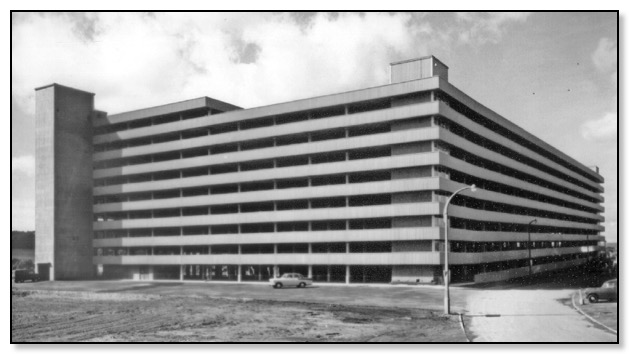

Multi-Storey Car Park

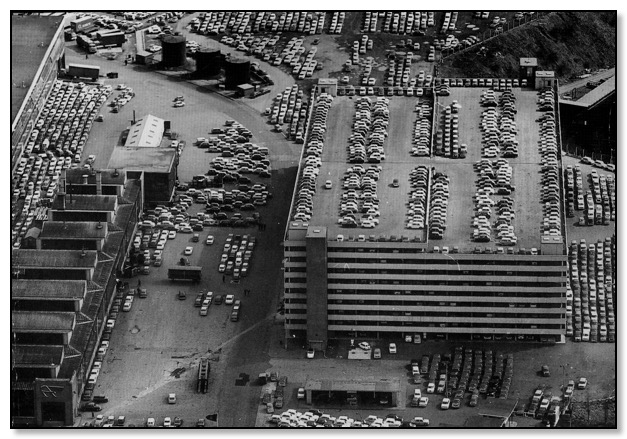

With production rising it was necessary at Longbridge to make use of the available land more economically. A big portion of the land by 'Q' gate was used for the storage and dispatching of vehicles. With CAB 2 coming on stream with the 1100 production, the problem could only get worse. So it was decided that a multi-storey car park was the only answer.

The space for car storage was required to provide a buffer between the production lines and Dealer storage and selling point. This was against a production rate of around 7000 cars a week in the Sixties. The main reasons for the buffer storage were: To store cars that had been built less some component, usually due to an industrial dispute in the works or at a supplier company; any excessive rectification caused by a quality problem; inability to remove vehicles from Longbridge due to transport problems; the holding back of new model introductions; the need to batch despatch certain vehicles for particular markets. Most importantly was an attempt to try to cope with the mad registration change of once a year, the Multi provided the opportunity to safeguard and iron out to some extent the fluctuations in Production requirements and to avoid the lay-offs that could occur each year.

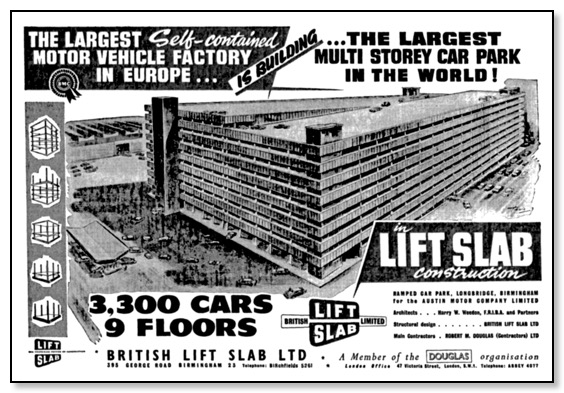

The company needed it to be built in a very short space of time and so the contract was given to Douglas (Contractors) of Birmingham, using a new building process developed by the South West Research Institute in Texas USA, which was very suited to making multi-storey car parks. The system was called the Lift Slab technique which was introduced in 1950 in the United States.

The Lift Slab Construction

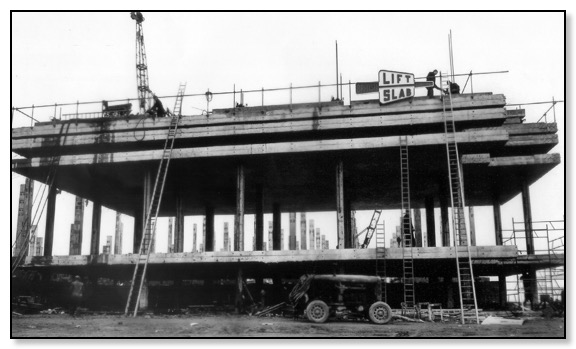

With this system it eliminated the needs for formwork, scaffolding and mechanical hoists as the building goes higher and higher. The first stage in the construction is the building of the pillars initially not to the final height. As the floors are cast one on top of another at ground level a solution is sprayed on them to prevent them sticking together, this solution or ‘filling’, being broken when the stacked slabs are lifted usually two at a time.

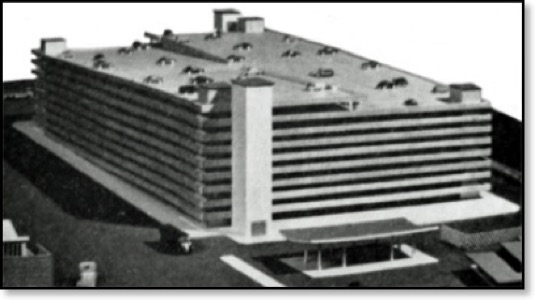

At the top of every pillars is a jack which has a lifting capacity of 65 tons., the total weight of two floors in this build was 700 tons. The first lift was made on in Mid February. It measured 384ft long by 204ft wide. Although I called it a jacking process, by means of hydraulic units at the top of each column lift the slabs, their weight being taken by threaded rods. When the worlds largest car park is complete it will have eight floors along with a roof park, that will be able to houses 3,300 vehicles, and will have cost £550,000.

