous experience and our biggest training session is on trim. It is a terrific change for a man, used to hewing coal for perhaps 40 years, to start handling cotton and a sewing machine,’ said Mr Hudson. These men are very adaptable and, what is perhaps more important, always anxious to learn because they are keen to work. In this part of Wales unemployment is still a very real problem, particularly for men suffering from this disease. They must do fairly light work which imposes a strict limit on the sort of jobs they can do.

In January 1962 a powerful explosion in the paint plant injured 16 workers and ripped off nearly half of the factory roof. A temporary partition was erected closing off the paint section so that the rest of the factory could continue. Although the workforce were shaken no injuries were recorded, and everyone carried on, as there were orders to get out even though it was very cold.

By eight the following morning senior engineers were there from Birmingham to put the damage right as soon as possible’ said Mr Hudson ‘apart from some of the painting, we were back to full production within a week. ‘The biggest single factor in this quick recovery was the co-operation of the men, they worked under adverse conditions and were just as anxious as we were to see the factory once again getting back to normal.’

Although the factory stopped making the J40 in 1971 it did continue to produce small metal pressings for Longbridge under Austin Rover and then for Rover Group, but closed down on the 30 April 1999.

THE LAST JOYCAR

Here we see the LAST Joycar body been built up on special Jigs.

Spotwelding being carried out by John Morgan, and David Marsh.

THE final touches are now being put to the last batch of cars which have served a discriminating and highly critical sector of the 'motoring' public since 1949.

When the last 165 are completed they will have brought the total production run of this vehicle in over 20 years to 32,100. Yet another vehicle will join the Minor, the Oxford and Cambridge, and more recently the Austin 3-litre as something to be looked back on with pride and perhaps affection.

'It's a grand little car,' agree the men who have built it. When in 1949, the Austin Motor Company founded a factory in the heart of the Welsh mining valley just to make it, a few eyebrows were certainly raised.

For the launching of the Austin Joycar was a radical departure for a major motor manufacturer.

SCRAP

It was planned to use scrap materials to build a child's pedal car at the special factory at Tiryberth near Bargoed, a plant which would offer employment only to miners who had been compelled to leave their careers underground through disability.

Today there are two factories at Tiryberth and the ex-miners now produce all of Austin-Morris's valve rocker covers, certain soft trim items and detail parts.

And, of course, the Joycar, though this has become the standby job as the emphasis has changed from the pedal car as the sole item of production to the present range of components for production vehicles.

What is now known as the Austin Joycar, and will be remembered as such, started production as a very different vehicle as Mr. Elwyn Stephens recalls.

'I joined the plant in 1949 when production had just started on the Pathfinder, a pedal car designed on the lines of the Seven Racer,' he explained.

'The bonnet was held on with leather straps, the front wheels protruded away from the body and had separate mudwings, and there was a flared hump behind the driver.

'

Dillwyn Picket started in 1961 making trim for the little car.

TO LAST

But even in those early days what went into a production car went into a Pathfinder-standard gauge metal and rigidly constructed pedal mechanisms really built to last.

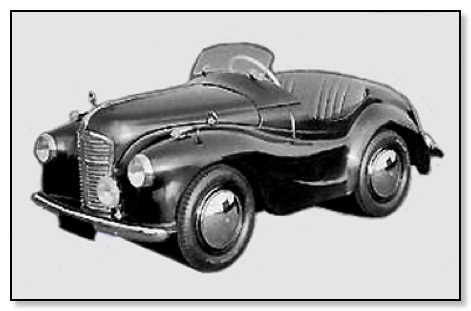

But after a year of production the Pathfinder was superseded by the Joycar designed on the lines of the Austin Devon and it is in this shape that it now leaves the junior motoring scene.

'But you will see plenty on the footpaths for years to come,' chuckled Jim Burrows, who also joined the Pathfinder assembly line in 1949.

'The Joycar will take a lot and I would reckon that 10 years' hard wear might just about finish one off.'

Many of the men at Tiryberth who spot-weld fans and press rocker and chain covers learnt their trades with the pedal car and are openly sentimental about the fact.

Trimming seat for vans is Jim Sheen's regular work, but of course the miniature seat squabs for the Joycar have come along quite frequently.

The Joycar has been used by Royalty, it has built up its own export market, notably in Canada and Denmark. Ingenious parents have fitted petrol and electric motors to them for use on private roads.

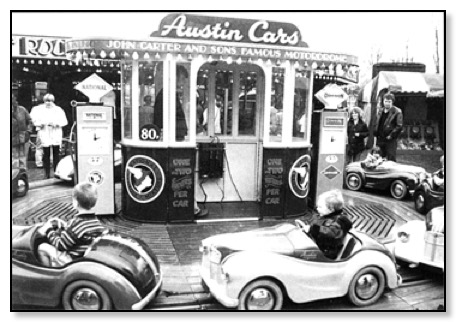

Police forces have used them to train youngsters how to behave in traffic. Many can still be seen firmly bolted to fairground roundabouts.

Part of the last batch will go to a holiday camp organisation and will perhaps be used by children of British Leyland employees, this summer. One might have on the plate inside the boot the number 32,100.

That will be the last Austin Joycar !

'It is sad to think this is the last batch,' said Jim as he carefully fitted the padded squab to the seat panel, a job that tests the eyesight and nimble fingers of a man 25 years in the mines.

