Austin Healey 100

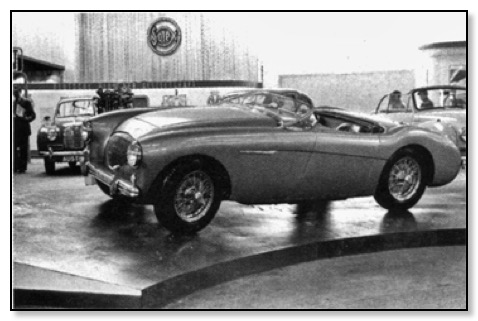

Donald Healey built cars at Warwick using one basic chassis design in 1946 Donald Healey showed at the 1952 Earls Court Show a new sports car using Austin A90 Atlantic running gear and called it the Healey 100. So impressed was the BMC's managing director Leonard Lord that a deal was struck, so next morning the model on the stand had a new badge which announced to the world that this was the new Austin Healey 100.

Healey 100

Healey would designs the cars and Longbridge would build and market them under the name of Austin-Healey. The actual body/chassis were made for BMC by Thompson of Wolverhampton.

It would take some time to get the sports car into production, at the earliest by the middle of 1953. As a production line would have to be set up at Jensen Motors of West Bromwich to produce the body, with a line set up at Longbridge for the final assemble.

So a decision was made that Donald Healey Motor Company would produce a small batch by hand that would be used mainly for publicity, such as Motor Shows around Europe and America, and also be loaned out for the press to try and the public to view. I'm sure that some would have been used by the team to test components etc.

Frankfurt Motor Show 1953

Donald Healeys factory was referred to by the workforce as 'The Works' and was actually a former aircraft hangar that was re-erected on three acres of reclaimed land made available by Warwick Council after WWII. Not the ideal place to build a stylish sports car. Offices were added later and also a brick workshop for Roger Menadue to house the experimental department. It was here that the first five cars were assembled. It was planned to produce the next batch of pre-production vehicles in the hanger, a total of fifty, under the watchful eye of Harry Bradish. Actually in the end only nineteen were made at Warwick all been left-hand drive versions.

The Sixth Austin Healey

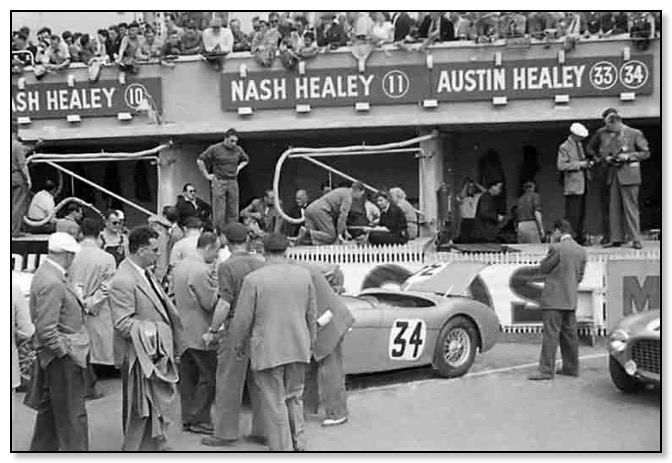

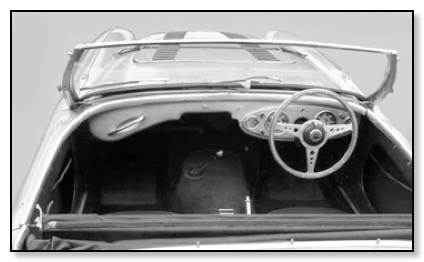

The Sixth Austin Healey (build No AHR60) was the second racing car to be built at Warwick. The car had a strengthened but lighter chassis with a special engine No IB 13676 supplied and built by Austin’s Experimental Department Longbridge. With a nitrided crankshaft, special camshaft, racing pistons and lightened flywheel. Various other modifications were carried out and for the Le Mans 24 hour race it was fitted with a cold air box and 1¾ SU carburettors, which helped the engine to produce 103bhp at 4,500rpm. A Borg and Beck competition clutch transmitted the power through to a Austin Taxi gearbox which also had a high ratio overdrive unit, which reduced the engine revs by a third, then finally to a high ratio axle.

