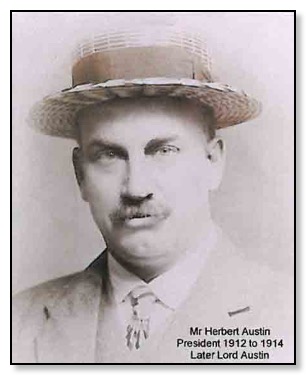

This is the Story of Herbert Austin

from Boy to Lord.

(known to all who worked for him, affectionally as) "The Old Man"

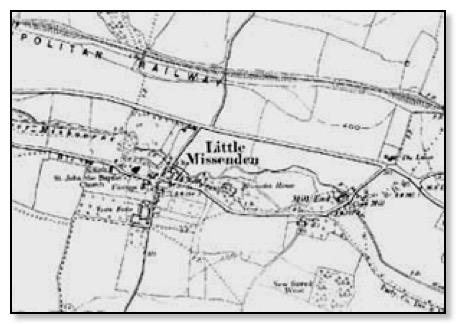

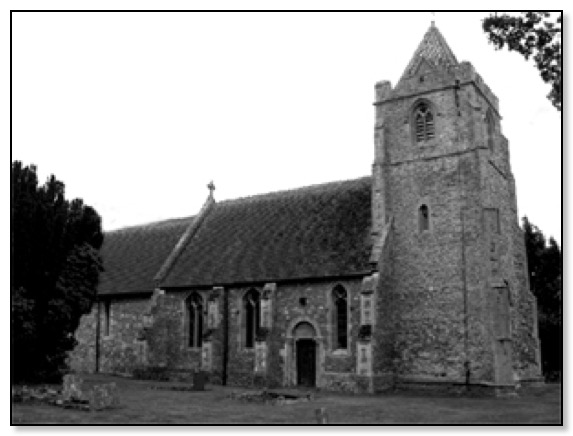

Herbert Austin who was born on the 8th November 1866 to Mr Giles Stevens Austin, a farmer and his mother Clara Jane Austin daughter of Willoughby Simpson, an officer in HM Customs. They lived at Grange Farm, Deep Mill Lane in the small village of Little Missenden, Buckinghamshire which lies in the shadow of the Chiltern Hills. He was christened Herbert Austin at the local Parish Church of St John The Baptist.

After four years the family moved to a small village in Wentworth, South Yorkshire, his father becoming Farm Bailiff to Earl Fitzwilliam. The family grew with Herbert having three brothers named Walter, Jack, and Harry, and later a sister joined the family who was named Albreda. In this small community there was very little to do as a small boy, so as he grew up, it became obvious to his parents that his talent lay in the way of drawing. At the age of six he would spend many hours especially in the winter months at the large table making freehand drawings of various subjects.

It was his ability to draw anything mechanical which gave him the most enjoyment. Friends and family used to be amazed that this small boy could produce drawings that were of a geometrical nature that had the right sizes and proportion to be almost three dimensional. This skill was something that stayed with him through out his life. What was even more surprising was that nobody in the family before-hand had shown this aptitude.

Rotherham Grammar School

When he was older, he attended the Rotherham Grammar School, which meant a daily round trip of 10 miles on foot come summer or winter. Along with his passion in drawing his artistic skills were also to show in his interest in music, and spent many hours enjoying the works of great composers. He became a chorister in Wentworth St Peters Church. Sadness hit the family when Herbert's younger brother Ernest of 3 years, fell downstairs braking a leg which became gangrenous and after a few weeks he died.

Wentworth St Peters Church

After leaving Rotherham Grammar School he attended the Brampton Commercial College for about two years. It was at this point his parents decided that his artistic talent could be used, so that he should take up a profession in architecture. As his uncle was architect to Earl Fitzwilliam. who had shown a willingness to have Herbert join him, so an apprenticeship was entered into. This arrangement did not bode well, as Herbert's heart was really in engineering. So it was not long before the Uncle was having words with Hertbert's parents that the apprenticeship would have to be cancelled.

GNR Motif

So his parents decided to apply for an apprenticeship with the Great Northern Railway. This Railway Company had been formed in 1846, it expanded and took over many small railway companies of the day, with its main activities been the transporting of coal. There were no vacancies at that time, but Herbert was duly registered, and it was arranged that he should enter upon his five years' training immediately a vacancy occurred.

He was determined to improving his skill in freehand drawing, and won several prizes for life-size crayon enlargements from photographs. But it was in drawings of mechanical objects that he receive most distinction.

It was whilst waiting for a vacancy with the Great Northern Railways that he remembered that his mother had a brother in Australia who had always been going on about what a fascinating country it was. Being a young country that need men who were willing to work hard and it would reward them richly for there efforts. So this was to become his vision for the future.

His uncle who was managing a engineering firm in Melbourne was going to visit them in a few months time, so was this the break he needed, could he convince his parents that he wished to go back with his uncle to Australia.

