Austin Tractors

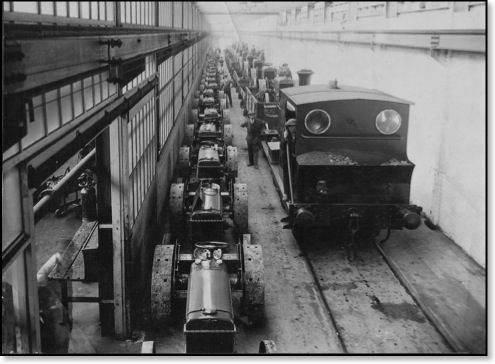

Tractors outside North Works

Herbert Austin was a member of a committee, set up by the government to look at producing a UK tractor, as at that time they were been imported from America and not really suited for the small farms in England. To supply the UK with tractors in WWI, Henry Ford agreed to place all his patents and some of his staff at the government's service free of charge. His only proviso was that the tractors should not be sold. All parts of these machines were produced in the United States and shipped to England for assembly at the government workshops in Manchester. This all took time, so Austin took the opportunity of selling American products because, at that time, his works were only producing for the Ministry of Munitions.

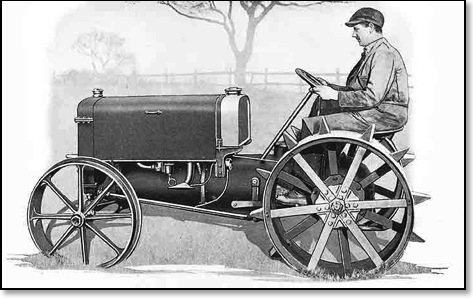

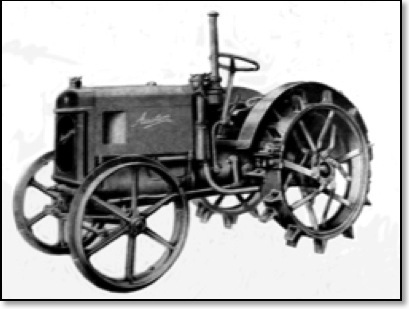

Early catalogue drawing

When the Fordson MOM tractor was available in 1918 and became very popular, it was time for Austin to bring out his own version. So using the Heavy 20 engine which could be ordered as either a petrol only engine or as a dual petrol/paraffin version. The dual system was common practice for tractors, which meant they had two fuel tanks both connected to a two-way tap. When starting from cold you would use the petrol, when the engine had warmed up you could turn the tap so that it was now running on paraffin. The reason for this was the fact that there was no tax on paraffin. The engines were considered to be more powerful at 26.5 HP @ 1,000 RPM (petrol version) and also more refined than the Fordson, but did not have the reliability. When running on paraffin the power output was reduced to 23.7 HP @ 1,000 RPM. It was launched in 1919, with production building up slowly so that in week ending 12th June 1920 sixty-six tractors had been produced.

