Hayes Auto Transmission

It all began in America when a Frank Anderson Hayes who lived in Middletown, Monmouth, New Jersey USA. began experimenting with a method of transmitting power at a variable speed, but at the maximum torque. He filed no less than six patents in America under the heading Hayes Variable Speed Power Transmission on the 7 May 1929, and then in the UK on the 2 September 1929. Two years later he again applied for further Patents, this time under the heading, Improvements in or Relating to Variable Speed Power Transmission.

I would appear that Frank Hayes, who came over to England in the late 1920s and through a chance meeting with Captain J.L. Cloudsley, who owned his own engineering company at 5, Chancery Lane, London. Captain Cloudsley suggested that Hayes should make contact with Herbert Austin. A meeting was set up between the three parties, when it was agreed to work together to improve the system, with Hayes building the gearboxes in America and supplying them to Cloudsley Engineering, who would act as an agent for the UK. Although the system was covered by USA patents, It was agreed that the transmission need to be covered by a UK patent, so in June 1925 GB254341 was taken by Cloudsley Engineering Co Ltd. There followed many more patents after, with some been because of the experimental work carried out with Herbert Austin

29--- June---- 1925-------254341

- 7--- May-----1929------ 343988 & 344061-66

28----April----1932----- -398582

- 5----Sept---- 1933------ 424652

- 2----Dec-----1933------ 431199

-l0-- - Jan----- 1934------ 436363

-24 -- Jan------1935------ 432275

After the supplying various prototypes boxes for evaluation at Longbridge, The Austin Motor Co. Ltd signed an agreement with FA Hayes & Cloudsley Engineering Co. Ltd. for them to supply the automatic gearboxes. I am sure that the agreement that Austin signed up to would have stipulated a minimum quantity. It was not until late 1933 that the transmissions became an optional on the Westminster and the York saloon with either the 16hp or 18hp engines.