With uncle's visit now only weeks away, it was time to put his plan into action. So he would seize an opportunity to get mother by herself (how many times have we done this) and convince her that he would like to return with his uncle to Australia. It appears that over time she could see that he would only be happy if this could happen. Now it was only a case of convincing father, but with mother on his side it wouldn't be too difficult.

A few days after his uncle had arrived, the question was broached. His uncle said that he was happy to take him back to Australia, so after further pleading with his parents, permission was finally granted.

So yet again his apprenticeship, this time with the Great Northern Railway had to be called off, as now it was a sea voyage to the land of opportunities.

Australia

Thy set sail on the Austral ship on a journey that would take two months. I am sure although at times he wondered when he would arrive, his time would have been put to good use. For a young man in his late teens he was very focused, and no doubt used his time to draw and plan out what he would do, down under.

On the day they arrived in Melbourne it was the hottest the city had experienced for many years. The next day his uncle who loved horse racing took him to see the 1884 Melbourne Cup. Next day he was in the Northern Melbourne engineering shop where his uncle was manager for the Scottish owner Mephan Ferguson. This small workshop contained a foundry and small forge a some lathes and drilling machines. It was here that he received a grounding in general engineering particularly been a mechanic. The company was of medium size but soon grew with this canny Scot in charge. One thing he would never allow was to work on a Sunday, but come Monday morning it was all hands to the pump and this probable was good grounding for Herbert, that if you want to succeed you have to work for it.

It is interesting that his inventive genius, which had lay dormant, was now showing through. As having only been in Australia for about a years, had already applied for his first patent in the form of a locking plate for railway fish-plates. He showed that he was willing to have ago at anything that would involve his engineering and design skills.

In his spare time his passion for drawing was catered for by attending the Hotham Art School again in Melbourne, and as was the case in England his work surprised his teachers. Although he was in the Junior Section of the school, his work was of such high standard that his work was put in the Senior Division for marking, and even then he carried away the first prize. So this was the first stage in him becoming a automobile designer.

After two years he felt that it was time to move on, so severing the family ties with his uncle he moved to another Melbourne company called Cowan, which imported and installed printing machines and Crossley gas engines. This again lasted about two years but in those years he obtained more skills which would be useful later on.

He was only twenty one when the Government of Victoria invited designs and estimates for a swing bridge over the Yarra River at the end of Spencer Street, Melbourne, This would be a real challenge, so it was only possible to work on the design in the evenings and some weekends. His designs and estimates were duly submitted. He was not successful, but was told that for such a young man he was very talented.

Still in Melbourne he now joined the Langland’s Foundry Company. This company had more bearing on his engineering life that the others. He was quoted as saying, "I have mixed memories of this particular shop, but I feel that I owe to it a very great debt of gratitude, for it was here that I received a thorough training as a mechanic."

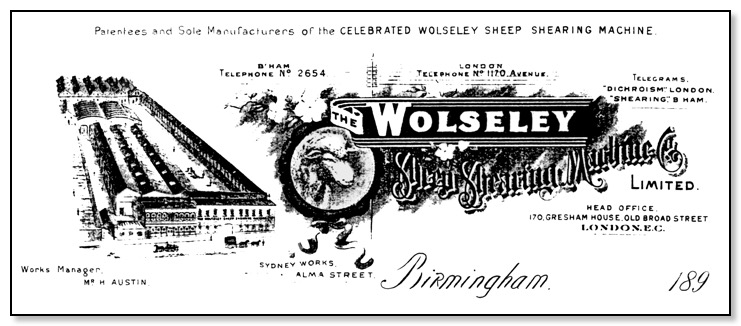

He met and fell in love with an Australian girl, Helen Dron whose parents had moved from Scotland and settled in Melbourne. Three days before the wedding he gave his notice in to Longlands and the wedding took place on 26th December 1887 in Melbourne. They could not afford a honeymoon so after the reception went to their new house in Melbourne. This time he started a new job as manager for £3 10s a week with Richard Pick-Up Parks, they were developing a new sheep-shearing machine for an inventor named Frederick York Wolseley. Frederick over many years had decided that there must be a way of mechanising the shearing of sheep and around 1875 took out a patent on his invention. To prove that the sheep shearing machine would prove a winner in the field, he bought a large sheep station near to Walgett, New South Wales. This gave him the time to perfect his machine, so 1887 he founded the Wolseley Sheep-Shearing Company in Sydney.

