THE MOKE

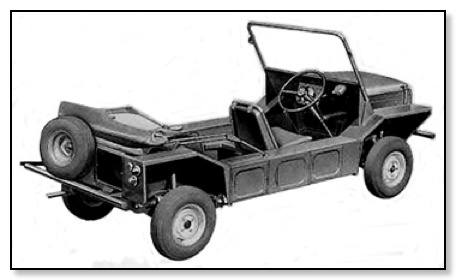

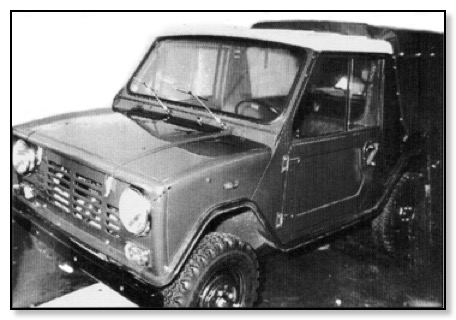

Prototype work started in 1960 with one of the briefs been to produce a vehicle for the Army using Mini components. By using the standard parts of a Mini the only real cost to bring it into production would be the body.You will see from the picture above that the early prototypes had sills that were triangular in section. This was soon changed to a square box section, which gave the body more torsional stiffness. The other benefit was that it allowed the fuel tank to now be housed inside the box section instead of been behind the rear seat. You Also the seats are of the bench type, front and rear. It was thought that the Army would need a small vehicle that could be dropped in by parachute, that would seat four with some space for equipment. The Navy were also approached, and they did show some interest as a means of transport on a aircraft carrier. The main problem was that the ground clearance was poor for any off-road activities so the armed forces lost interest.

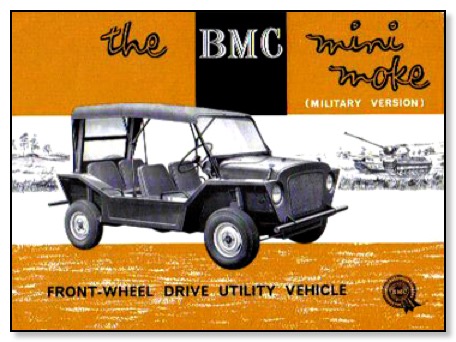

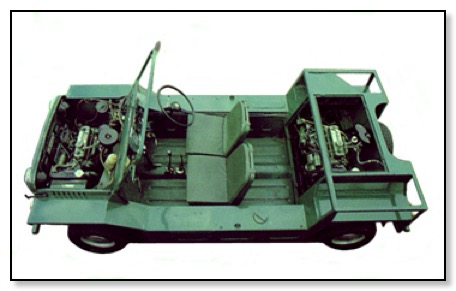

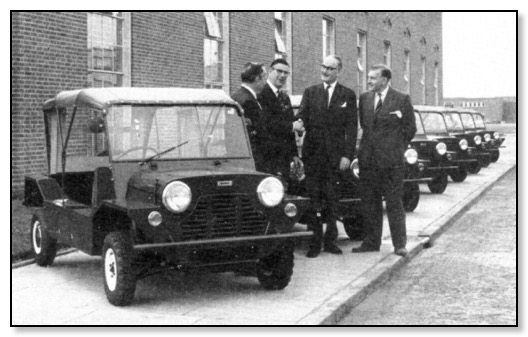

You will see from the military version shown above, compared to the one sold to the general public that the following changes had been made to try and impress the military. There are four seats, the front panel has been modified with the headlamps going into the wings. This gave more room in the engine bay which would help cooling. The grille is now a one piece with a fine mesh to keep out debris.

Why did it get the name Moke, well the dictionary says Donkey, or another definition would be a workhorse.

