ECV 2 - Prototype

(Energy Conservation Vehicle)

ECV 2 Based On The ADO 88 Prototype

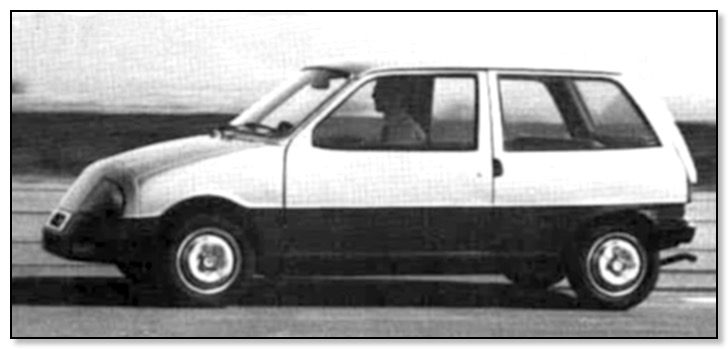

In May1980 BL Technology announced to the press its new testing facility at Gaydon Warwickshire. Also on show was the first concept car masterminded by Spen King under code name ECV 2 (ECV standing for Energy Conservation Vehicle).

The ECV 2 was based on the ADO88, acting purely as a running prototype for aerodynamic and running gear research. As the ECV 2 was based on an existing car, it was always going to be compromised as an overall concept, but it did prove invaluable as a test bed for the new (and at the time, very secret) three-cylinder power unit.

Headline figures for the ECV 2 were those for its fuel consumption: 100mpg at 30mph and, more realistically, over 60mpg at 60mph and 55mpg on the combined ECE dynamometer cycle. These figures may not seem so remarkable at the turn of the new millennium, but back in 1980, they were sensational – and Spen King insisted that BL cars should be performing to these standards by the end of the 1980s.

ECV 3 prototype

The future of cars, according to Spen King was Petrol, rather than diesel would be the fuel of choice for small cars, highly efficient multi-valve engines running compression ratios of up to 13.5:1.

Lean burn technology would be essential and up to 5 per cent of the cars in use would be powered by LPG (taxation permitting). CVT transmissions were the most efficient way of getting the power down, and therefore should be widely used. Tests by BL Technology showed that a CVT-equipped Dolomite returned 56mpg at 30mph compared with the 49mpg of its manual counterpart. King fervently believed that cars would need to become significantly lighter – he believed that a medium-sized family car would be up to 500kg lighter than the current models in 1980.

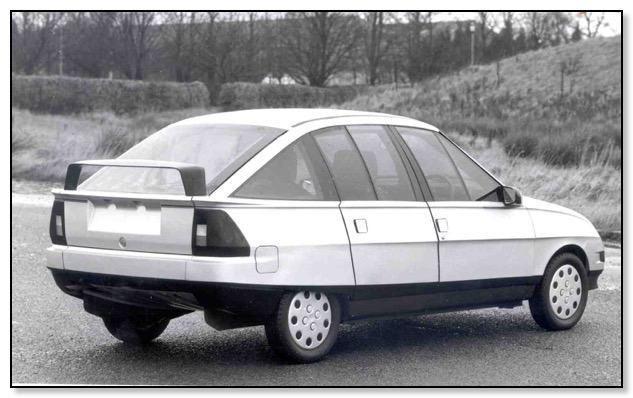

Steel and aluminium would be the choice of materials for cars’ structures, but with extensive use of plastic for non stress-bearing areas. Aerodynamics would also improve significantly by 1990 – drag coefficients would need to drop to below 0.30 to effect genuine improvements. He noted that the performance of the ECV 2 at 0.345 was less than satisfactory. It was also heavier than he liked at 560kg. With these goals in mind, King continued to work on the next version of the car, the ECV 3 – even in 1980, he was telling the press that the ECV3 would be ultra-aerodynamic and exceptionally light – and its three-cylinder engine would be matched up to a Borg-Warner CVT transmission system.

The ECV 3 Prototype

In December 1982, BL Technology revealed ECV 3 to the press – and, like its predecessor, it was made very clear that it would not be going into production, but would merely act as a mobile test-bed for new ideas and engineering concepts.

It might have looked bland from the front, but the ECV 3 certainly provided a preview of how the aerodynamically-honed cars of the 1990s would look.

Whatever the case, the ECV 3 was a fantastic car – and it harked back to so many BL and BMC models from the past, that it deserves a place in any account of the company’s history. Firstly, it was designed around the Issigonis maxim that it should have the maximum amount of interior space for minimum external size – and that it achieved magnificently, having more legroom than a Ford Sierra, while being some 2ft shorter.