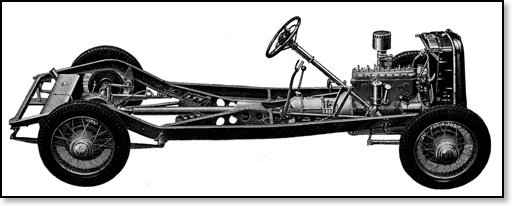

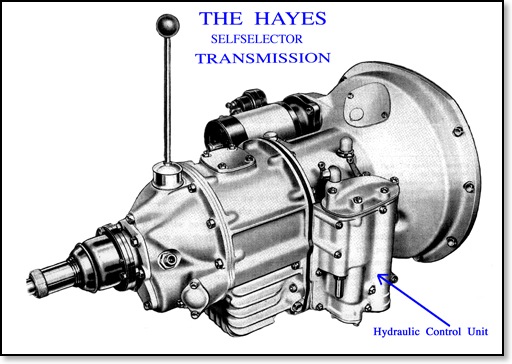

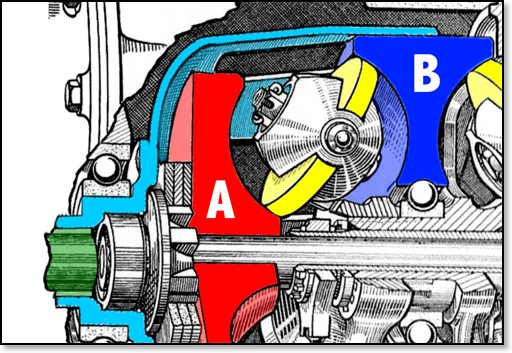

Hayes transmission installation

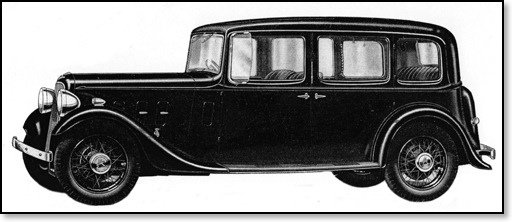

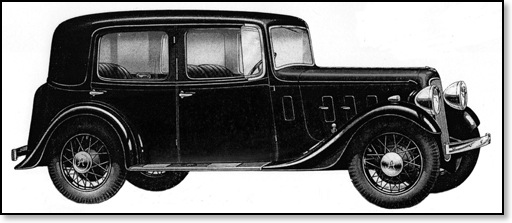

York Saloon

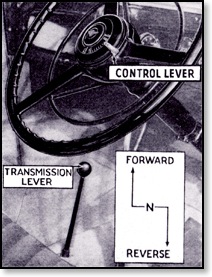

It appears that the optional Hayes gearbox was first available on the York saloon at around November 1933. Publicity at that time stated that the Hayes box would cost an extra £40. The early production models had two levers on the steering column which would allow the driver to modify how the transmission would operate. This proved in practise to be a problem, as the driver was confused which position the two leavers should be in to optimise the transmission for the type of road condition. So this arrangement was changed for the 1935 model year, in that it now only had one lever.

This lever had a "Cold" starting position, the next position went from Low to High, with the last position been used if you were driving in traffic.

Westminster Saloon

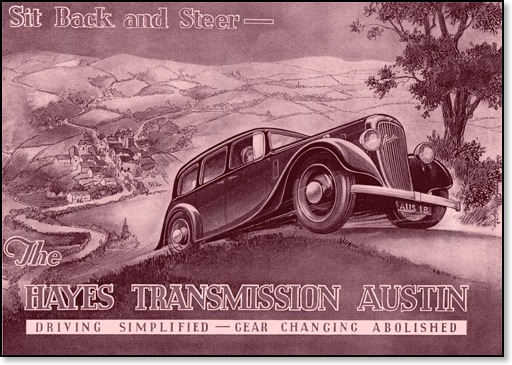

With the MKII version along came an increase of £10 for the transmission at £50. This made a York ex-works price including the Hayes transmission to £368 for the 16 hp version and £378 for the 18 hp. The Westminster was more expensive at £388 for 16 hp and £398 for the 18 hp. With the revised box now available Austin spent a great deal of money on advertising.

This is how the company portrayed the Hayes transmission.

The advent of the Hayes Self-selector Transmission is a development of the first importance in the history of the motor car, and for the following reasons.

Dependability

It is not an experiment in a new sphere of dynamics. It is a new application of an old and tried principle, and, as such, the proved product of years of intensive research and experiment.

Simplification

It is a simplification, not a complication of the transmission. It dispenses with all gears (except to give reverse) and all clutch operations (except when starting and stopping). There is no noise; the drive is practically silent.

Infinitely Variable

It provides infinite variable engine-speed to road-wheel-speed ratios within the limits of its range. There are no gaps in the ratios. The variation is continuous and is fully automatic, yet the driver can, at will, modify its action to give instantly any special road performance desired.

An Entirely New Sensation

It brings to motoring an entirely new sensation of control, a delightful mastery over all road conditions.

Sadly the public did not take to it, even though the Press and people who owned one, spoke highly.

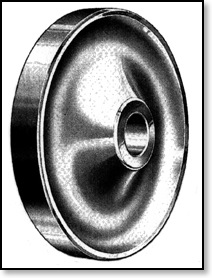

Only about fifty were sold, there were probable two main reasons for poor sales. First it was not strictly a fully automatic transmission as you still had a clutch when starting off and had to us it to disengaged when coming to a halt. The extra cost add nearly 16% to the normal price of the car, this was too higher a price to pay. The actual cost of producing the box was high because of the tight tolerances in the machining and grinding the discs and rollers. The Toroidal cones, which were at the heart of the transmission and manufactured to very tight tolerances by Ransome & Marles Bearing Co Ltd of England.