It was registered in Birmingham on the 22nd April 1953 and given the number NOJ 392. The chassis number was SPL225B and body No JM 4079-6.

Donald Healey thought that British racing green was unlucky, so it was painted a metallic light green, with dark green leather for the seats. Then entered in the 1953 Mille Miglia with racing number 552, driven by Bert Hadley and Bertie Mercer. Sadly on the stage between Brescia and Ravenna they had to retire with a broken throttle linkage.

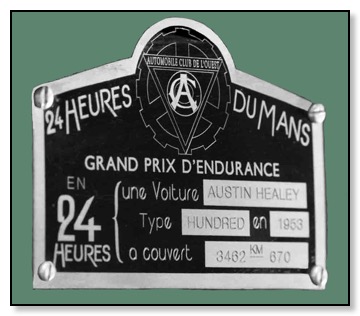

No 34 at Le Mans

Soon after the car was prepared for the Le Mans, but when driven back from the scrutineering session by Gordon Wilkins, he was involved in an accident. Because of the major damage, it was necessary to do a total rebuild to get the car ready for the practice session. On event day, bearing the race number 34 it completed 2,153 miles in the 24 hours, finishing in twelve overall and second in class.

This particular car is the only one that to this day is original in all respects.

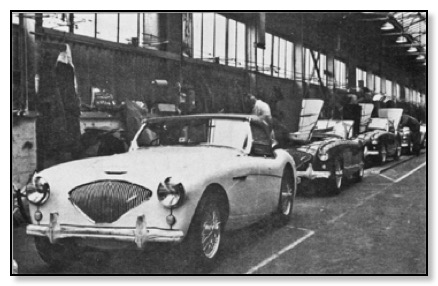

Longbridge Production

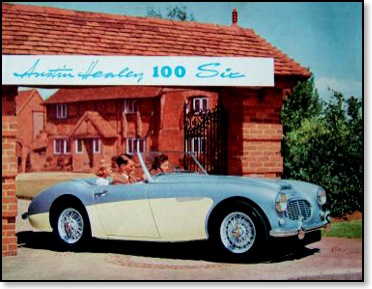

The first of the line built at Longbridge, with bodies supplied by Jensen was the 2.6 litre Austin-Healey 100 BN1 in 1953. Two years later came the BN2 version. Next on the scene was the BN4 and called the Austin-Healey 100 six which used the "C' series engine 6 cyl. 2,639 cc. this stayed in production at Longbridge till 1957.

Production was transferred to Abingdon in November 1957, at around the same time the engine was updated by means of a new cylinder head and manifold, this increased power from 102 to 117 bhp.

Later that year (1958) the BN6 arrived using the revised engine, one of the major changes was that the seating reverted back to the original design, making it a two-seater, not 2 + 2 as in the BN4. In 1959 it was change time again with the Austin-Healey 3000 Mk I Engine size went up to 2,912 cc and power output was now 124 bhp at 4,600 rpm with torque at 162 lbs/ft at 2,700 rpm. When the Mk II came out in 1962 it was called a Convertible as it had various changes with a more rounded larger windscreen and windup door windows. The soft top was now a proper foldaway type and seating layout was 2 + 2, although the room in the back was cramped for adults. Power output was again increased and although the overdrive unit was an optional extra, most were fitted with it as standard. It was in 1964 that the Mk III and final version was announced. The model was again given a more powerful engine along with a nice wooden veneer facia. Seating was improved and round the gear change was a central console with a storage box.