Herbert Austin soon realised in this capacity working with the Wolseley Sheep Shearing Company, from which his firm had obtained an order. That he was able to see various weaknesses in the machinery, which he pointed out to the manufacturer. Several of his suggestions for improvement of the machinery were adopted by the Wolseley Company. Obvious this impressed the Wolseley management, because he was later offered the post of engineer. His first task was to study how the machines in the hands of the operators at a sheep-shearing station at Avoca were performing. Herbert decided to improve the design, and in fact took out patents in his own name. The company moved to Sydney and Herbert signed an agreement with the Wolseley Company on 10th March 1893 to exchange his right to the patents for eighty fully paid £5 ordinary shares. Some months later the company offered him a directorship of the British company, which meant going back to the UK.

_________________________

Returning to England

Herbert wife was looking forward to going to England for what she thought would be a short stay. It was necessary to sell the house at a reduced price for a quick sale. His wife and first child (Irene) were not well when they boarded the ship for the UK.

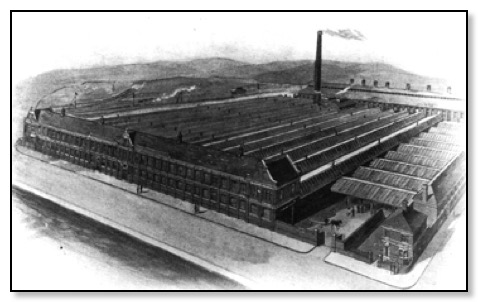

The ship landed at Tilbury in November 1893 with the family still not well. Herbert took up his position as manager and got down to addressing the poor quality of the machines. It was decided to actually repurchasing the whole of the faulty machines, some could be rectified but most were scrapped, this procedure costing the company a great deal of money. Frederick York Wolseley Managing Director resigned in 1894 and the board in March 1894 renewed Herbert contract for a further year. He then rented a house in Melville Road off the Hagley Road Birmingham for an annual rent of £35. After about a year the family moved to 7 Calthorpe Road Edgbaston. In the first ten years of Herbert Austin controlling production, things were very tough because the company's capital had been largely consumed in connection with the shipment of faulty products. With a view to keeping the cost down to the minimum, the company decided to start a workshop in Birmingham mainly because of the fact that most of the machine parts were produced there. The first premises were in Broad Street, and chosen because of their cheapness rather than with an eye to convenience. Operations had to be conducted with remarkable economy, Herbert Austin had learned his lesson during his years in Australia, and was now able to impress upon his directors and his men that, in order to be good enough for overseas conditions, machinery had to be of the very finest quality. Second-rate apparatus could not function without failure under conditions which were so very severe. Even though he succeeded in impressing upon his own men the urgent necessity for exactitude and care, still he was faced with shortcomings in the parts supplied from outside suppliers. Because of the need to produce all of the components in house they would need to move to larger premises. Austin saw that a factory in Alma Street, Aston was up for sale, so without the boards permission he went to the auction and bid £5,000. The Wolseley Directors said that they would not honour the bid, and Austin would have to fund it himself. After much debate the board did finally approved the purchase and the company into Sydney Works, Alma Street, Aston, Birmingham. At around the same time another move was taking place with the family moved to a new house in Berwood Grove, Erdington, where their only son Vernon was born.

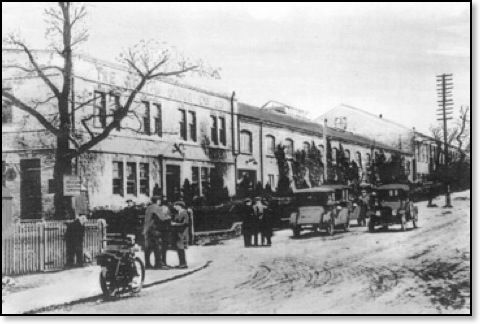

Sydney Works Alma Street Aston Birmingham

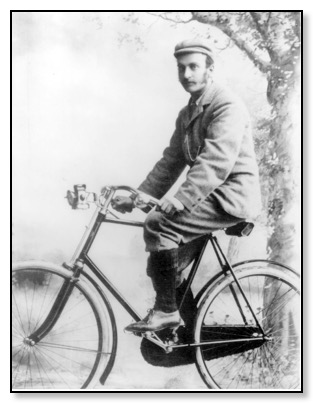

It was now that the company looked at other products to keep the workforce and machinery busy. This took the form of making machine tools principally for cotton machine makers. With a large number of cycle manufactures in the Birmingham and Coventry area this was an ideal outlet to supply. Herbert Austin even designed a bicycle, but was never put into production. Another side line was machine tools, and at Alma Street thy produced the first vertical semi-automatic chucking lathe, which was considered to be a remarkable piece of workmanship when exhibited at the Paris Salon.

Owing to Austin's love of cycling, he looked at the possibility of been an agent to sell bikes to Australia, and in fact did so for about three years. But it was the motor car that was his dream, so he tried to convince the main board that they should produce their own car. But the Board were not willing to back him, this did not dampen his enthusiasm, so in his own time he set to work on making his own car.