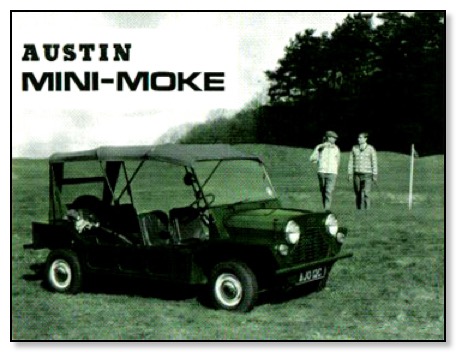

In fact in the American brochures it said the following. "Own a four-passenger donkey! The Austin Mini-Moke is as tough and versatile as its namesake, but not half so obstinate. The rugged transverse-mounted BMC engine combined with front wheel drive, makes it sure-footed on the roughest terrain. Caring a load, caddying around the golf course, or coursing over back roads and beaches, the Austin Mini-Moke is the real 'can do' vehicle. A lot more economical than a donkey, too!"

Moke having a final polish CAB I

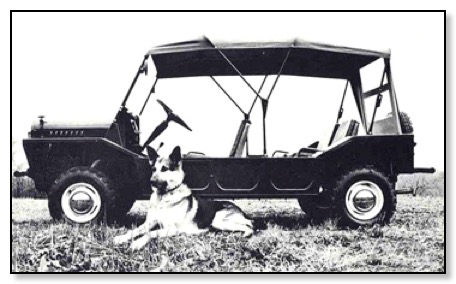

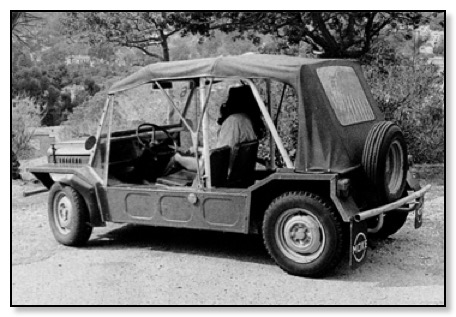

Nice side view but beware of the dog

So would the general public buy it. The company had hoped that the Customs and Excise would class the Moke as a commercial vehicle, as this would mean it would not incur Purchase Tax. But instead it was deemed a car because it could carry passengers and therefore Tax was payable. So it was launched in 1964 at a price of £405 in just one colour Spruce Green. The only standard fitting was a windscreen wiper for the driver, everything else was a option such as passenger seats, grab handles, heater, windscreen washer and a removable canvas top.

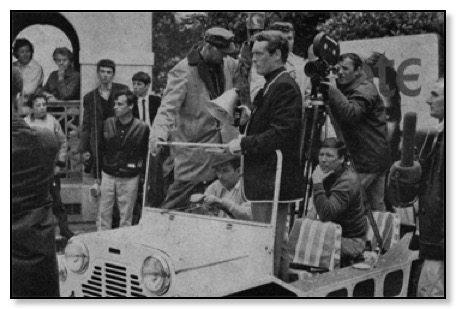

Filming 'The Prisoner'

At first sales were slow but the Moke did attracted attention as a 'cult' vehicle on the back of the Mini but its main media exposure was in the popular television series 'The Prisoner'. In all 14,518 Mokes were produced at Longbridge with about 90% exported mainly to more sunny locations in the world.

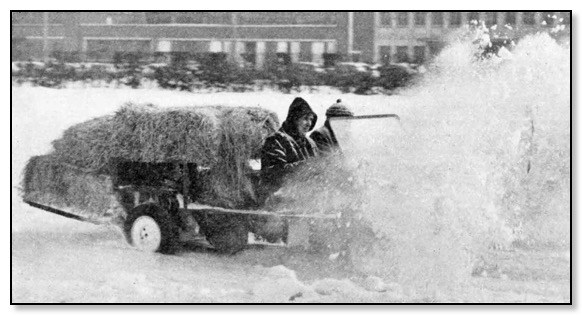

Twin Engined Moke

It was in January 1963 that because of heavy falls of snow, as a way of getting some publicity for the Moke the company decided to make a 4 wheel drive version by simple putting a second engine mounted on a front sub-frame in the back. Originally the gear changes were connect together along with the clutch and throttle pedal. This proved to be a bit of a nightmare as it was very difficult to synchronise both engines and the gear-changes. The solution was solved by putting an automatic power unit in the back, which was not the perfect solution, but as a prototype worked quite well.