The top floor being 72 feet above ground and 722 feet above sea-level. High-tensile steel bars play an essential part in the strengthening of the concrete columns and floors and it is estimated that the bars being used to reinforce the structure, if placed end to end, would stretch from Longbridge to Aberdeen. The columns up which the slabs have been slowly creeping and are also cast on site, if laid end to end they would have reached to Cadbury’s at Bournville.

The Car Park soon adopted the name which everyone knew it by – “The Multi”.

Initially it worked quite well but keeping control over what entered and what left the Multi was a nightmare, and gave the operators quite a headache. Over the years it gave Longbridge a degree of flexibility that was very useful but in reality it was not big enough, or easy to control. The only time it ever got near to empty was during the 2 week summer shutdowns or during prolonged production downtimes due to disputes. Inevitably it would soon fill back up when production restarted.

However, there was always the odd vehicle that no one new anything about, such as the car with the wrong colour, engine, trim colour and no build card or vin number, which was eventually modified and sold of to an employee at a discount, or the batch of cars built to an export specification that had suddenly changed and could not be sold anywhere else.

The Multi was a large structure in an exposed position with sides that wind, rain and snow could penetrate; it appeared to almost have its own climate, if you went up to the upper floors in the winter it felt as if you were in Siberia being very cold, windy and damp, even in the summer it felt cold and depressing. It was not exactly the best place to store new cars for any length of time, any vulnerable part on the vehicle would soon succumb to corrosion or tarnishing but it was better than storing in fields as most car companies did.

Gradually over the years quality improved, basic build controls became efficient, disputes less, and in conjunction with the realisation that a car in the Multi was tying up valuable capital.

On the eastern end was a steel lattice mast which had various VHF/UHF communications antenna used for internal radio communication and a microwave dish which was part of the first public company microwave telephone system set up in the UK. It initially linked Longbridge to Cowley. The mast also had an Amateur Radio Repeater and antenna which covered the South Birmingham and North Worcestershire areas.

One strange side issue of its construction was its unfortunate ability to block out a number of local peoples’ television reception, it was kept very quiet and the problems were resolved by a few modifications to the peoples’ antenna.

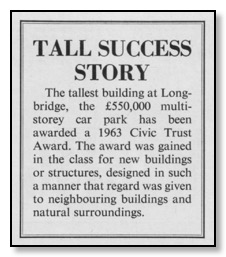

The Multi Won the Civic Trust Award for innovative buildings in 1963. I believe that the quoted life for the Multi was only 40 years, which it achieved, some concrete and steel breakdown was evident and it was at the end of its useful life when in 2002 it was demolished.

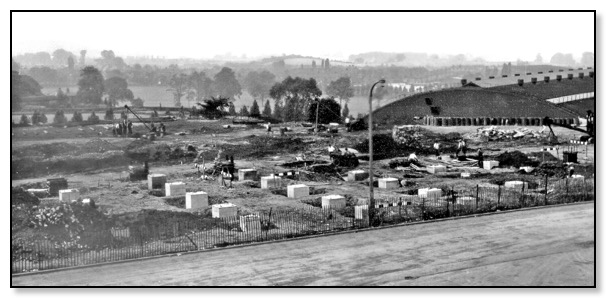

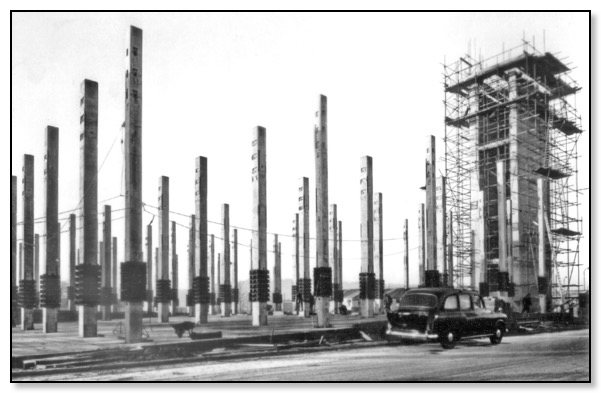

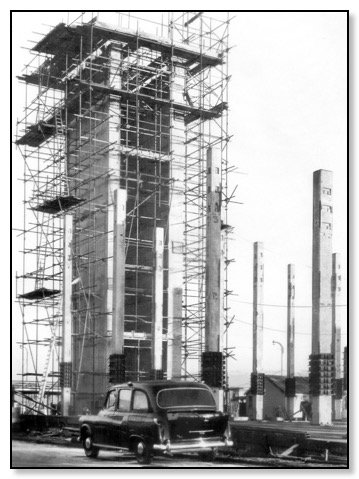

Various stages of construction

Foundations go in for the main pillars (Note how low the Flight Shed looks)

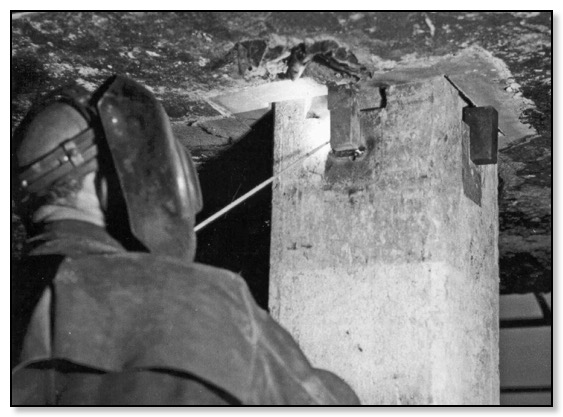

As each floor is jacked up to the correct level, then it has to be fixed at this point. This is done by inserting steel box wedges, that are then welded in position.

This building ceased to be used in the 1990s, so was demolished in 2002.

View from the road by 'Q' gate