If a fault occurred in the transmission, the agents were not allowed to service the unit, and a replacement box would be fitted at a cost of £50. The units were assembled at Longbridge, from kits which were probable supplied by Cloudsley Engineering Co. Ltd for the main castings etc. According to an apprentice at the time, there was one fitter assembling the new units and one stripping the returned faulty units for repair.

A special transmission oil was produced which was tinted GREEN and called Drivex produced by Sternol Specialised Lubricants of Beeston, this had to be checked every 2,000 to 3,000 miles, and the filter removed from the hydraulic control unit and cleaned ever 5,000 miles. It appears that the main problem with the transmission tended to appear at around 10,000 miles, when the unit would refuse to change ratios. This was usually caused by wear between the rollers and the Toroidal cones owing to the large contact pressures. Oil technology has come a along way since the 1930s (see the article at the end by Bob Hayes)

It was rumoured at the time that General Motors paid Hayes and Austin a large sum to cease their experiments. Knudsen the director of General Motors did pay the Hayes Company $20.000 over three years for the manufacturing rights in the US, but this option was never taken up.

_______________

Various Press Comments

The Automobile Engineer

The ideal solution of the transmission problem, giving as it does a smooth variation of gear ratio between its two limits, and providing at the top end a very substantial overdrive. Probably one of the best features of the gear is the character of the control, for any driver who dislikes absolute automaticity can, in a moment, by the movement of a lever, change the drive into one over which he has complete control of ratios irrespective of engine torque or speed, and he is able to strike any compromise between the two extremes.

Sheffield Daily Independent

I have been driving the world's most remarkable car. In a hundred miles journey in town and country, batting along the bypasses at 60, crawling through London's heaviest traffic and stopping and starting on hills, every driving condition was met without a change of gear. It was no hundred horse-power car either. Just a big-bodied 31hundredweight Austin Saloon powered with a modest side-valve " six " of 18 h.p. The biggest-engined car in the world could not beat this Austin as a " one-gear " car, or even approach its astonishing flexibility.

Customers letter to the company, 16th November 1935

In March last I purchased an 18 h.p. York Saloon (CMH 252) with Hayes transmission and perhaps you would like to know how much I appreciate this form of transmission. On long journeys it makes driving far less fatiguing and in traffic saves all bother of gear changing. Turning into a main road is easier because speed can be reduced almost to a standstill without any trouble from the engine. A good view of the road both ways can usually be obtained without throwing out the clutch and there is no gear changing before or after turning. A striking feature is the very rapid acceleration especially from a standing start. I find that at traffic lights, for instance, I leave other cars far behind on re-starting and the rapid acceleration is also useful for slipping past other cars in traffic.

A very important advantage of this transmission is the increased m.p.g. Before I purchased my present car I had an exactly similar car without the Hayes transmission. For each car I kept for some months after purchase very careful check on petrol consumption and I find that the Hayes transmission gives an extra 3-31 m.p.g.

"After my experience of the Hayes transmission I should be sorry to go back to the ordinary gearbox."

Yours faithfully,

MT

_______________________

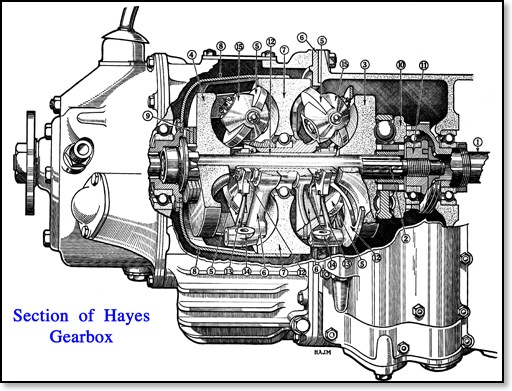

For those of you who are interested in how the system works, read on.

I have tried to keep it simple.

Toroidal Cone

It is this unique shape that allows the gearbox to work

![]() The Toroidal A is driven by the engine through a normal clutch.