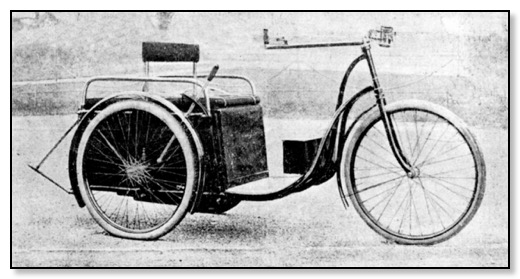

The Wolseley Autocar No. 1

Wolseley Autocar

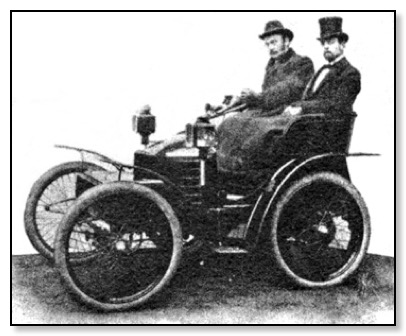

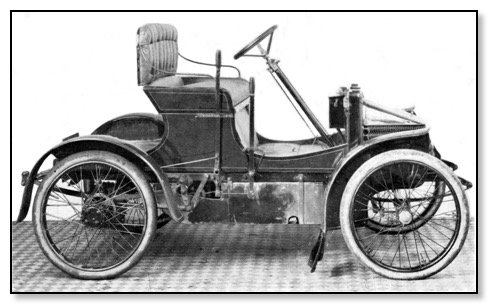

After various experimental versions the Wolseley Autocar No.1 was born. It was a three wheeled design (one front, two rear) featuring independent rear suspension, mid engine and back to back seating. The public first showing was at the Nation Cycle Show Crystal Place and was priced at £110 for a two seater version and £150 for a four seater. It came with a six months guarantee and if you broke down, a mechanic would be sent from the factory at minimum cost. In June 1898, Herbert Austin drove a Wolseley car to Rhyl and back a distance of about 255 miles, averaging around eight miles per hour, carrying two passengers without experiencing any kind of breakdown. The end result was it received favourable comments from the board and they decided to fund a four wheel car, this was called the Wolseley "Voiturette" in 1899. In 1900 his latest baby was entered in the 1,000 miles trial, which proved successful and on the strength of this the board elected him to the board as a director in 1901.

Wolseley Voiturette with Herbert Austin at the wheel

He was concerned that because of the cash restraints, his vision for the future would not materialise without an injection of money, from outside the company. Herbert Austin was at the time in touch with Sir Hiram Maxim (Vickers Shipbuilders) so he approached the company Vickers Sons and Maxim with the suggestion that it should take over the machine tool and motor side of the Wolseley concern. At this time the great shipbuilding firm was in the heyday of its success, and was prepared to consider any additional enterprise that looked promising. A deal was put to the Wolseley board, which was accepted, and Herbert Austin was made General Manager, with the company renamed The Wolseley Tool and Motor Car Company. With finance behind them, they bought a factory called Adderley Park that was vacant for £31,545 to replace Alma Street.

Adderley Park 1901

It is interesting that although he was now the General Manager of Wolseley, part of him wasn't sure it was right for him. As he was quoted as saying, "In a sense it is possible that I made a mistake when I took over the management of Wolseley Company for Messrs Vickers, in that I did not commence to build cars on my own account. It would, of course, have had to be in a very small way, but it might have been better from the personal stand point, than managing somebody else's business. It would have been a slow process, however, and also somewhat unsafe."

So what were the main problems for the car manufacturers of the time. it appears that there were three main areas that affected the reliability of the vehicles.

A reliable ignition system, as at the time only the hot wire type was available. Next came the tyres, which partly because of the poor roads in some areas, punctures were quite frequent also the milage covered per tyre was very low. Transmission in the form of the gearbox, were very noisy and they had very wooly gear changes. It is this area that Herbert Austin came up with the universal gate change in 1895. In the early years, Wolseley cars used horizontal engines, but later on changed to the vertical type that soon became the norm.

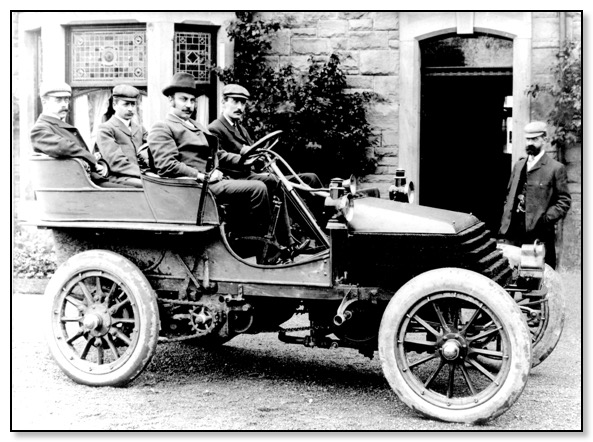

Left to right Schmidt (Draughtsman) A A Remington (In charge of the drawing office)

Herbert Austin, Mr Collins (Test Department) and Alfred Hitchon

Wolseley’s Latest Model

Financially the company was now on a firm footing, as in 1901 from February to December the turnover was £22,368 by 1903 the turnover had risen to £171,136. With the rapid growth of the car business, the machine tool section took a back seat. So the Wolseley range of cars expanded and production increased, showing that with Herbert Austin leadership the company was moving forward in the right direction.