Twin Engine Moke on the CAB car-park

Driven by Mr W J Daniels, 'A' Group Design Projects Superintendent

Mr B Mackenzie 'A' Group Designs

Press Statement June 1964

US Army Testing BMC Moke

The United States Army is carrying out trials with two British Motor Corporation vehicles derived from the design of the mini-car, the BMC announced yesterday. One is the Mini-Moke and the other the Twin-Moke a twin-engined version. Left-hand drive prototypes of each are undergoing study and evaluation by the United States Army Tank Automotive Centre.

The single-engined Moke is a general, purpose vehicle, built by BMC for possible military use. Powered by an 850 cc engine mounted transversely and driving the front wheels, it is likely to go into production this year.

Originally fitted with two 850 c.c. Mini engines. the Twin-Moke is a four wheel drive version, first produced experimentally by Mr. Alet Issigonis, technical director of BMC and Mr. George Harriman the corporations chairman during the severe 1962-63 winter.

In January last year, at Longbridge, I drove the first double-engined Moke, which proved capable of astonishing performance and road holding in deep snow and mud. In its latest form the Twin-Moke is powered by two 1,100 cc. BMC engines, fitted tranversely front and rear and driving each pair of wheels, with twin, linked gear levers. The open-bodied vehicle can carry four passengers or a heavy payload. No vehicle of this type have yet been sold to the United States Army, but BMC say that they are undergoing field tests"all kinds of extensive field tests".

One of the Mokes on test in the US by the Army, the main reasons why an order did not materialise was because of the lack of ground clearance.

A Twin Engine (1100cc) Moke sent to America for evaluation by the US Army

_____________________

In 1967 a MkII was announced which incorporated changes that had been introduced in the Mini. But you did get a passenger wiper as standard now, along with a choice of two body colours Spruce Green or Snowberry White. Another try was made to interest the Navy, but it came to nothing.

Ready for Take Off 1968

. . . . . . . . . . . . .Graham Robinson

Army Moke

Date when launched August 1964, production ceased in 1968. Production was then transferred to Australia and then in 1981 to Portugal.

Total produced in UK 14,518 of these 1,467 were for Home sales and 13,051 for Export.

Total produced world wide about 30,000

Engine

848 cc 34 bhp at 5,500 rpm Max torque 44 lbs/ft at 2,900 rpm

Australia and Portugal builds

1275 cc 58 bhp at 5,250 rpm Max torque 69 lbs/ft at 3,000 rpm

Length 10ft 0ins Width 4ft 3.5ins Height 4ft 8ins

Wheelbase 6ft 8ins Track front 3ft 11.4ins rear 3ft 9.8ins

Price ex Works at launch was £475

Early version with both Manual Gearboxes

Rear Engine Manual Gearbox

Australia Build

Moke production started in Australia in 1966 using CKD panels from the UK. Unlike the UK it used the 998cc engine and 10" wheels. In 1968 production was totally sourced locally, and in April that year the 13" wheels were introduced. This increased ground clearance making them more practical for gentle off-road or beach use. Between 1969 and 1980 the Australian Military placed an order for more than 250 Mokes.

An additional version called the Californian, using a 1275cc engine were built between 1971-1973, with around 1000 been produced. This body was noticeable different to the standard model with rear fuel tank and side lights for export to the US Virgin Islands.

In 1977 the Californian name was reintroduced along with improved seats, trim and wheels available. A pick-up version was announced in 1975 as a drop side type with a cloth top over the cab area. This was soon followed in 1978 with the 1275cc engine and disc brakes available on some Californian models.

1978 saw a 4x4 prototype being built using a second pinion driven off the rear of the crown wheel, unlike the UK prototypes, this had only one engine.

To improve the durability of the body it was now galvanised along with a side fill fuel tank taking up the whole of the side-box to meet certain Australian Design Rules in 1980.

June 1982 saw production ending in Australia.