Model 100 BN1

Model 100/4 BN1/L

Model 100 BN1

Date when launched 1953 Discontinued in 1955

Total produced BN1 10,688

Engine

2,660 cc 90bhp at 4,000 rpm Max torque 150 lbs/ft at 2,000 rpm

Date when launched 1953 (100 BN1) 1955 (100 BN2)

Length 12ft 7ins Width 5ft 0ins Height (hood) 4ft 1ins

Wheelbase 7ft 6ins Track front 4ft 1ins rear 4ft2.8ins

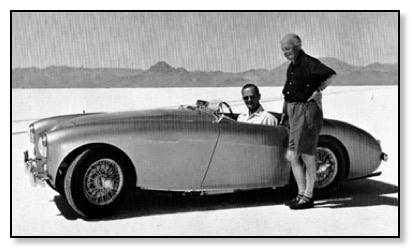

In 1953 the year that the Austin Healey 100 was announced at the Bonneville Salt Flats, Utah USA, a standard car broke all the American Stock Car Records from 1 to 5,000 km

Model 100 BN2

Date when launched 1955 Discontinued in 1956

Total produced BN2 3,924

Price ex Works BN2 (1956 Jan) £1,126

Engine

2,660 cc 90bhp at 4,000 rpm Max torque 150 lbs/ft at 2,000 rpm

Length 12ft 7ins Width 5ft 0ins Height (hood) 4ft 1ins

Wheelbase 7ft 6ins Track front 4ft 1ins rear 4ft2.8ins

Austin-Healey 100M (M standing for Modified)

Donald Healey converted 1,159 BN2 versions with a tuned engine.

Engine 2660cc comp.ratio 8.1 to 1. 110bhp at 4,500rpm Max torque 143 lbs/ft at 2,600rpm

Austin-Healey 100-six BN4

Date when launched 1956 discontinued in 1959

Total produced Longbridge 1956/7 6,045. Abingdon 1957/9 4,241

Price ex Works Feb 1957 £1,144

Engine

2,639 cc 102bhp at 4,600 rpm Max torque 142 lbs/ft at 2,400 rpm

Length 13ft 1.5ins Width 5ft 0.5ins Height (hood) 4ft 1ins

Wheelbase 7ft 8ins Track front 4ft 0.8ins rear 4ft 2ins

Austin-Healey 100-six BN6

Date when launched 1958 discontinued in 1959

Total produced Abingdon only 4,150

Engine

2,639 cc 117bhp at 4,600 rpm Max torque 142 lbs/ft at 2,400 rpm

Length 13ft 1.5ins Width 5ft 0.5ins Height (hood) 4ft 1ins

Wheelbase 7ft 8ins Track front 4ft 0.8ins rear 4ft 2ins

Austin-Healey 3000 MkI

Date when launched 1959 discontinued in 1961

Total produced Abingdon 2,825 BN7(2-seaters) 10,825 BT7(2+2 seater)

Engine

2,912 cc 124bhp at 4,600 rpm Max torque 162 lbs/ft at 2,400 rpm

Length 13ft 1.5ins Width 5ft 0.5ins Height (hood) 4ft 1ins

Wheelbase 7ft 8ins Track front 4ft 0.8ins rear 4ft 2ins

Price ex Works

(Oct 1959) £1,168 (2 seater) £1,175 (2+2 seater)

Austin-Healey 3000 MkII

Date when launched 1961 discontinued in 1962

Total produced Abingdon 355 BN7(2-seaters) 5,095 BT7(2+2 seater)

Engine

2,912 cc 132bhp at 4,750 rpm Max torque 167 lbs/ft at 3,000 rpm

Length 13ft 1.5ins Width 5ft 0.5ins Height (hood) 4ft 1ins

Wheelbase 7ft 8ins Track front 4ft 0.8ins rear 4ft 2ins

___________________

Austin-Healey 3000 MKIII

Date when launched 1964 discontinued in early1968

Total produced Abingdon 17,712

Price ex Works

Oct 1965 £915

Engine

2,912 cc 148bhp at 5,250 rpm Max torque 165 lbs/ft at 3,500 rpm

Length 13ft 1.5ins Width 5ft 0.5ins Height (hood) 4ft 1ins

Wheelbase 7ft 8ins Track front 4ft 0.8ins rear 4ft 2ins

Austin Healey 200 MPH

In 1953 the company wished to gain publicity for the Austin Healey specially in the USA. One of the best ways to get press coverage is to break some speed records, and what better place than the Bonneville salts flats in the state of Utah?