Having sat in the car myself, there is certainly a competitive level of interior space in the front and rear – easily better than the Ford Focus, if not as good as the cars in the class above. A remarkable achievement for 1982, though.

The ECV 3 prototype

Maximum speed: 115mph

Acceleration: 0-60mph: 11.0 secs

Fuel consumption: 49mpg (ECE Urban Cycle)

61mpg at 75mph

81mpg at 56mph

133mpg at 30mph

So clearly, the performance and economy targets had also been met – maximum speed was comaprable to 1983’s crop of 2.0-litre saloons, while its economy was unmatched by any production cars of the day. Aerodynamics played a big part in this – its co-efficient was 0.24 and its weight was also phenomenally low at 664kg.

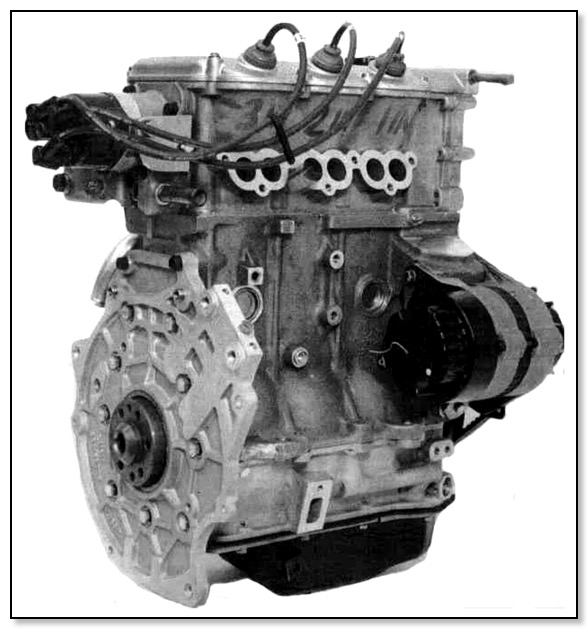

The 1113cc 3-cylinder engine used in the ECV 3 was unusual for being a single-cam, four-valve per cylinder design – efficient it was though: producing 70bhp at 5000rpm, with the promise of more to come. The ECV 3’s engine was somewhat similar to Spen King’s other design – the Triumph Dolomite Sprint. Many of the principles employed in the construction and design of this engine saw the light of day in the K-Series engine in 1989. Like the rest of the ECV 3, it was a featherweight, at a mere 84kg.

What was the ECV 3 prototype like to drive?

According to journalist Richard Bremner, who worked for Austin Rover at the time, it was a very interesting experience, ‘I remember a warbling three-cylinder engine, an amazingly elastic ride (though it did roll a bit) and limited transmission shunt, the bane of many an AR car at the time. If I recall, the triple had some trick engine mounting system that enabled the powertrain to rotate in sympathy with torque reversals, quite a feat given the need to hook a gearlinkage to it.’

The car’s construction was also somewhat different to that of its contemporary rivals, but it did turn to the ideals of another of the company’s earlier designs – the Rover P6. Like that car, the ECV 3’s body involved a load-bearing ‘baseframe’, to which unstressed panels were attached.

In this instance, the baseframe was made of aluminium and the panels were all plastic, contributing to the car’s low overall weight. In fact, the body-in-white weighed a mere 138kg, roughly half that of a contemporary steel monocoque.

Futuristic production techniques.

The AR6 was the car most influenced by the ECV 3 – and, most unfortunately, it did not make it into production. The engine did in a manner of speaking, because lessons learned in its design were used in the K-Series engine, which remained a highly competitive engine even into the new millennium.

The idea was very revolutionary for its time, and the use of aluminium, more so. According to Spen King, the technique has been picked up subsequently by Jaguar, ‘we worked with ALCAN on ECV 3, and when I got out of the company, I worked for ALCAN, and the people I brought in there out of BL are now running the ALCAN aluminium programme, which includes the Jaguar.

‘The techniques are directly borne out of what was going on in ECV 3. There’s a real connection. Mike Kelly and Tony Warren are the people in ALCAN who have been connected to ECV 3 right from the start.’

Overall, an exceptionally efficient package – and it did point to a brighter future…

Testing ECV 3 PROTOTYPE

B.L. Technology, a subsidiary of British Leyland, has perfected, under the name ECV 3 an experimental car already described in “Revue Automobile”. Nevertheless let me recall that we are talking about BL perfecting a car, which could be produced by means of technologies applicable to mass production and at a reasonable price in the relatively near future, with interior dimensions of a current medium car and performance of a car in the 1.6 to 2.0 litre class.