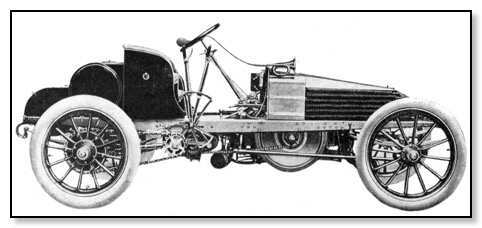

The range of vehicles produced increased over the years, from a Racing Car in 1903 to a Baby Wolseley in 1905.

1903 50hp Racing Car

1905 5hp Baby Wolseley

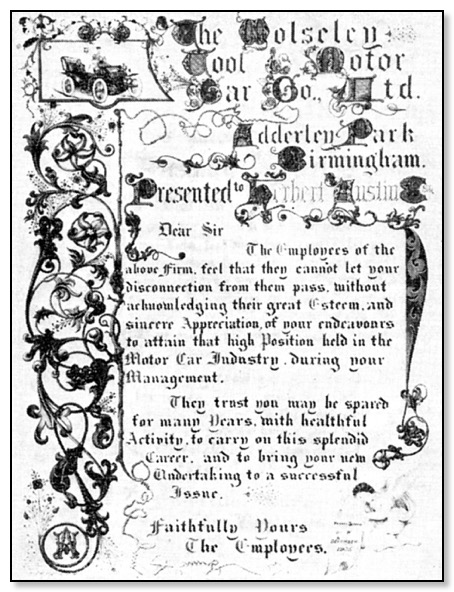

In 1905 Austin and the Vickers management had a disagreement, it revolved round the design of the engine. Austin was passionate that the horizontal engine was the way to go, but the general thinking at the time was that the vertical layout was best. The board backed the vertical design and so Albert Vickers presiding wrote a letter to Austin asking for his resignation. Austin replied and asked the Company to purchase back his second Mortgage debentures. Austin felt that he was unable to steer the company his way, so this was the catalyst that made Herbert Austin start looking for a place that he could call his own.

On the day Austin left the Wolseley Company, he was presented with an illuminated address by the employees.

The employees of the Wolseley Company feel that they cannot let your connection with them pass without acknowledgement of their great esteem and sincere appreciation of your endeavours to attain that high position held in the motor car industry during your management. They trust you may be spared for many years with healthful activity to carry on this splendid career, and to bring your new undertaking to a successful issue. -------------------------------------------------- Faithfully Yours The Employees

_________________________

Herbert Austin Sets Up His Own Company

To set up his own company, Herbert Austin needed people with design skills. He had been impressed by a junior draughtsman who had started work at Wolseley in 1903, his name A J Hancock. Having been approached, he agreed to work and soon was working on the first Austin car at Herberts home in Berwood Grove. A bedroom was suitable turned into a drawing office, but he soon realised that he need more help if the drawings would be ready around November 1905. Hancock suggested that Herbert employed Davidge who was still working for Wolseley. So Herbert agreed to this and at the same time, Bobby Howitt was appointed as private secretary.

Just how much capital would you need to set a car company in 1905, well it appears that £100,000 is the minimum needed. At the time he had only £15,000, but what he did have was this reputation that brought with it design and management skills. Some of this capital came partly from a son of an old friend, Captain Frank Kayser, (who owned various companies, including a steel company in Sheffield) he was his only partner.

At the time, his candid friends ridiculed the idea of starting a motor manufacturing company on his own account, and especially doing it seven miles from the centre of Birmingham. But as the empty workshops at Longbridge were of a size convenient for his immediate purpose, and there was available plenty of space for expansion. With the Great Western and Midland Railway lines having siding accommodation, even though he had modest financial resources he could scarcely arrive at any other decision. After all it was not that far from the manufacturing centre of Birmingham which could supply all his needs in the early years.

With a small team the first Austin car was designed, ready for the Motor Exhibition to be held on the 17th to 25th November 1905. Because he did not have a prototype built and cash was short, Harvey Du Cros who was the sole importer of Mercedes cars allowed Austin to display the drawing of his first car in a corner of stand 23. There was considerable interest shown, and in fact a few orders were secured.

It was very important that these first orders were delivered as soon as possible, thereby improving the cash flow. With Austin at the wheel the first car drove out of the works gates and up the Lickey Road in a cloud of smoke.