Loading Tractors onto Railway Wagons for UK Delivery

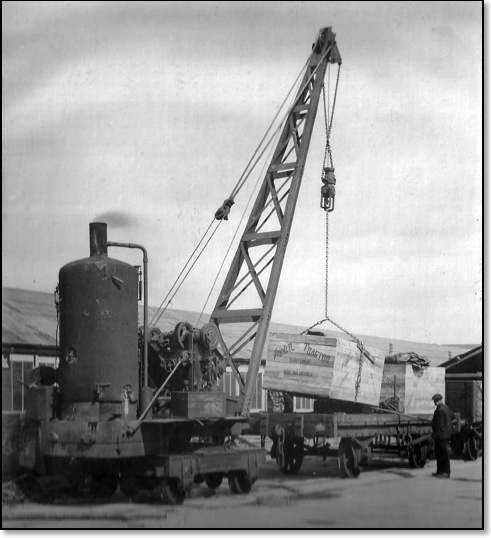

Steam Crane Loading Tractors For Export

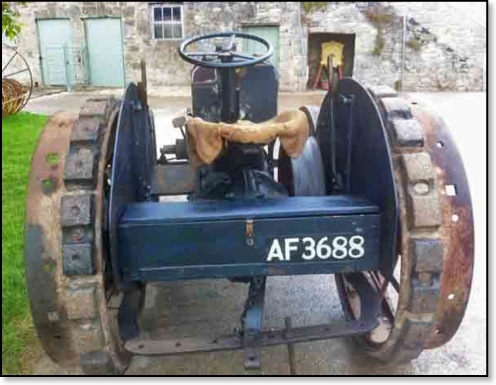

Austin Tractor Trials

The tractor above was produced in 1919, Serial No. 815

Note the rubber blocks attached to the rear wheels

Approximately 1,500 tractors were built that year at a selling price of £300 to £360. The America Fordson was been imported and sold at roughly the same price, but they were subject to a import tax of 33%, this duty was removed allowing the Fordson to under cut the Austin considerable. Austin had to follow suit and slashed price to £225 and then to £195 but the boom, as far as he was concerned, was at an end. As demand for tractor in France was high, but the Government imposed heavy duties on imports.

"To conserve the success gained by the Company’s Agricultural Tractors in France, and to overcome the high duties and rates of Exchange, and the difficulties and expense of transport, and also to meet the natural desire of the French farmers to purchase tractors made in France, the Board decided during the past year to increase the capital of the French Company known as ‘Sciete Anonyme Austin’ 10,000,000 francs, and to establish and equip a factory there.

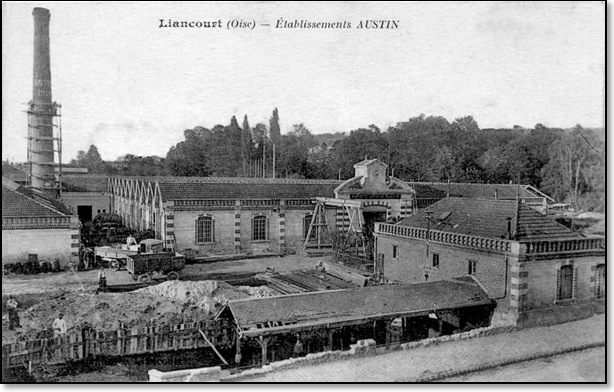

Liancourt Paris

A very suitable factory was purchased by the Company’s Agricultural Tractors in France, situated on the main Nord Railway, midway between Amiens and Paris, in a district noted for its industrial advantages. The whole of the necessary power plant, machine tools, jigs and gauges required have been sent over from the Longbridge Works, and are now installed and manufacture commenced. An output of 2,000 tractors per annum is anticipated and satisfactory arrangements have been made for the sale, over a period of five tears, to the eminent form of French Agricultural Engineers – T.H Pilter, Paris. The Austin Motor Company Limited, own about three-fourths of the capital of the French Company, and will receive suitable Royalties for the use of their Patents, Trade Marks, Goodwill, etc

With sales of tractors initially handled by T H Pilter of Paris, who have Depots and Agents throughout France and the French Colonies. But in the middle of January 1921, after delivering about 200 tractors, and although contracted for the output of the Factory for a period of 5 years, suddenly stopped taking delivery, and so manufacturing had to cut down to almost nothing until a new selling organisation could be set up.

Austin estimated that additional funding will only be required for short period, say from 1-2 years in order to enable the Directors to complete the establishment of a Sales Organization. In order to keep the factory going at a remunerative rate during the slack season of the year, the manufacture of other agricultural machines is being undertaken for which the plant is suitable, including a small tractor cultivator for vineyard use.

French agricultural experts singled the Austin vehicle out for special praise, which no doubt helped sales, the main components coming from Longbridge. In 1926 the catalogues were showing a price of £225 for the normal tractor or £285 for the 20 ton road-haulage version. But sales did not increase as projected, so around 1932 production ceased at Longbridge but continued in France. In fact tractors from the French factory were imported in to the UK in small numbers up to 1939, but in about 1951 the factory closed down. The main reason for its demise was that it could not compete on price compared with the Fordson.

It appears that around 1918-9 an American tractor company called F C Austin Co (Inc) Chicago was taken to court by the Austin Motor Co because of using an allegedly deceptive name.

