Longbridge Tour

An account of a visit to the Longbridge Works in 1929

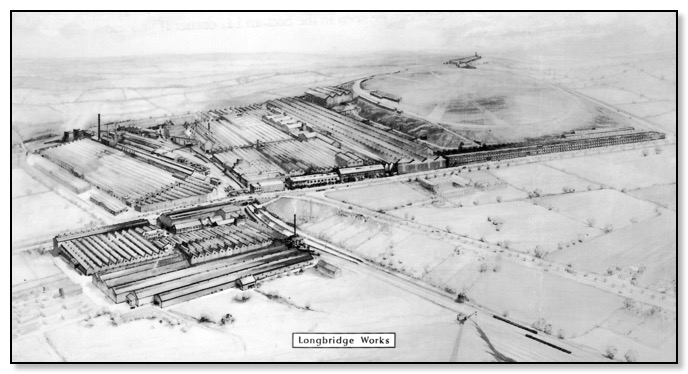

The Longbridge works of the Austin Motor Company is situated seven miles south of Birmingham on the main road that runs from the city centre to Worcester. It original occupied 2.5 acres in 1905 when it was out in the country, but now it has grown to 220 acres. and can best described as now semi rural

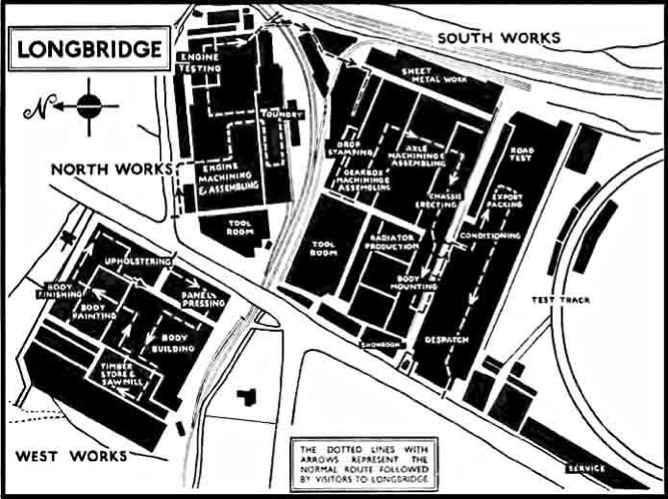

Physically the works are made up of three sections. One of these, that is now called West Works was built in the war and was devoted then to the production of munitions, turning out 8,000,000 shells, various sizes up to 9.2in along with many 4.5in howitzers. Enormous quantities of night tracers, percussion tubes, burster cases, and shrapnel heads, and thousands of aeroplane engines, electric generating sets, and Lewis-carts.

The other two sections, on the other side of the road, are known as the North and South Works, the later is flanked on the South by a large test track and sports ground, includes the little nucleus from which the great factory has grown. The Halesowen Railway, which gives communication with the great Western system, separates these two sections, and they are bounded on the East by the main Derby-to-Bristol line of the London Midland and Scottish Railway, just where it emerged from the Cofton Tunnel, which has recently been demolished and converted into an open cutting.

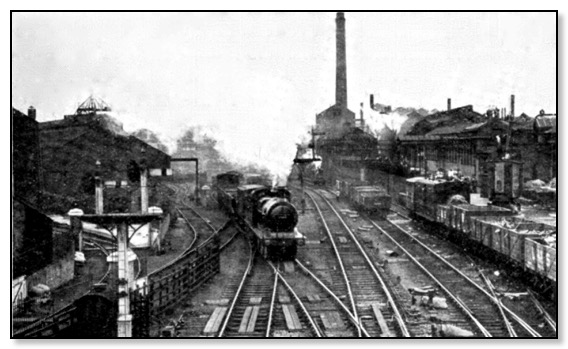

Railway Facilities

The railway facilities are thus excellent, and they are turned to good advantage by means of connecting sidings with an aggregate length of seven miles, which enabled trucks to reach and be dispatched from every part of the works. every year these sidings receive over 120,000 tons of material, and 45,000 tons of coal, coke, and oil fuel are brought in, the works requiring the services of eight goods trains a day. the corresponding output is, in round numbers, 200 cars a day, most of which go away by road, but, some by rail, securely packed complete in special wooden boxes, and some in the form of chassis parts for reassembly at their destination.

