Austin Fire Brigade

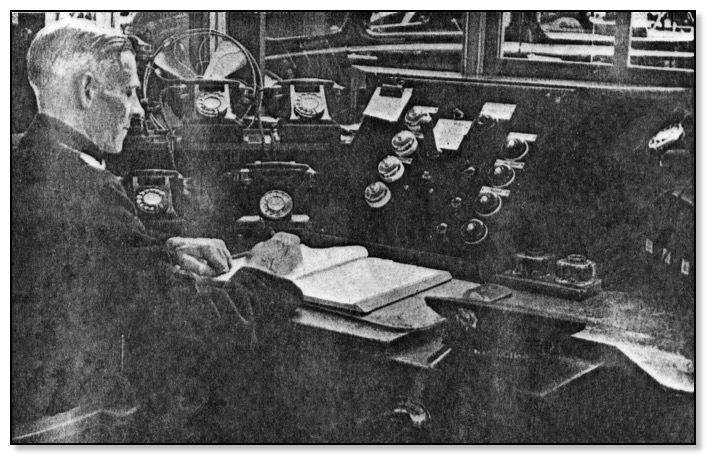

Control Room where a constant watch 24 hours a day is kept.

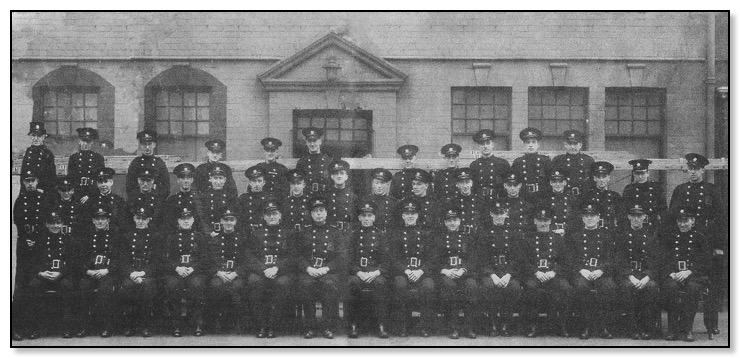

One of the world's great motor car factories is that of the Austin Motor Co. at Longbridge, near Birmingham. In this enormous plant, which covers some 250 acres and employs nearly 20,000 men and women, there are problems to tax the capacity of the best fire prevention and fire-fighting brains in the country, in addition to responsibilities which could be adequately carried by only the finest type of fire-fighting personnel. The Austin Fire Brigade, under the direction of the company’s superintendent of fire service Mr W A T Marchant AFICD, is very much a picked body of men. It consists, beside Supt. Marchant, of two officers and 23 other ranks, all fully-trained professionals. That these men are well fitting round pegs in round holes is evident from the fact that their average length of service with the brigade exceeds tell years, while their average service with the company exceeds 14 Years.

The equipment of the brigade includes two motor pumps, two tenders and a hose van, three large and two small trailer and a foam trailer. Foam appliances and compressed air breathing sets are carried in both pumps and in one tender. In the appliances, in hose boxes throughout the factory, and in reserve, are more than 16,000ft delivery hose. Two ambulances are manned by the brigade to look after cases of sickness and accidents.

The fire station consists of a main bay for the appliances, control room workshop, hose room and stores, mess room and locker room, adequate facilities for washing, including showers, as well as a lecture room and lecture Supt. Marchant and his deputy.

As in all industrial brigades, the most important part of the duties of the Austin Co's firefighting organisation is to originate, carry out, and where necessary, enforce every possible device and every practicable regulation to prevent an outbreak of fire. In view of the frequent necessary changes in layout and rapid extensions of the Longbridge factory this has been no easy task, but by means of good organisation and with the close co-operation of the departments and the management, Supt. Marchant and those serving under him have been enabled to keep abreast with all new challenges.

An example of the many tricky problems that are liable to crop up in a works of this kind came to light nearly two years two ago when, according to Supt. Marchant, it was found that petrol tanks which had proved to be defective, or damaged, after they had been assembled to new vehicles were being returned for rectification without having the residual petrol removed. Clearly, this practice held serious dangers, even though the number of tanks involved was very small indeed in relation to the total output.

In the result it was arranged that the tanks should be sent to the fire station for purging before being sent back to the manufacturers, and this has been done ever since without untoward incident. During 1953 more that 700 petrol tanks were thus " neutralised " by the brigade, an average of something like two a day.

Throughout the works there are 1,675 extinguishers: these are inspected, and cleaned, at intervals of approximately a month. According to type and age they are withdrawn to the fire station for complete testing intervals.