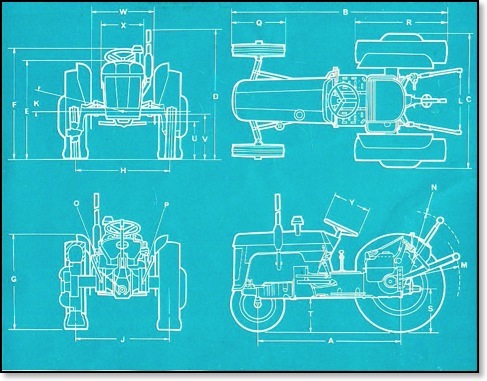

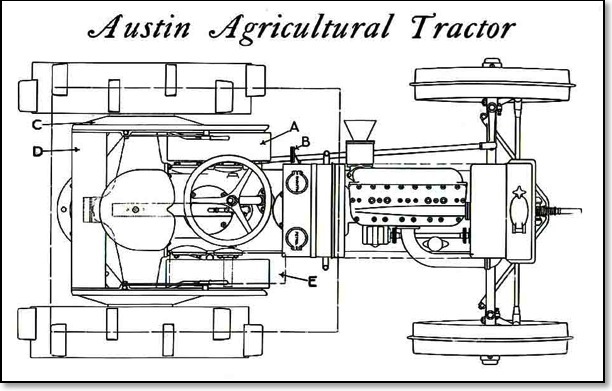

Fig. 1 Plan

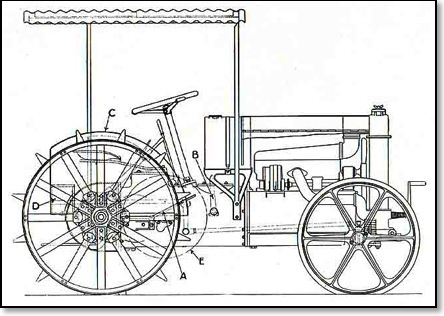

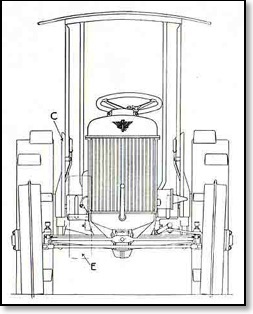

. . . . . . . . Fig. 2 Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fig. 3 Front

he above drawings shows various changes that have been made since the experimental tractor. The back wheels are increased in diameter from 3' 0" to 3' 6", and the rims are narrowed from 14" to 10", which has been found to be a more suitable width for general use. The seat, steering wheel and change-speed lever have been placed in more convenient positions. Foot rests (A) have been added, and the clutch pedal (B) is of the push diameter is fitted. The wheel guards (C) and brakes are shown in the drawings, and also the canopy, which is an extra. A large tool-box, which connects the wheel-guards, is shown at D. The detachable belt pulley is indicated at E. The radiator filler-cap is of a special pattern and of very large dimensions, so that water may be poured in from a bucket or similar receptacle. in Fig. 2 the bonnet is shown broken away, so that the engine may be more clearly seen, and in Fig. I the canopy and bonnet is merely indicated by dotted lines for similar reasons.

Specification

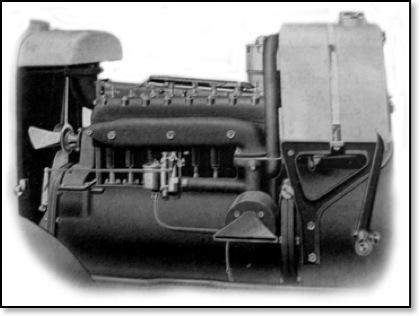

Engine: There are four cylinders. 3. 3/4 in. bore by 5 in. stroke (95 x 127 mm). which develop 25 h.p. at 1200 rpm. when paraffin is used as fuel, and 25.5hp at 1000rpm on petrol. The cylinder costing is of the monobloc type and is fitted with detachable head. The crankshaft is supported on live five bearings, and the whole engine is of very simple and substantial design.

Cooling: Is by means of the Thermo-syphon system-the radiator being carried at the front of the engine and cooled by a large rear-drive fan, all hearings being enclosed.

Vaporiser and Fuel Tank: The vaporiser is exhaust-heated and the fuel is fed to it by gravity. The fuel tank has a capacity of approximately 10 gallons. The motor is started up on petrol, for which a small subsidiary tank is provided on the fuel tank.

Air Cleaner: An efficient air-cleaner is provided.

Ignition: Is by means of high-tension magneto.

Lubrication: Is by means of a gear-pump, which feeds the main bearings.

Governor: A centrifugal governor fitted.

Clutch: The clutch consists of a steel cone engaging with detachable Ferodo segments (Austin Patent).

Transmission: The first motion is by bevel gearing; the change speed gears and final drives by spur gearing. All gears are of forged steel, case-hardened and run in oil, and will therefore be found to stand exceptionally heavy working strains. The shafts are carried in roller bearings.