Moreover, consumption would be much lower than current standards for these cars. In this latter area, results achieved are:

3.50 litres/100 km at 90 km/h steady speed

4.60 litres/100 km at 120 km/h and

5.75 litres/100 km for the urban cycle.

It is worth noting that these figures were obtained without exploiting all engine management possibilities (ignition advance mapping, over-run cut off, best use of the 4 valve per cylinder head, notably by using different timing diagrams for the two inlet valves and individual tuning of their ports). As it is, the car is a first shot and its development continues.

According to the builder, this 3 cylinder of 1113cc and 72 hp reaches a speed of 185 km/h and accelerates from 0 to ‘100 km/h in around 11 seconds and to 160 km/b in 35 seconds. Such a combination of high performance and low consumption has been made possible in the main by the following measures. Low weight: with its aluminium structure and external coach work in plastic, the complete vehicle weighs no more than 664 kg with a full tank (30 litres)

Very effective aerodynamic shape: CD quoted between 0.24 and 0.25 depending on the opening of the cooling air intake. Optimum engine output: Only 3 cylinders, whence a better individual cylinder, and lower frictional losses. Further the BL engineers found that via suitable mounts, the first and second order out-of-balance couples, characteristic of 3 cylinder engines are more easily isolated with engineered compliant engine mounts than the second order out-of-balance forces of a vertical 4 cylinder engine. For the latter case, indeed, the compliance of the mounts is limited by low frequency heave of the engine set up by road irregularities.

At the Wheel

We had the privilege of being able to drive the ECV 3 on BL’s test tracks at Gaydon, laid out on a disused airfield. Inspection of the vehicle dimensions shows that the interior width of the body is rather less in comparison with that of current medium cars (3 cm less than VW Golf, 7 cm less than Peugeot 305) but at the wheel it gave a “small car” feeling. Although my passenger for the occasion wore an overcoat we had no problems of overcrowding. On the contrary, the head-room and leg-room, as much in the rear as in the front, are very generous.

In its fuel injection version, the engine starts on the first turn of the starter and in the first few hundred yards it was evident that in the area of performance the BL engineers had hit their target. I have never driven a 1100 cc saloon (with 5 doors as well!) which had such acceleration. Although designed above all to give good torque at relatively low speeds (maximum torque is delivered at 3750 rpm) permitting it to pull long gear ratios favouring fuel economy, the engine climbs through the speed range very briskly. Top speed, achieved in fourth gear, corresponds roughly to the engine speed for maximum power (5800 rpm), but even in fifth gear (38.5km per 1,000 rpm) performance is still acceptable. As is typical for a very low drag car that even after a long run up the speed is still increasing. The car continued to accelerate until it became vital to lift off at the end of the longest straight on the track, with the speedometer (which I am assured was exact) showing 110 mph, which is 177 km/h.

Although we were still in fourth gear, the engine had not become noisy and one did not detect any vibration or buzzing. In fact, the noise emitted was a little reminiscent of the Rover 2600 engine. For such a light vehicle, ‘the ride comfort ‘is of the highest order. Even on bad roads, bumps are well absorbed and do ‘not produce excessive resonance’s. The rack and pinion steering is direct enough (2.8 turns lock to lock) and the front suspension has zero ground offset. In spite of being direct, the steering remains very light, which is what you would except with such a low weight of vehicle. But the road behaviour still lacks sharpness indeed such as we drove it, ECV 3 under-steered in an excessive manner which made it feel less nimble than one would expect on the part of such a light car. Further it was certainly difficult to achieve an entirely satisfactory behaviour under all conditions from a car whose useful load is much higher than half the empty weight and moreover whose rear suspension takes the greater part of load variations. We think nevertheless, that a distinct improvement could already be achieved by improving the tuning of the low rolling resistance tyres whose slip angles seem high to us. We don’t doubt that a firm such as Dunlop will be able to remedy this disadvantage.

To drive a car like ECV 3 is to open a door on the future. When one thinks that, for reasons of time and lack of funds the builders have intentionally foregone recourse to certain known solutions which will be the object of further research (notably a continuous and automatic transmission, with electronic control permitting the engine to be always working in the most favourable area of output), one understands better the amount of progress which the future still holds in the field of the automobile. But, for the moment, the greatest merit of this piece of work is to remind us that the British Car Industry is not as asleep as one could have believed, and looks to the future with a certain assurance. Many of us had begun to doubt this.