'The youngsters get as fine a job of work in their little car as their dads get with their big Austins,' he declared proudly.

After-sales service and special orders have been as much part of the Joycar picture as they are for the large Austin Morris products.

SPECIAL

Jim Sheen who learnt trimming on the Pathfinder, completes a rear seat

for the last of the Joycars, with foreman Ted Grendon looking on.

A special modification was made to one Joycar so that a spastic child could drive it with ease; 'write offs' have been sent back to Tiryberth for repair and letters from satisfied users are displayed as proudly as those held at plants which make the Minis and 1100s.

Vehicle safety is a recurring theme and as far as the Joycar is concerned the protection of the young driver has always been of prime importance. On present day limousines projections on the bonnet are illegal unless they are designed to spring back or collapse under impact. The flying A on the Joycar bonnet was discontinued for this reason.

'We don’t want the youngsters hurting themselves now do we,' said one Joycar worker.

A feature of the car has been electric lights and a horn-supplied by Lucas of course - and pneumatic tyres by Dunlop and a powerful handbrake.

'There is real stopping power there,' explained Albert Astoh as he fitted the hand-brake linkage to a brake band lined with solid brake shoe material.

The plugs under the bonnet can be removed but it has never been recommended that the adult motorist should rob his son's Joycar for a cut-price engine boost.

They are plugs rejected for regular use and passed for Joycar use only.

__________________________

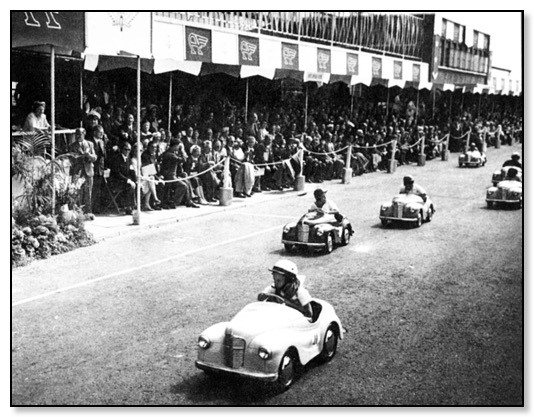

The Pedal Cars were also used mainly at fair grounds

This shows a ride that was built in 1955 by Hayes Fabrications of London, it includes 10 cars that are connected together to form a train. Number one and number six cars have a 110 Volt electric motor driving the rear wheels. This actual ride was restored to its former glory by John Carter.

GENERAL SPECIFICATION:-

Treadle operation with pedals adjustable for leg reach. Drive taken through right-hand rear wheel only to give differential action. Three position adjustable handbrake, operating asbestos lined brakes. Pressed steel hubs revolving on roller bearings. Pressed steel wheels fitted with Dunlop 12.5in x 2.5in pneumatic tyres. Spring spoke steering wheel with easy direct action. Pressed steel bodywork with felt-padded seating and leather cloth upholstery. Dummy OHV engine complete with sparking plugs and leads, under bonnet. Chromium bumpers front and rear. Brilliant overall finish. Two 4.5 volt batteries to operate horn and twin build-in headlamps.

DIMENSIONS

Length 5ft 3in

Width 2ft 3.5in

Height 1ft 10in

Weight 95 lbs

J40s used in Salzburg training scheme

All lined up in Toronto's Safety Village

3 year old Bernardo showing off his J40 (Argentina)

On 9 July 1955 Longbridge celebrated its Golden Jubilee.

Here we see the winner of the final race, whose prize was to keep the car he drove.

Special J40 present to Prince Charles (1952)

Note the various extras: windscreen, wing mirrors, number plate, side lights & spot light.

Imported into Argentina around the end of the 1940s.

_______________

A Small Boy's Dream, Cuba 1958

In 1958 in Havana Cuba, (prior to the communist coup) there was a huge (4 stories high) and prestigious department store named "El Encanto" that had a whole floor devoted to toys. I was 8 year old at the time and my mom used to leave me at the toy floor while she shopped in the other floors. This happened at least every other Saturday afternoon.

Naturally during my visits I kept close tabs on anything new that I would like my parents to buy for me.

One day I discovered there was this beautiful Austin pedal car, complete with headlights, horn and a boot. It even had a key to turn on the electrical system. I was besides myself, and started looking for the price tag and found it hanging from the steering. The price, if I remember correctly, was $300. (I can close my eyes now and still recall it perfectly in every detail).

At the time cuban pesos had the same value as the US dollar. Needless to say, I knew right then this would not be an easy task to sell to my parents, who usually shunned extravagant excesses like this. A real used car could sell for just as much.

I fruitlessly spent months trying to persuade my dad to buy it for me, but then one day he surprised me with another car he bought for me. It was an ugly contraption with a "modern" american style fibreglass body, (almost like a corvette).....but it had an important difference. It was not as nice or sophisticated as the Austin but it had a real engine ! ...Yes an engine from a lawnmower. These were made in Miami and were brought over to Havana by the hundreds.

The Austin was light green, my contraption was red. I hated red, but I became the most popular kid in my block by virtue of my red car with its gas engine.

In 1960 the beautiful department store was torched and destroyed by the communists in order to blame the US for "sabotage".

The Austin was still there the day of the fire.

I have never forgot that Austin.

Cordially,

Alfred.