Speed: 2.5 to 4.5 mph. with the engine running at 1200 rpm. Provision is being made in the gear-box for a third speed of 6.5 mph. if required. Reverse speed, 2 mph.

Brakes: There are two independent expanding metal-to-metal brakes, which are fitted to the rear wheels.

Belt Pulley: This is a large detachable split steel pulley to take a 5 -tn. belt, and is capable of operating a 54 in. thrashing machine or other machinery.

Steering: Is of the worm and sector type, and is enclosed in the main casing.

Wheels: Rear, 42" x 10" face: front, 30" x 6" face.

Wheelbase: 5' 8.

Track: Rear. 4 ft. and front 4' 3" (centres).

Length: Overall 9' 2".

Width: Overall 5' 1".

Turning Circle: 22 feet.

Weight: 25 cwt.

Draw Bar Pull: On low gear this Is 3,000lbs., and is ample for ploughing three furrows 10in. wide and 6in. deep in practically any land. These results are obtained when using paraffin as fuel, but a pull of 4,000lbs. has been obtained under good conditions with petrol as fuel.

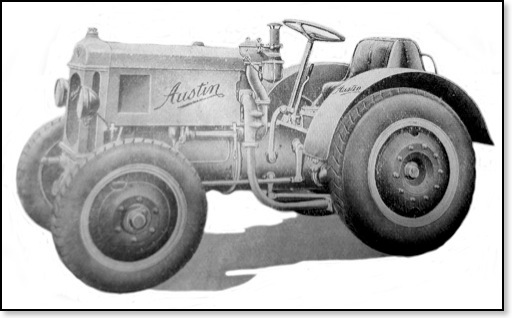

Longbridge Built Tractor

(Inserts show the various tasks it was used for)

Brass Austin Badge

French versions

This shows an early version similar to the UK, although the rear driving wheels have paddles fitted to the outside to get more grip in softer ground.

This one has been converted for mainly road use, towing a trailer etc. Its has headlights and a very comfortable drivers seat, you will also notice that the seat is a double one (back to back) for a passenger, along with a grab handle at the side. It still shows the original Austin Logo on the engine side cover, radiator and rear wing, but the radiator cowl is now more rounded.

This is a later farm version which has now got smaller wheels on the front axle. With the later radiator cowl, but no Austin name on the radiator and the word AUSTIN in bold on the side engine cover.

Scorton Show, North Yorkshire. Sept 2007.

__________________

Austin 12 Tractor ?

This Tractor which is on display in Guernsey was built by the De Garis Brothers Eustance and Fred during at the end of 1943-44 and was taxed in 3rd February 1944. It was built up from various components, as at this time parts were vary scarce. The engine and gearbox were from a Austin 12 coupled to a Vulcan Bus rear axle which had rear wheels from a German truck. The chassis came from an unknown lorry, front axle was a Citroen 12 with front wheels off a Morris 8, cooling was by means of a Citroen radiator. It was used during the occupation for Ploughing, Carting Seaweed etc. Mowing. It could also be made to drive a circular saw by jacking up one rear wheel and putting a belt on the rear wheel.

On Liberation Day 9th May 1945 it towered a trailer to transport people from the country area into the town. It remained in regular use doing various tasks until 1988

____________________________________

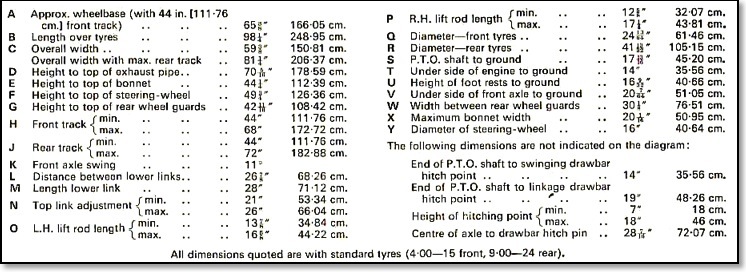

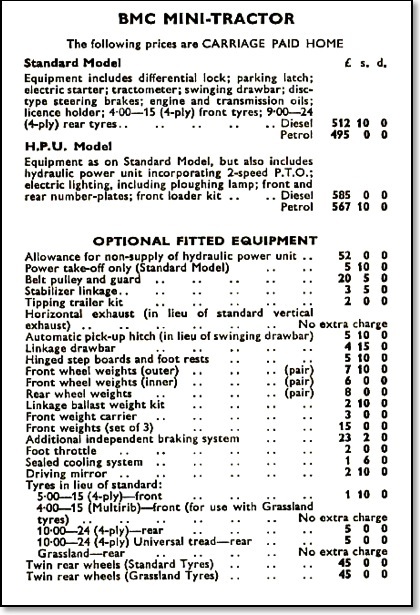

Now the BMC Mini Tractor

Although starting off with a centre gear change, this was changed to the steering column, to bring it in line with the saloon in autumn 1951.

