The 'RE-HAB SHOP'

It was in 1943 that the "The Re-Hab Shop" actual became a reality. Around this time 30,000 people were engaged on war work, so the medical staff at Longbridge on average dealt with 1,000 reportable accidents a year. The company thought it needed to devise a scheme that would get the injured workers back at their jobs as quickly as possible.

The idea was not so much a place where injured workers could do light jobs while nature did the rest, but a specially designed rehabilitation unit with machines designed to give operators exercise that would speed the healing process.

After the war their might have been an argument for closing the rehabilitation centre, but accident figures were still high, and the unit, which could accommodate about 40 rehabilitation cases, carried on.

The "Re-Hab. Shop" at Longbridge is synonymous with the latest developments in workers' welfare. It solves the special problem when a worker who returns after a period of illness, and needs to be nursed back into the speed and rhythm of flow-line production.

With better safety methods and a more skilled and stable labour force, the number of factory accidents has been cut by more than half since the war. Now two-thirds of the rehabilitations work is concerned with employees who have not been injured, but simply ill.

AFTER ILLNESS

Any worker who has been ill for more than six weeks, and wished to return to work, is automatically sent to the works doctor for a medical check. It is most important that the person is fit enough to resume their job, if not, the employee is sent to the rehabilitation workshop. The firm's medical officer, Dr. A A White, and the rehabilitation officer, Mr. Norman Share can gauge by practical tests a persons capacity and how best they can be re-introduced to factory working.

Mr Norman Share

The workshop is planned on normal lines to accustom a patient to the factory atmosphere. It turns out standard car components so the person feels they are been useful. Here a patient can step up his working speed over a period of weeks to the maximum considered safe. If it is found they will not be fit enough to return to there former occupation, then training can be started for a new job on the factory floor.

THE INJURED

Meanwhile the original work of the shop for injured and disabled people goes on along similar lines, Every machine can be adapted by special gadgets to suit specific disabilities or provide remedial exercises. In the case of a man with wasted leg muscles, pedal movements are substituted for hand movements. So through out his working day he is restoring strength to the limb by bending and flexing the joints.

With around 260 employees passing through the workshop every year, it's important that the progress of every one is carefully checked. Dr. White estimates the number of cases where a person is not successfully re-employed, is no more than one or two per cent.

FEWER ACCIDENTS

Longbridge works accident figures have been decreasing year on year (Jan 1961), and safety-consciousness is growing in work places throughout the country. What then is our industrial rehabilitation unit doing?

"These days we are greatly concerned with medical cases, which form a very large proportion of the cases which come to us, explained Dr. White the works Senior Medical Officer. Speed and pressure of work today have reached tremendous proportion and people, particularly those who are not in the peak of fitness, can be overtaxed. A man who has been pushing himself beyond his capacity may suffer either physical or nervous breakdown. A foundry worker who has had pneumonia illustrates a special problem in resettlement. In instances such as these retraining in the rehabilitation unit are the first steps on the road back to suitable fresh employment. It is in this recovery period that rehabilitation has its value. To a wage-earner and breadwinner there is little he cherishes more than the right to earn a living."

So having been directed to the rehabilitation unit the majority of cases returning after illness can either go back to their old jobs or be placed immediately in selected employment, with the more serious cases finding understanding and an appreciation of their problems towards the road back to financial security.

This raises the problem what happens when a man or woman leaves the unit? The Rehabilitation Officer, Mr. Norman Share, explained. "I have to keep my ears open for jobs that would suit our people. A man who has been welding on production and was unable to go back, was found a job in the Experiment Department where his skill could be used, and the pace would be easier for him. We rely very much on cooperation from superintendents in letting us, and the Welfare Department know of jobs that would suit rehabilitation cases."

There is reason for Normans Share's enthusiasm in the unit as he was a rehabilitation case himself. "When I had been through the unit, I was offered a job as assistant to the Rehabilitation Officer. Now I am doing the job, and I wouldn't give it up for anything."

A great one for gadgets, Norman has modified many production machines to suit the special needs of the unit.

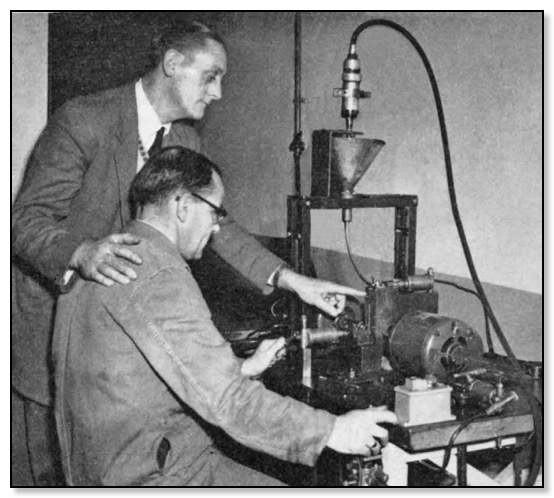

One machine which is Norman special 'baby' is a hand-control automatic machine which drills oil restrictor components.

Mr Norman Share, the Rehabilitation Office, watches as

Rhys Miles operates the oil restrictor machine

"When I saw the job being done in the works, operators picked up the component, held it under the drill, and put it aside. Some of the operators had difficulties with this, and so there were many rejects." Norman's machine thinks for itself, can be hand or foot operated and has such a large output that all the works oil restrictors are now produced from his machine.

Since it opened the unit has dealt with 3,646 people (1961), it will deal with many more in the future.

Issued around 1960

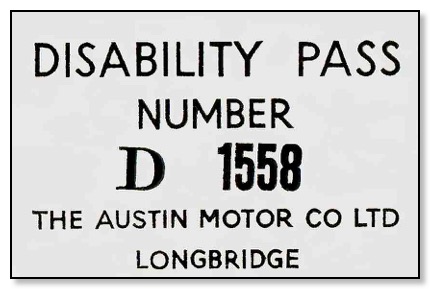

All employees with a disability could obtain a Disability Pass as shown above. This would allow them to leave the factory 5 minutes before their shift ended, so were not caught up in the mad rush.