The Toroidal A is driven by the engine through a normal clutch. ![]() This is the roller that transmits the power from A to B Consider this roller like a ball bearing that has the top and .............bottom part removed. this is then held in the centre by an arm that can rotate it radially.

This is the roller that transmits the power from A to B Consider this roller like a ball bearing that has the top and .............bottom part removed. this is then held in the centre by an arm that can rotate it radially. ![]() The Toroidal B is the output from the gearbox

The Toroidal B is the output from the gearbox![]() This is the link from B to the output shaft

This is the link from B to the output shaft![]() Output shaft

Output shaft

Please note that I have removed all the operating mechanism for clarity.

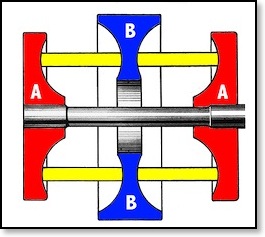

Because the drive plates are horizontal, and making contact at the same radius from the centre-line of the shafts Toroidal A and Toroidal B, then the input RPM from the engine which drives (A), will make (B) the output shaft rotate at the same speed but in the opposite direction (See Note A).

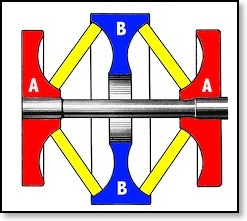

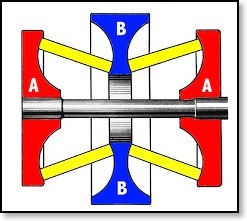

Low Ratio __________________ High Ratio

If the drive plates are tilted as above, then we can get a low ratio for moving away from rest. Or if tilled the other way we get a high ratio for cruising.

In this box the Low gear ratio is 4 : 1 and in High ratio for every rev of the engine the output shaft of the gearbox will rotate 1.7 revs.

When first moving off, you have to use the clutch as normal, putting the gear lever into the forward position. Remember that this box was not fully automatic, but once moving away from rest it would change up or down according to the engine power output and road conditions. Because optimum ratios selected by the box were selected automatically according to the varying road condition. It would always select the highest ratio possible so that engine speed would be around the rev-range that the maximum torque was been produced. So even if the road speed increased the engine speed and noise level remained the same. Some drives found this strange at first, but the big advantage was that the engine was working at optimum efficiency, so miles per gallon were greatly increased.

For reverse it was a conventional set-up, using the clutch and putting into reverse gear and controlling the speed of the car with the throttle.

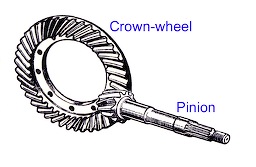

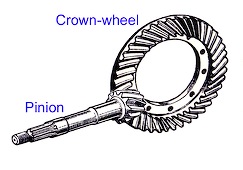

Note A. As the output shaft from the box is rotating the opposite way, compared to a conventional gearbox, it was necessary to modify the differential to correct this. So the crown-wheel needed to be rotated 180 degrees.

____ Normal Arrangement _____________Hayes Version

_______________________

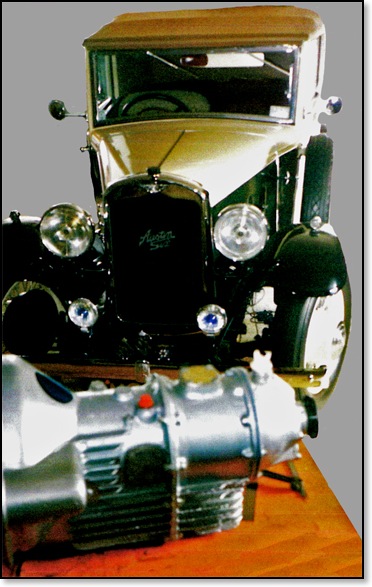

Article by Bob Hayes (no connection) living in New Zealand, about his Austin 18hp Berkley fitted with a Hayes gearbox.

Austin 18hp Berkley chassis, Salmon & Sons body & Tickford hood.