The first production Austin car produced was delivered in August 1906 to its new customer who lived in Richmond, Surrey

First car on test up Lickey Road

For the Olympia Exhibition of November 1906 Austin this time had his own Stand No 136. Two cars were shown along with two chassis allowing the public the opportunity of seeing the suspension and transmission. One car described as a Limousine powered by a 25 - 30hp engine and priced at £800.

About a year afterwards, Harvey Du Cros joined the firm, and later on various members of the family furnished the additional capital which enabled the company to expand.

His main problem was to get a skilled workforce that would be willing to travel to Longbridge. But this is what we would call today a green field site, although he would have to adapted the buildings from tin box printing to motor manufacture. It was because he had worked his way up from the shop floor to management in an engineering environment, he was able to do any job and had the knowledge of knowing what facilities were needed. This ability proved invaluable when employing workers, as they soon respected his judgement, although they may not have always agreed with everything he did. He no doubt kept a tight reign on his workforce, and was able to implement different working procedures that would have not been possible at Wolseley. The old-times at Longbridge used to say that the "governor" is able to see round corners.

One thing you need when producing cars, is a dealer network. Herbert Austin had no problem in setting this up, because of his Wolseley connections he was able to contact various distributors at home, the Colonies and elsewhere. At the time the sole selling export agent was put in the hands of Mr R G Ash who had his own company. This carried on till 1912 when Mr Ash joined the Austin Motor Company as the export director to expand the markets overseas.

At the end of 1913 Austin and Frank Kayser decided that they needed more capital to finance and expand the business. The three main shareholders were Herbert Austin with 186,663, next was Harvey Du Cross (Dunlop Rubber Company) 18,663 and Frank Kayser with 26,662. Austin would become chairman and managing director on a five year contract at a salary of £3,500 a year and 2.5 per cent of the net profits in each year. All this was signed and sealed in February 1914 and the company was renamed The Austin Motor Company (l914) Limited. With net turnover at over £400,000 for the year, allowing for all expenses, depreciation and the setting up of the company, it made a healthy profit.

Northfield Golf Club

Handing out the Golf Trophies

Herbert Austin often enjoyed a game of golf, playing at the local Northfield Golf Club. In 1907 the Cadbury family had a golf course built not far from the Longbridge site. The course was designed by James Braid, one of the greatest golfers and golf course architects of all time. It was originally called Northfield Golf Club but later changed its name to North Worcestershire Golf Club as in those days it was actually in Worcestershire. Herbert Austin was President of the golf club from 1912 to 1914 and was influential in shaping the club.

K Gate early 1910s

Although Austin was happy at the time taking the company public, when asked in the late 1920s if he though that was a good think he made the remark, "The truth is that was the biggest mistake I ever made, had it remained a private concern its development would have been more personal and less spectacular'

In recognition of the important service Herbert Austin rendered to his country during the war years, (Link) he was created a Knight of the British Empire in 1917. He was also honoured with the Order of Leopold for war services to the Belgium people. It was sad that his only son was killed in France in January 1915.

After the war it was now time to reorganise the factory back to car production. The company were able to exercise the option of buying the North and West Works from the Government. Of course the workforce had to be slimmed down as Government contracts came to an end. It must have been a very difficult period to decide what type of vehicle to put into production, and how to price it. To try and kick start the market, the first model introduced was the Austin 20, which was sold at a very low price. Sales did not really take off as most people considered it as too big. But then came along the Austin 12 which was popular. But the real boost in production and profit came with the Austin Seven.

In October 1918 his daughter Irene Austin married Capt. A. C. R. Waite who joined the company and was involved in the Racing side of the company.

_________________________

Herbert Austin becomes an MP

Although he had no particular yearning for a political career, there was a feeling after WWI it was time that to get the country back on its feet, the Government should include business men. So Herbert Austin was persuaded in 1919 to stand as a Unionist member for the Kings Norton Division of Birmingham, which covered the Kings Norton, Northfield and Longbridge areas where most of his workers lived.

He was duly elected and sat in the house of Commons until 1924, but felt frustrated with the Government, as when it was time to be re-elected he remarked, "I have no intention of standing again for Parliament, because I am convinced that the business men of England, including myself, are best engaged in giving the whole of their attention to their own particular jobs, and thus bring about a solution of the country's difficulties by natural means. The thriving condition of the Longbridge factory to-day will do more, for example, to minimise the evil of unemployment than could all my efforts on the floor of the House. In making these statements I do not wish to create-any wrong impression. I do not wish to infer that I regard Parliament as a home for nonentities, or as a place from which no good thing can emanate. I just wish to point out, that men such as myself can accomplish more outside than in.

Despite this, I remain convinced that the argument promulgated in 1919 still holds good to-day, and that England does need to be governed in a businesslike fashion. After all, government is a huge business, and needs to be run on lines exactly similar to those along which any smaller enterprise might be expected to prosper.