Here it may be stated that as a general policy the company has decided to replace the soda-acid type by the water CO2 principle which, it is claimed, has a number of advantages in operation, maintenance, and recharging. The CO2. systems aggregate more than 9,000 lb of gas.

In view of the obvious advantages of chlorobromome-thane is acquiring a number of extinguishers using this newest medium, but they will be handled solely by brigade personnel.

The piped installations include sprinkler, Mulsifyre, and CO2 systems throughout the various departments of the factory. During the last few years the brigade has taken on the inspection and the maintenance of these systems. When, as a result of inspection, major repairs are found to be necessary these are dealt with by engineer’s maintenance departments.

"There are, of course, strict standing regulations which oblige the maintenance staff and contractors to inform the fire brigade when any cutting, or welding, is to be done and any such work is not permitted to begin until a fireman has visited the site. If, after inspection. he is satisfied that it is safe to undertake the work without a fireman in attendance, he hands to the welding operator a permit specifying the date, nature of work, and the place where it is to be performed.

The welding operator is left with instructions as to the nearest telephone and the method of summoning the brigade, and is provided with suitable extinguishers to cover any minor outbreak. In all other cases the fireman ensures that the site is made as possible and in attendance until the work is completed. Stand-by duties of this kind in 1953 accounted for no fewer than 2340 hours of the brigade's time.

It goes without saying, perhaps, that the brigade maintains a 24 hour watch, and night patrols throughout the plant are carried out every day of the year. The telephone system is used exclusively for calls. But in fact, during 1953 the brigade received only 224 calls, about three-quarters of which were to fires that had been already extinguished, or partly so, by men in the shops. This is many fewer than the number received in plants of much smaller size. Only 64 of the calls required attendance of a major appliance, a figure which was about 14 per cent. below that of the previous year. The brigade is also called upon from time to time for special services, like any local government fire bridge. During the past year these covered such items as removing, acid from roads, filling disused underground tanks with water, and so on. The ambulance were called out 79 times during the year, 50 cases of sickness were taken to hospital or to the patient's home, while only 29 journeys were needed for accidents.

PS. In 1964 there were 42 Full Time Firemen employed

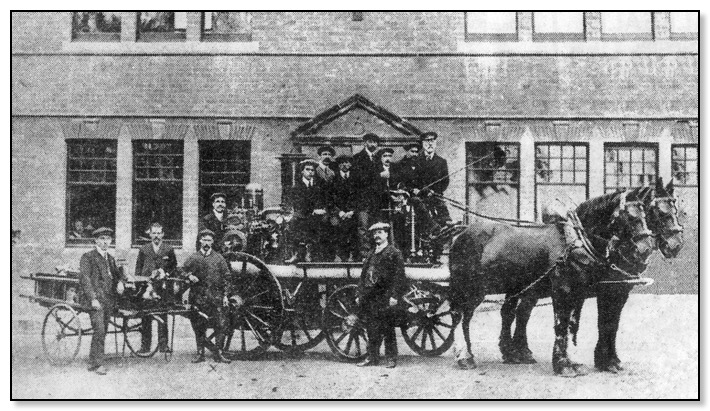

The Austin Fire Brigade Through The Years

Austin Works Auxiliary Fire Service

First Long-service awards for firemen

Although starting off with a centre gear change, this was changed to the steering column, to bring it in line with the saloon in autumn 1951.

Mr R D Niven, Works Directors, presented the first-ever long-service awards to members of the Longbridge Works Fire Brigade. In the picture watched by the Chief Fire Officer, Mr G Stinchcombe, and members of the Brigade, Mr Niven presents a silver metal and bar to Deputy Chief Fire Officer H Heathcote who has 27 year’s service as a works fireman to his credit, plus three years as a civilian fireman.

In the background are other fireman who received awards – the first figure following their names below denoting length of service to the Company, the second their length of fire service, including national and AFS, (Left to right): Leading Fireman A. Berry, Silver Medal,and bar, 24/26 years; Sub-Officer S Cutler, W. Wall, silver medal, 38/25; L/Fm. S Albutt, Silver medal 39/25; B. Wiley, silver medal, 35/25; Fm. A. Blake, silver medal, 35/25; Fm C. Gibbs, bronze medal and bar, 16/24; Sub-Officer L. J. Partridge, bronze medal and bar 5.5/16.

A bronze medal was sent to the widow of Sub-Officer B. Cooper, who joined the Company in 1948 as a fireman, after nine years with the AFS. He died in December. L/Fm. W. Steed, silver medal and bar, and L/Fm. W. Feeberry, bronze medal, were unable to receive their awards in person.