I first saw a photo of the car on the owners lawn, grass a metre high and growing up through the car which was rusty and rotten wood. I wanted it then, but it was about 4 years later before I owned it. My attraction to her was that I used to travel with an auto electrician during my apprenticeship 60 years ago in a 1931 Humber 12 with the same body, which incidentally I now also own and am in the middle of that restoration.

I was able to trace the previous owners of my Austin 18. It was first registered in North London Plate No BMC 307 in 1934 and owned by the Prince of Wales, shipped to NZ for the 1935 Royal Tour. The tour was cancelled so the car was sold to a doctor in Timaru. From there to a Donald Foster in Greymouth on the West Coast, Then to a John Houston about 1956 who took the car back to Timaru. At this stage the Hayes transmission was replaced with a manual gearbox, so the differential had to be turned over. Then sold to a guy Boyce in Christchurch who removed the motor to have it reconditioned, but failed to get it back, so the car continued to rot away on the lawn until I purchased it. I stored it for some years while we built a new home and large workshop. I was not prepared to start on the car until I knew I was able to finish it.

I then retired and it was all go. Stripped to bare chassis, located and rebuilt motor, gearbox and diff, made new cast iron brake drums. At this stage I noticed a few mysterious differences like a low ratio lever on the steering column and an oil pressure gauge for the transmission. This was my first introduction to a Hayes variable box. I advertised extensively to no avail.

So proceeded to fit a Borg Warner 65 automatic re-setting the valve body to suit the 18 motor. Made a lower stall converter and flex plate to suit. This was to substitute the variable missing box, then fitted an independent overdrive from a 3 litre Rover. I replaced all woodwork with new.

Repainted cream & green, re-upholstered in red leather, new hood. All new rims & re-spoked in stainless, new tyres and about a 100 pieces of chrome plaiting. I licensed the car and personalised the BMC 307 plate for obvious reasons, this was in 1996.

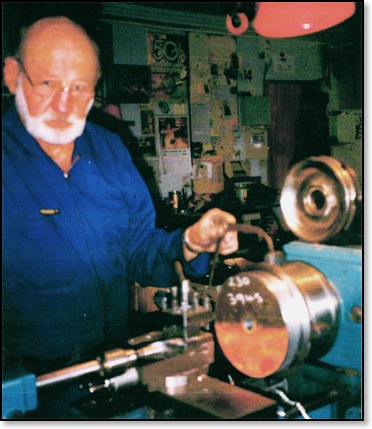

A few years later an advertisement appeared in an English Austin Magazine, For sale a Haines gearbox. I made contact straight away and, yes, it was a Hayes. It belonged to a Ralph Garrett in Leicester, I said I would buy it, and a price was agreed. The container eventually arrived and of course it meant a total re-build. I made all the necessary parts on my lathe, including the centre cone.

The next problem was finding the correct oil. This involved considerable research and looking for Drivex formula, the original oil. I tried normal Automatic Transmission Fluid and many others. Some diluted with kerosene. The next break-through was info on Torotrak, England, who were the original engineers from Leyland working on the Toroidal drive units. I was pointed in the direction of an American company who manufactures synthetic oil in Borneo. This solved all my problems. After a few miles I did have to make the centre cone again and a set of rollers. Have since travelled more than 10,000 miles. I would suggest one of the secrets of driving a Hayes box is fitting a rev counter and having infinite control from finger tip to the lever on the box.

To drive the Austin, it is easy to select the ratio. I change from town running to country touring. The overdrive is very high geared. Pleasant cruising speed is 50-55 mph but I have driven at 80 mph but-the hood flaps a bit at that speed.

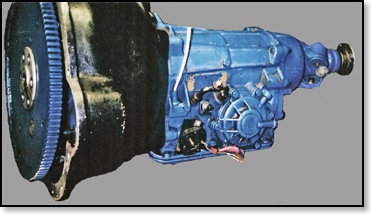

Gearbox installed

Car and Hayes Transmission