View from the Railway Bridge

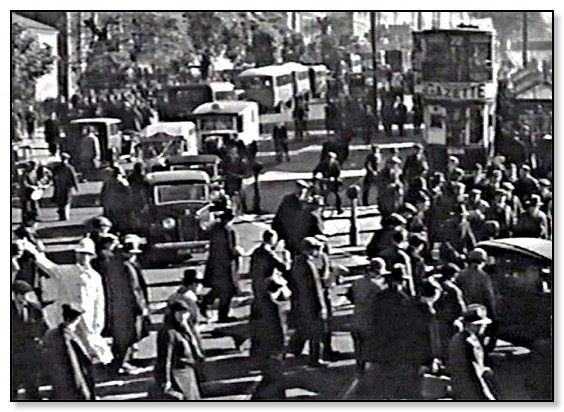

How great are the advances that have been made in methods of production is indicated by the fact that in 1906 the manufacture of 120 cars required 270 workers, whereas to-day over 60,0000 a year are turned out by rather more than 12,000 employees. The dispersal of this crowd of men and women, when work stops at half past five in the afternoon, is a remarkable sight. They travel by special trains, with the works have their own private passenger station or halt – tramcars, motor- omnibuses, bicycles and various nondescript vehicles, and in 20 minutes or so they have disappeared, leaving behind them only a few men in the foundry, where operations cannot be entirely discontinued, and a night costing staff which gets out the cost of manufacture from day to day.

Looking up the Lickey Road

At presents the Longbridge works are producing five models – Twenty and a Light Sixteen with six cylinders, and a Twenty and a Light Sixteen with cylinders, and a Twenty, a Twelve, and the famous Seven with four. These are the Treasury or RAC ratings, but in fact all the models when their engines are running at 2,000 RPM, develop at least twice their nominal power on the brake, except the Seven, which at 2,400 RPM gives 10.5 break horse power. Incidentally it may be mentioned that this little car is an old love of the Austin Company; they first introduced it in 1910, and though, with its single-cylinder engine, it was very different from what it is now, it even then had three forward speeds and reverse, as it has today.

Manufacturing Methods

While these five models offer a range that meets all ordinary requirements they permit the realization of the economy that arises from continuous production on a large scale, and avoid the expense which has sometimes proved the downfall of makers essayed the undue multiplication of patterns. It must also be emphasized that these cars, chassis and bodies alike are really and truly manufactured at Longbridge. The Austin Company are not mere assemblers of purchased parts, and though some components, such as tyres, have, of course, to be bought in, all the processes required to convert the raw material into finished cars are, generally speaking, carried out within their own works.

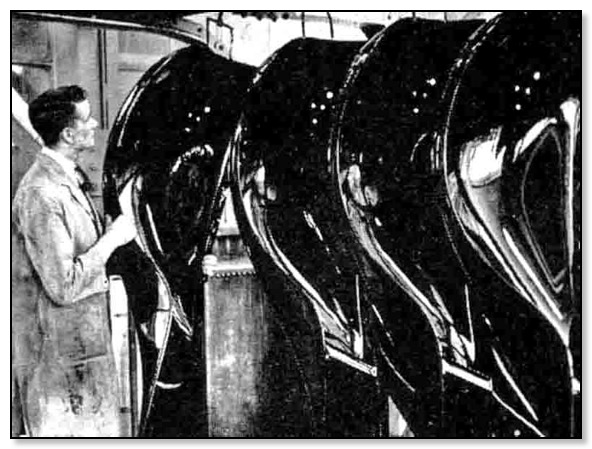

Pressing Body Panels

Some of the initial stages of this conversion are carried out with cold metal, but most with hot. Cold working is to be seen in the light and heavy press shops, situated in the South Works alongside the LMS railway, which contains presses of all sizes and capacities up to the huge 500 ton Bliss double-action toggle press, which was the first tool of its kind to be used in this country. By passage through these machines sheets of metal are formed into a great variety of parts, such as mud-wings, shields, scuttles, tanks, panels both with and without window spaces, and many other smaller objects. For some articles two or three operations are required, but in any case a few seconds suffice for work which took several workers, when formerly it was done by hand. More than that, the margin of error of the machine is very small, and in respect of accuracy the product is much superior.