Australia total production was 34,704

Portuguese Moke 'Californian'

When production ceased in 1981 British Leyland transfer production yet again, this time to their subsidiary in Portugal where the "Californian" version which had been developed in Australia continued till 1991 having built 8,500 in this 10 year period. At this time British Leyland had seen many changes and was now called The Rover Group. The rights to the Moke were sold in 1991 to Cagiva a motorcycle manufacturer in Italy who decided to continue to make the Moke in Portugal. One of the changes they made, was to standardise on the then current Mini parts from the UK, this meant they were fitted with 12 inch wheels A decision was made in 1993 to transfer production to Italy, in the end production was never restarted. So in that two year period 1,500 were produced, this made total number of Moke's produced in Portugal to 10,000 units.

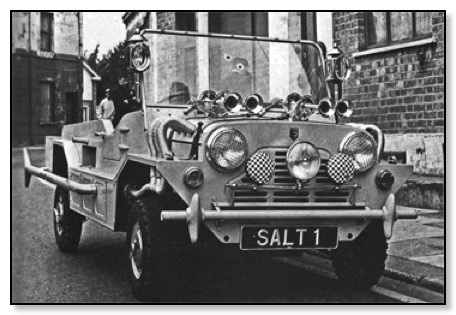

This was a standard Moke with body modifications for a film called Salt and Pepper.

Different front treatment now badged BMC

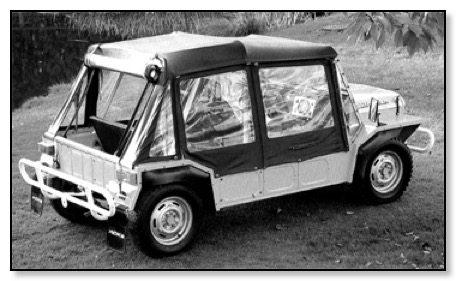

This left-hand 850cc engine Moke was imported into the UK. It is fitted with a Barton hard-top

In the 1960s about forty Mokes were imported into the Catalia Island California which could be hired to get round the island. By the mid 1990s they had all been replaced by golf carts

How to customise your Moke

Taking delivery Devon County Fire Brigade

Army Conversion

_________________________________________________

And along came the ANT (ADO19)

Mock-up of the Ant (1964)

Early Prototype Ant (1966)

Was this going to be the MKII Look

Fully Engineered Prototype

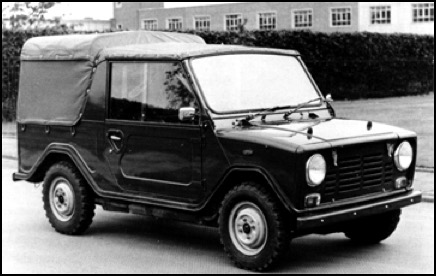

It was in 1964 that work started on the Ant, designed by Sir Alec Issigonis for the then BMC. Sir Alex Issigonis had already applied for various patents in 1962 which mainly covered the transmission aspects of the design. Conceived for two markets, one being for military use as the Moke had been rejected by the Army mainly because of its ground clearance and only two wheel drive. One feature that the Army had asked for was that the passengers seat would fold-down flat, so allowing a stretcher to be carried It was also thought that there could be a market for a small Land Rover type vehicle. So the Ant which was based on the 1100 platform was only 3ins longer than the Mini at 10ft 3ins. If this vehicle had reached the market place would it have been the start of a new vehicle that would have become a cult like the Mini.