In that year Donald Healey Motor Company had built a special version of the Austin-Healey 100 sports car with the aim of setting both high-speed as well as endurance records. This Endurance car, which looked not too dissimilar to a standard Austin-Healey 100 was driven by Donald Healey himself, George Eyston, Carroll Shelby, Mort Goodall, and Roy Jackson Moore.

Donald Healey had thought of building a special streamlined record car, but time was against him to start from scratch. So a decision was taken to use a production car as the basis for the new car. It would be necessary to improve the shape of the body to improve its aerodynamic properties. So a scale model was made of the proposed streamline shape, and as a result of tests carried out by the Armstrong Whitworth Aircraft Ltd. in their wind-tunnel. It was from these results carried out that Healey would need a new front and rear end, with bubble-type Perspex cover for the driver. Austin's experimental sheet metal department made a revised body that could be fitted to the standard chassis.

Streamliner on test in Austin's Wind Tunnel

From results taken by the Austin technicians on the Streamliner in the wind tunnel, and then comparing this data with results from other models, they calculated the Streamline potential maximum speed would be 200mph.

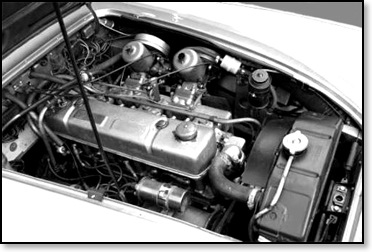

Now work started on increasing the output of the 100S competition engine, which in standard tune delivered 130 bhp at 4,700 rpm. This engine already had nitrided crankshaft running in trimetal bearings and special cylinder head with enlarged valves and special porting. To eliminate the possible problems using a head gasket, it was decided to lap-in the head to the block.

Dr. J. H. Weaving, head of BMC. Gas Turbine Research, was responsible for the preparation and tuning of this engine. He decided that the best way to get the power needed, would be to supercharge the engine using a standard Shorrock Type C250B. This was the largest one available, and connected to the front of the crankshaft via a Layrub couplings. The maximum boost available was about 8lbs/sq with this setup the engine was now producing 224 bhp at 4,500 rpm

With the extra power generated it was necessary to increase the capacity of the cooling system. Coventry Radiator and Presswork co., Ltd. produced a special radiator core that was installed in the streamlined nose. Tecalment company were involved in suppling a combined oil cooler and filter for the engine, along with a large diameter tube which fed fresh air into the cockpit.

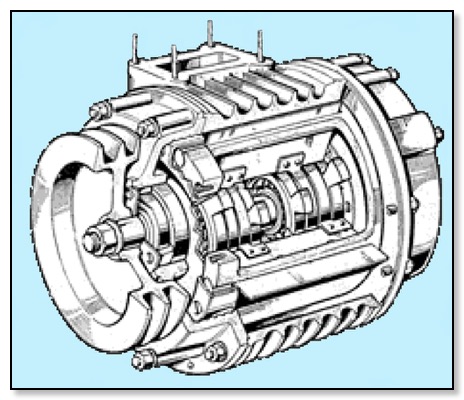

Shorrock Supercharger vane type

Attention now moved to improve the transmission by installing a five-speed gearbox with built-in overdrive which gave a top gear ratio of 2.2 to 1. Dunlop provided disc brakes and 16" disc wheels, which were standard on the 100S, but with a streamline body shape they had to work a lot harder to bring the car to rest. In fact on one occasion the engine was cut at 180 mph and it coasted for six miles before coming to rest.

Donald Healey had great experience of competition work and was able to recommend various safety precautions. This included a complete Graviner fire extinguisher system, which is mounted for both the engine compartment and the fuel compartment in the tail that holds the 25 gallon tank. The system was fitted with an impact switch which brought it into operation automatically should the car sustain an impact above a set figure. The system could also be operated by the driver, with a red button that replaced the normal horn button in the centre of the steering wheel. Instead of the normal steering wheel the Austin Healey works produced a special rectangular shape for Donald Healey as a normal wheel interfered considerably with his vision from the cockpit.