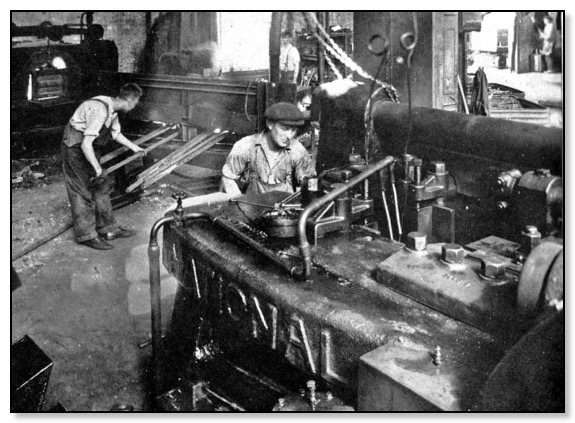

Metal Work

Drop - Forging

In the stamping shop work is done with white hot metal. This shop is also in the South Works, and adjacent to it is the steel stores, containing stocks of many kinds of steel, each having its own distinguishing mark and colour painted upon it. Alongside there is a shop in which the rough steel is cut into suitable sizes and lengths. The stamping process is applied to the production of many diverse objects, ranging from an autovac strap end weighing half an ounce to a flywheel having a weight of 1.5 cwt. Like cold pressing, hot stamping involves the use of intricate and costly dies which have to be fashioned with the greatest accuracy, these are all made in a special department known as the tool room. This is in fact a works inside a works, and in view of its vital importance it may fairly be called the heart of the whole establishment. The manufacture of dies is only a part of its duties, and in addition it is responsible for designing and making tools that are needed to meet the special requirements of the company in the machine shops, as well as for making and keeping in order the jigs and fixtures which ensure rapidity and accuracy of workmanship.

Of two other departments which lie close to the stamping shop, one is the pickling shop, where the stampings are immersed in chemical baths to clear and free them from scale; and the other is the heat treatment and hardening shop. The surfaces of gears and similar parts have to be hardened in order to enable them to resist wear, the operation being conducted in furnaces heated by means of vaporized oil or of town gas supplied by the Birmingham Corporation. The purpose of heat treatment, for which producer gas is employed, is to coax the steel, by submitting it to appropriate temperatures, into the condition in which it is best able to bear the stresses put upon it during use.

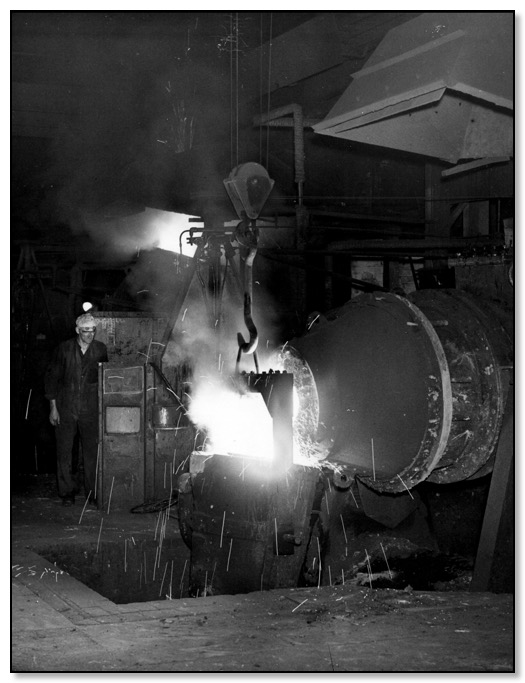

Foundry

It is necessary to cross over into the North Works to reach the foundry, which is concerned entire with molten metal, here steel, cast iron, and aluminium are worked. Each week around 35,000 castings which representing a weight of 100 tons are produced by oil-fired Stocks converters. The casting produced include the largest parts of the engine, such as the cylinder, which whether four or six in number, consist of a single monobloc casting and the aluminium crankcase. The equipment includes modern hydraulic moulding machines, and the sand-mixing and conveying machinery is the best that money can buy. Sand has to be of special quality so as to produce castings up to the standard insisted upon by the Austin Company. Adjacent to the foundry is a well equipped pattern shop, where both wooded and metal patterns are constructed. To the east of it stands the main power house, which produces 4,500kw of power from three turbo-generators, sometimes this is supplemented from the mains when needed.

The Machine Shops

The foundry completes the list of departments in which the use of heat is the dominant factor, and in the various machine shops to which the rough shapes that have been produced from raw metal are next taken, where the operations are performed cold. Such heat as there is generated by the action of the machines themselves and is a nuisance rather than a help, and in most cases special measures have to be taken to remove the swarf. To prevent the item been machined from getting too hot, which could effect its accuracy, the cutting edges of the tools are flooded with a liquid coolant. The operations are of the most diverse character and are performed on hundreds of machines, but they all resolve themselves into the removal of metal, by cutting, milling, drilling, boring, grinding or allied processes.

___

Crankshafts Machining

The machining of the different parts is concentrated in different shops or portions of shops. No 1 machine shop, for example is devoted to the production of front and rear axles, and here the various details are machined and put together as they move forward step by step, until at the end of the line they emerge as finished units, ready to be incorporated in the chassis after passing the standard test . In a still larger shop allocated to engines and gearboxes the same system is followed. The engine castings have boxes made truly round and smooth, their heads receive the attentions of multiple drill, which piece them with holes by the dozen simultaneously, and the two put together are subject to hydraulic pressure to prove their soundness.