Provided that there is no radical change in our fiscal policy, England may now count upon a period of unprecedented prosperity. Development is proceeding and must proceed apace, and every day, under present conditions, sees England better fitted to meet outside competition. Provided that the English manufacturer is allowed to make legitimate use of his home markets, he will be able to put up a better fight for those in other parts of the world. For example, Longbridge turned its attention to the 20 horse-power car, the commercial vehicie, and the agricultural tractor. Later on, however, Longbridge busied itself with the manufacture of the small-powered car, and it was here that England scored. Despite the undoubted brilliance of our competitors and the unique opportunities that had been theirs, they overlooked the small car need.

In view of the peculiarly poverty-stricken condition of the people, particularly in Europe, economy should have been a watchword. Therefore, despite the wasted years, England had the start in this field, and the lead she obtained does not seem likely ever to be decreased. As soon as it was recognised as a practicable proposition, the Austin Seven was hailed with delight by those people who stood in sore need of mechanical transport but who could not afford to pay a big price therefor. As you already know, the Seven is manufactured under Licence in France, and is selling like hot cakes. Germany also obtained the licence to manufacture the 'baby' in that country, and there, too, it is enjoying a remarkable popularity. Fortunately, it was not only in Europe that the Seven found its market. It is also needed in outlandish parts of the world where the call is for a tough proposition that can live a long while on very little fodder."

He had this to say on the question of Buying British Products. " I would like to impress upon the people of this country that if they have the interests of the nation at heart and wish to see the solution of our unemployment problem, the dole a thing of the past, prosperity a condition shared by all, then they should see to it that it is a point of faith to purchase nothing but the truly British article wherever and whenever possible. It has been the aim of the Longbridge factory to justify certain additions to the slogan which we now hear so frequently: 'Buy British.' There is, of course, the addition 'Buy' Best,' which the wise have long taken for granted; but the other addition is 'Buy Cheapest,''and this is now an accomplished fact. If a motor car is British, best, and cheapest, what more can anyone ask ? "

My other little bit of advice, chiefly tendered to the younger generation is: Be courteous. I do not address this to the younger generation because I think they are any less courteous than were their fathers, but because they have to carry on the good work. They were born with a steering wheel between their hands, and it is up to them to see that throughout their lives they are able to make the very best use of it. If motorists will practise a perpetual courtesy then will the motor car establish itself still more firmly in popular favour, and primitive legislation, which still hampers development, will be swept away. Common sense' and courtesy are the qualities required to make motoring safe."

Sir Herbert the Benefactor

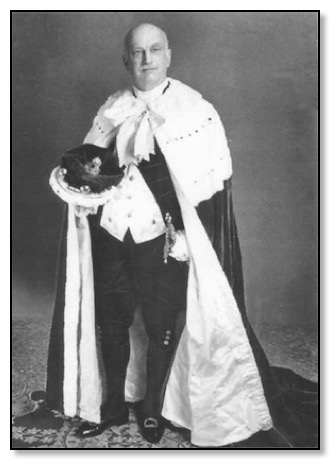

Lord Austin of Longbridge

Sir Herbert followed the example of that great motoring benefactor Lord Nuffield by presenting a small fortune to an educational establishment. He gave £250,000, which must have represented a high proportion of his own rather meagre personal wealth, to Lord Rutherford's Cavendish Laboratory at Cambridge University for scientific research into radio-activity. With the exception of Payton, whose wealth was derived from his many other interests, Austin directors did not build up vast fortunes. When Sir Francis Pepper died at the age of 75 in November, he left only a little over £80,000. Later Austin followed his major endowment with a gift of £7,000 to the Birmingham United Hospital for radium equipment and £1,000 to the National Hospital in London, and also paid off the debts owed by the Coach Harness Company, one of London's most historic City Guilds.

In 1934 William Morris had been honoured and taken the title Lord Nuffield after his £l million gift to Oxford University, which created Nuffield College. In June 1936 a delighted Sir Herbert, in his seventieth year, was made a baron in King Edward VIII's first and only birthday honours list. Unlike Morris, he decided to retain his name in his title - Lord Austin of Longbridge.

1912:- President of the Institute of British Carriage and Automobile Manufactures.

1927:- Knight of the British Empire and a Commander of the Order of Lepold II for his services in the war.

1918:- Member of the Institute of Mechanical Engineers.

1919-25:- Unionist Member of Parliament for the King's Norton Division of Birmingham.

-------------Member of the Government Labour Resettlement Committee.

1931:- President of the Institution of Automobile Engineers

1932:- President of the Institution of Production Engineers.

1932:- Chairman of the Birmingham General Hospital and later became Chairman of the new

---------Birmingham United Hospital.

1932:- Chairman of the Greater Birmingham Employment Committee.

1932-33:- President of the Institution of Production Engineers.