Other safety devices included a crash arch behind the driver, two levers, one on each side of the cockpit, to enable the driver to jettison the blister cockpit cover, and a special switch in the engine lubrication system which at once would switch off the fuel supply if the oil pressure dropped below a certain figure, to prevent a fire following an engine blow-up.

It was now time to do some testing by Geoffrey Healey in the UK at a local airfield, where speeds of 130 mph were attained. After some small modifications to the engine and suspension, the car was ready to be shipped to the Salt Flats.

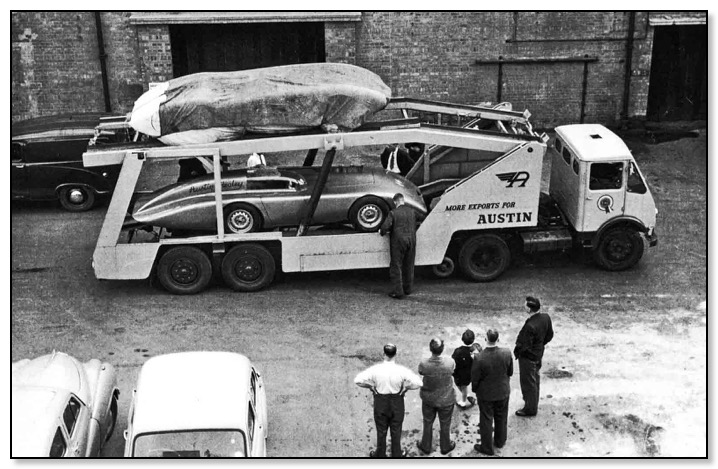

Picture shows the Endurance car covered up on the top deck, and the Streamline on the bottom.

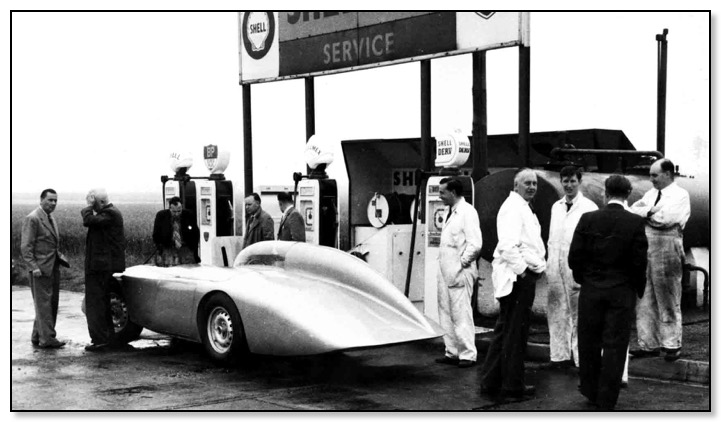

This is outside East Research by Groveley Lane

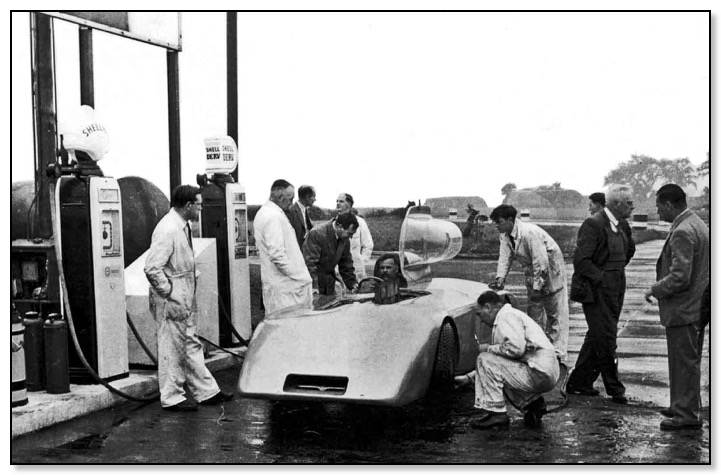

Filling up with fuel etc ready for the first run.