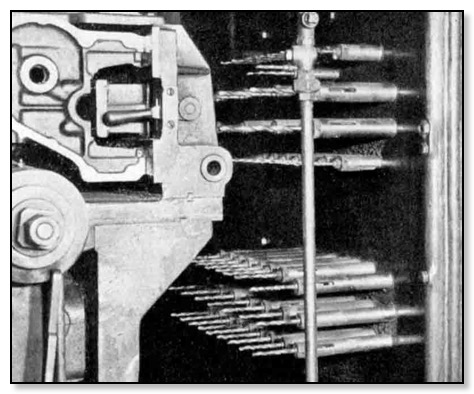

Multi-Spindle Drilling Machine

Elsewhere a line of crankshafts may be seen in different stages of finish, but all moving towards a machine where the trueness of their balance is ascertained. here the operator is able to ascertain whether a slight excess of metal, which would be detrimental to the smooth running of the engine, has been left on any of the throws; if a defect of this kind is discovered it is rectified before the shaft is passed for service. Meanwhile other engine components are being made in other parts of the shop, and finally they are brought together and fitted in place one by one as the engine moves along the assembly line, until at the end it is a finished unit ready for its bench test.

Crankshaft Balancing

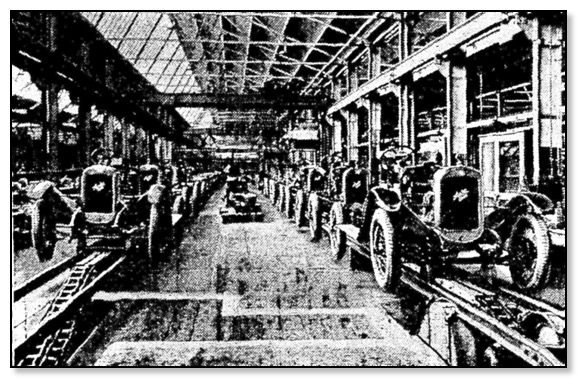

Chassis Assembly

In assembling the chassis the same principle is followed. By mechanical conveyors of various kinds with some underground, overhead, or at ground level. The different component units are brought to the points of assembly ready to the hand of the erector. Starting life at one end of an assembly line as a steel frame, the infant chassis is moved on step by step by the mechanically driven track on which it is mounted, and at each step the parts axles, wheels (with their tyres already fitted), transmission, gear-box, engine, dashboard, and all the rest of them – come successively into place and mechanics perform the operations necessary to fix them. By the time the chassis reaches the other end of the line it is fully grown up, and is driven off under its own power for a running test before being taken to receive its body.

Chassis Assembly Line

The bodies of the Sevens are made in a shop close to that in which the chassis are assembled, and are also mounded there. The larger cars are finished in a huge new shop, nearly a quarter of a mile long, which stands to the south of South Works, but bodies are made in west Works. Here an astonishing number of trades are represented. There are large stocks of skins of various colours, which have to be cut up to the best advantage to form the leather coverings of cushions. The preparations of the upholstery and the trimmings gives occupation to a small army of workers, many of them women; cutting machines deal with thousands of yards of carpet and other materials daily; and ingenious sewing-machines stitch bands on the fabrics used to line the roofs in such away that no seam is visible when the material is attached in position.

Body Building

Though wood is used to a smaller extent than formerly in the construction of bodies, there is a large sawmill and workshop, the atmosphere of which is kept free from dust with remarkable success. The foundation of a body now consists of a steel framework, the members of which, are each designed to give the necessary strength where it is required and specially stiffened at the points where the severest stresses are imposed, are firmly riveted or welded together, and the rigidity and resistance to distortion of the structure are enhanced by aluminium sheets or panels fastened upon it. These metal panels lend themselves well to the application of the new cellulose lacquers, and the end result of the combination is regarded as a definite advance upon wood construction with paint and varnish finish. In completing the bodies the same progressive principle is adopted as in assembling the chassis, some operation being performed or some part added at each point as the move along a trackway.

Wings Been Enamelled

So far as production methods are concerned the motto of the Austin works might well be “Make and Use” In general, components and parts are not made for store, but are used as quickly as they are made. Output in the foundry, machine shops, and other department is balanced to keep even pace with consumption in the assembly bays; and while there is no delay owing to lack of necessary constituents, there is no accumulation of manufactured material lying unused and representing idle capital.