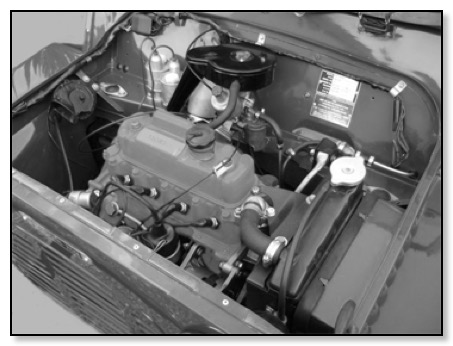

Under Bonnet

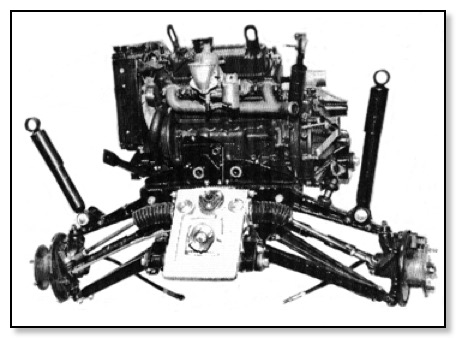

Power was from the 1098 cc A series engine, but later this was changed to the 1275 cc version. Althought the larger engine gave only 2 hp more, the torque increased from 61 lbs at 2,000 rpm to 69 lbs at 3,000 rpm. The engine is tilled backwards, as can be seen from the above picture. (Note the rocker filler cap). The whole engine and four speed gearbox along with a transfer box would have compromised the ground clearance if it had not been inclined backwards. It had high and low ratios and the drive to the rear wheels could be disengaged if only 2 wheel traction was needed as this would save on fuel and also gave the vehicle a higher speed.

Power Unit

One interesting point of the design, was that the steering rack had a centre pinion so could be used for both right hand and left hand versions. The front suspension, by torsion bars, with the one end fixed on to a cradle attached to the transmission housing. So in affect the whole engine, transmission and front suspension could be removed as one unit, The rear suspension used a single torsion bar that was held in the middle and the ends fixed to each wheel unit.

Braking was by means of 8 inch discs at the front and drum at the rear. Ride was fairly neutral with minimum roll or pitch. which by all accounts proved fine.

It had front disc brakes with drum on the rear and 12in wheels. So this unique vehicle became the world's first 4 x 4 trasverse-engined that was light and compact making it suitable for airborne operations.

Some experimental prototypes were built, and after evaluating the test results it was decided to move to the next stage. This was to build 30 pre-production fully engineered prototypes, whilst this was happening a decision was made to order the tooling so as to prepare for production with the bodies to be made by Nuffield Metal Products in Birmingham.

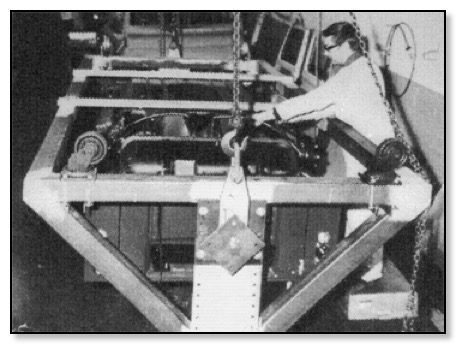

The 30 pre-production build was to be done by Methods Proving Department at Adderley Park Birmingham. Shown below is the cradle that was constructed, the body was bolted to the cradle which then allowed the body to be rotated, which made the fitting of components easier.

Finished Ant

The various prototypes were then dispatched round the world for evaluation. Early in 1968 three prototype vehicles were sent by BMC to Australia and New Zealand for evaluation by the Armed Forces. One stayed in Australia for reasons unknown, and the other two came to New Zealand. A Soft-top model went to the Auckland Austin dealer Seabrook Fowlds, this was then loaned to the Kaingaroa Logging Company which was located at Rotorua, North Island. This evaluation appears to have shown that there was a weakness with the transmission.

The other a hard-top model went to P H Vickery, the Austin agents of Invercargill. The two examples in New Zealand were sold to private buyers. The white coloured Invercargill vehicle was purchased by a local farmer Alfred Walmsley and used on Stewart Island. It was later purchased and now owned by Geoff Sneddon of Dunedin.

Then came the merge between BMC and Leyland who owned Land Rover, so the Ant was looked at by the new management in 1968 as been to close a competitor to the Land Rover range so the project was cancelled before production got underway and most of the vehicles were broken up. According to the Heritage Motor Centre at Gaydon there is only two in the UK, one in the museum and one private owner whose vehicle I have photographed, with five others around the world.

As with many concepts from the design studios of BMC at Longbridge in the 1960s, they were way ahead of their time. It makes me sad that the management did not have the vision to bring these concepts into production, the Ant been one such example.

Final Pre-Production Version

Note the change to the canvas roof which gave more headroom

Main measurements

Length 10ft 3ins Width 4ft 6ins

Wheel Base 6ft 5.5ins Track 3ft 11.3ins Turning circle 33ft 6ins

Hard Top Conversion