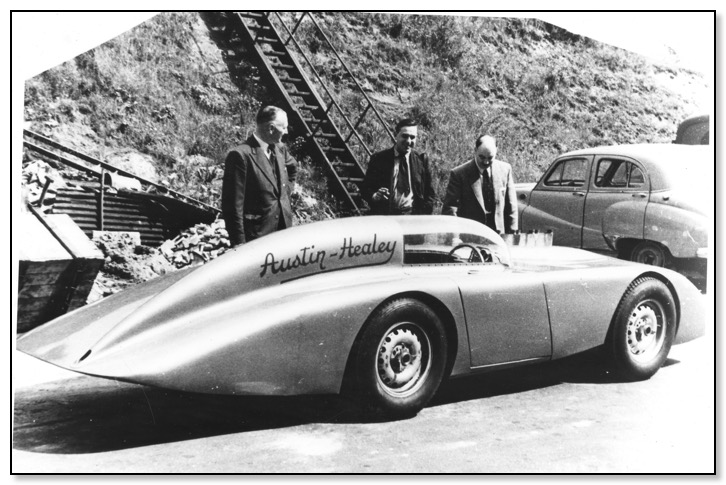

This shows the flowing curves of the rear end.

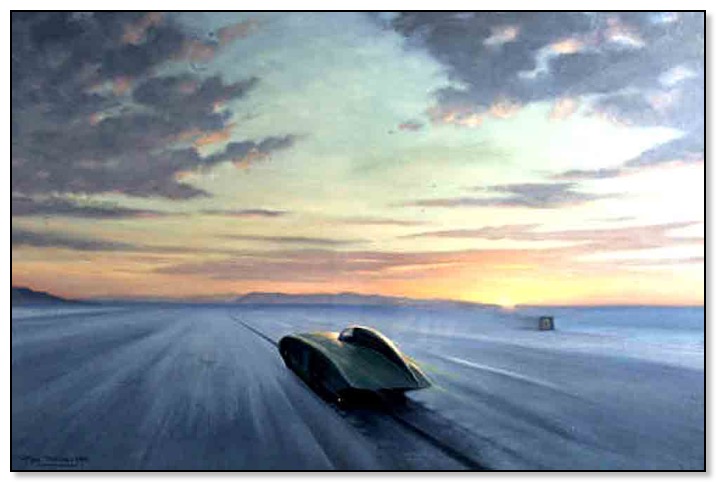

On arriving at the Bonneville Salts Flats they found out that part of the normal track was breaking up. So it was necessary to move the measured mile closer to one end of the timing stretch, thereby reducing the length of the run-in in this direction. Donald Healey drove the car on the straight-away runs and raised the International Class D for 5 kilometres to 182.2 mph and for 10 miles to 181 mph The car was timed over the kilometre at 192.6mph, thereby breaking an American National record. various other runs were completed and one such run broke the magic 200 mph barrier.

Then Carrol Shelby, the Texan driver who competed in many European events during the 1954 season, took over and attacked the International Class D record for the hour, which was duly obtained at a speed of 156.7m.p.h. For this run, a 10-mile circle was used, a course which seemed almost one long straight when seen from behind the wheel of a normal saloon but which seemed more like a rather difficult fast bend from the Streamliner's cockpit. The car proved very stable, which was indeed fortunate, for conditions were by no means ideal, gusts of up to 30 mph. sweeping across the Salt Flats. Moreover, owing to the complete absence of trees or any other vegetation, the driver received no advance warning of a gust before it struck the car. This is where the tail fin proved to be of real value in such circumstances.

Austin-Healey at speed on the 22 August 1954 on the Bonneville salts USA this modified Austin Healey “100” was timed by the American Automobile association officials over a measured mile at a mean speed of 192.6 MPH. At the same time a number of Class D international records were broken. It is on such occasions that research and development are put to the severest test which motoring have so far devised – record-breaking.