1933:- Appointed a Justice of the Peace for Birmingham.

1934:- President of the Society of Motor Manufactures and Traders Ltd

1934:- Master of the Worshipful Company of Coach makers and Coach Harness Makers.

1934:- Member of the Transport Advisory Council.

1934-35:- President of the Society of Motor Manufactures and Traders.

1936:- Created Baron, 'Austin of Longbridge'. Gave £250,00 to the university of Cambridge to forward the work ---------of Lord Rutherford

1937:- The university of Birmingham conferred upon him the honorary degree of Doctor of Law.

1937-40:- Chairman of the Shadow Aero-Engine Committee.

1937:- Member of the Livery of the Worshipful Company of Carmen.

1937:- Honorary Member of the Institute of British Foundrymen.

1937:- Honorary Degree of Doctor of Laws (LLD) conferred by Birmingham University.

1938:- Elected Honorary Life Member of the Institution of Mechanical Engineers.

1939:- President of the British Cast Iron Research Association.

1940:- President of the Birmingham United Hospital. Governor of the Royal Cancer Hospital London.

---------Life Member of the Court of Governors of the University of Birmingham.

---------President of the Motor trade Association.

Obituary

LORD AUSTIN

8-11-1866 to 23-11-1941

Lord Austin, a leading figure in the British motor-car industry and pioneer of the "baby" car, died yesterday at his home at Lickey Grange, near Bromsgrove, at the age of 74. As a boy he went to Australia to learn engineering and later returned to England to establish the motorcar manufacturing firm which bears his name. In May, 1940, Lord Austin retired from the chairmanship of the Shadow Aero, Engine Committee, which he had held for over four years. He had been largely responsible for coordinating the work of the shadow factories.

The Right Hon. Sir Herbert Austin, K.B.E., Baron Austin, of Longbridge in the City of Birmingham, in the Peerage of the United Kingdom, was born at Little Missenden, Buckinghamshire, on November 8, 1866, son of the late Mr. G. S. Austin, of Wentworth, Yorkshire. He was educated at Rotherham Grammar School and at Brampton College, and served his apprenticeship at Langlands Foundry, Melbourne. Soon his abilities were directed to the manufacturing and selling of sheep-shearing machines, work which necessitated long and laborious journeys to cutback sheep farms. Becoming an expert in the requirements of that type of plant, he returned to England in 1893 to control the production of the Wolseley Sheep Shearing Machine Company, and in 1900 he was made a director. He had been chairman of that concern since 1911.

The possibilities of the motor-vehicle began to engaged his attention soon after be came back to England, and in 1895 his first Wolseley car took to the road. In 1900, after several Wolseley cars had been produced, the Wolseley Tool and Motor Company, Limited, was formed with Austin as manager. After producing a number of successful designs he left the company to start manufacturing on his own account at Longbridge, near Birmingham. The venture, which grew so big, began in 1905 with some it £15,000 capital. In 1907, employing 400 hands, 147 Austin cars were made, and by 1914 the Austin Motor Company was producing 1,000 cars a year and employing 2,000 workers, The capital was increased by £250,'000 and when the last War broke out large-scale production of munitions was begun, as many as 22,000 operators being employed on shells, guns, aeroplanes, etc.

After the last War, Austin soon re-established his firm among the front rank of motor manufacturers, and with the successful introduction of the Austin Twenty in 1919, the Austin Seven and Austin Twelve in 1922, all cars of his design the future of the Austin concern was assured. From a production of 2,500 cars in 1922 the capacity of the Austin factory rapidly increased to over 60,000 a year, and new models such as the Austin Ten-Four, Twelve-Six, and Light Twelve-Four were put on the market. It is estimated that by 1937 the works, occupying 220 acres and employing more than 20,000 people had produced in all nearly 750,000 motor vehicles. The horse-power calculation for taxation purposes, of which Austin was a bitter critic, was the main factor which led him to produce his famous 7-horse power car. But in doing so he helped to bring in cheap" family motoring.

Lord Austin's activities were not confined to his business interests, for he had played an important part in the public life of Birmingham, and he sat as Unionist M.P. for the King's Norton division from 1919 to 1924. He was a generous supporter of charitable movements, and in addition to his many large gifts to hospitals he gave in 1936 £250,000 to the University of Cambridge for scientific research. In 1930 he was president of the Institution of Automobile Engineers; and in 1934 was president of the Society of Motor Manufacturers and Traders, and was master of the Company of Coachmakers and Coach Harness Makers. He was M.I.M.E., and Birmingham University conferred upon him the degree of LL.D. In 1917 he was created K.BE., and in 1936 was raised to the peerage.

He married in 1887 Helen, daughter of Mr. James Dron, and had a son and two daughters. The son was killed in action in 1915 while serving in France with the Royal Artillery. There is no heir to the peerage, which therefore becomes extinct.