December 1st 1965 saw "MINI" mechanization day. Nuffield tractors introduced their new "Mini" following five years of research and experimentation. The tractor was not well received, it was introduced at a time when tractors were getting larger and in fact the ten was by now classed as small. The Mini measured a mere 8ft 2.25 inches long and 3ft. 8.5 inches from the ground to the bonnet top, it weighed in at 2,098 lbs.

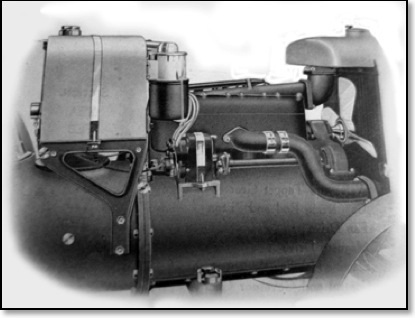

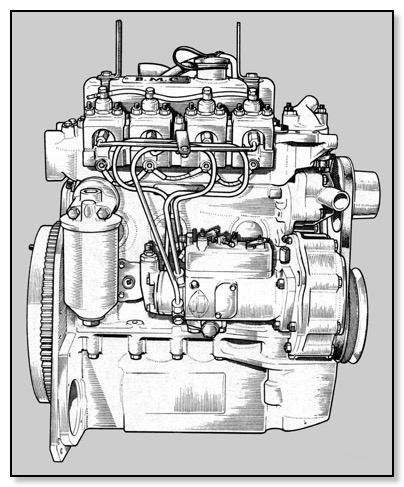

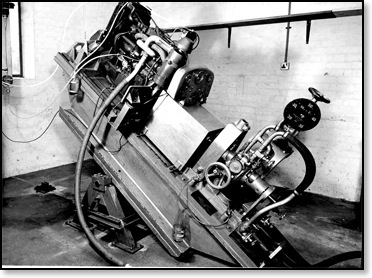

'A' series diesel engine

A large amount of the development was done by "Harry Ferguson Research" of Coventry. The engines were dveloped at Longbridge, the petrol version was a modification of an existing engine, that would produce torque at a lower rev band and across a wider rev range. The diesel version was a completely new engine, with new block, head, crankshaft etc. A diesel engine needs a very high compress ratio to make it work efficiently, this engine had a compress ratio of 23.6 : 1 which was high even by diesel standards. In the development stage the engines were sent to Harry Ferguson Research at Coventry, who installed them in the tractor, and ran them on a rolling road. The picture below shows the engine on test at Longbridge coupled up to a dynamometer. This was a special test rig that was constructed to test that the engine would not be starved of oil when installed in the tractor, and climbing up, or descending a steep incline.

Diesel engine on test

The gearbox was a three reverse nine forward gears, via a high/ medium/ low/ reverse gear lever and a 1st 2nd 3rd gear lever which had a safety start feature. Initial production was a the Adderley Park factory in Birmingham, but was transferred to the new Truck Factory at Bathgate in Scotland. Sales did not reach the levels that made it profitable, so a decision was made to see if a larger engine come improve the sales, so in November 1968 the BMC 1,500 cc 'B' series was installed.

Demonstrating that this 950 cc Tractor could tow a bus

(The Tractor was then donated to Oxfam)

General Data

Engine Type 9T

Number of cylinders . . . . . . 4

Bore . . . . . . . . . . . . . . . . . . . . 2.48 in

Stroke . . . . . . . . . . . . . . . . . . . 3.00 in

Capacity . . . . . . . . . . . . . . . . . 948 cc

Compression ratio . . . . . . . . 22.5 : 1

Max BHP . . . . . . . . . . . . . . . .15 @ 2,500 rpm

Idling speed . . . . . . . . . . . . . . 600 rpm

Maximum light running . . . . . . 2,750 rpm

Maximum speed loaded . . . . . . 2,500 rpm

Torque . . . . . . . . . . . . . . . . . . . 38 lbs/ft at 1,750 rpm