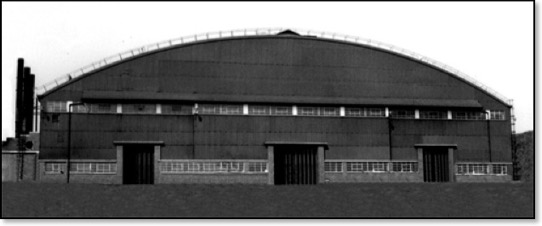

Flight Shed

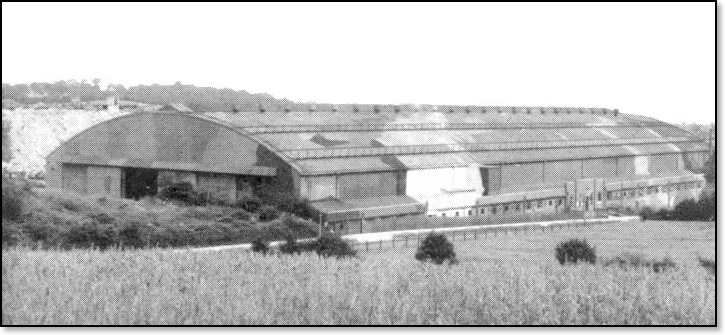

The Flight Shed, erected in 1936, was the first building constructed at Longbridge

under the WWII Shadow Factory Scheme.

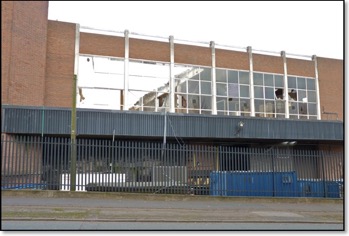

Showing the roof late 1990s

It measured 180ft x 500ft with a height of 25ft. The impressive steel roof was based on a German design called Lamella Construction, developed in the 1920s. In 1929 rights were acquired by Horseley Engineering of Staffordshire. This Tipton company made the tooling and pressings. The steel sections had ends bent to a precise angle; when four were bolted together they formed a diamond shape. Continuing to join all the sections together produced a lattice arch, which was self supporting. Finally, the roof arch was clad in corrugated metal and had three rows of roof lights.

At both ends of the building were large sets of doors; those on the Groveley Lane end allowed both the Fairy Battle and Hurricane aircraft, assembled in East Works, to be towed into the Flight Shed to be fitted out with engines, etc. The completed aircraft finally emerged from the other gable end doors, to be pushed onto a cable operated lift that took them up to Austin’s own airfield. After a successful test flight the aircraft were flown to various allotted airfields.

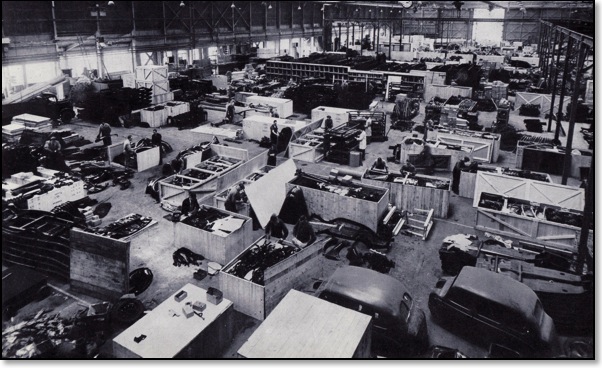

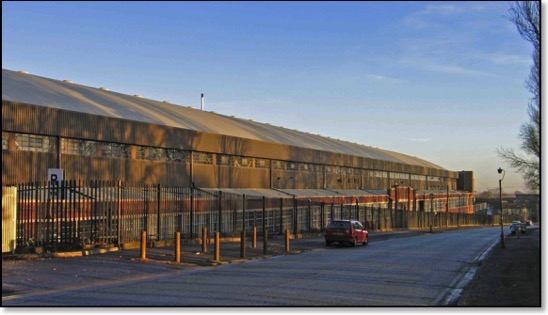

CKD Packing Department

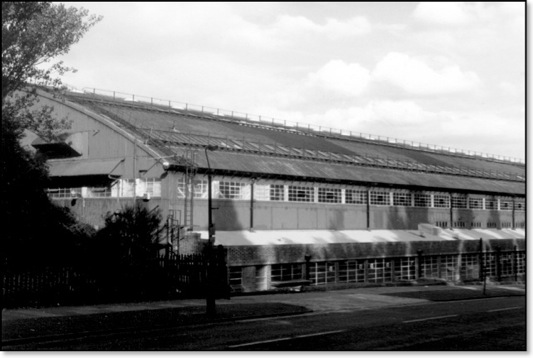

After the war the building became a packing department for CKD exports. Later its role changed to the Works Service Department. In the late 1960s the Service Department closed down. Around 1970 a brick extension was built, with the enlarged building now producing the Morris Marina gearbox. Its role changed yet again in the late 80s when Engineering took over the Flight Shed, and this continued until the collapse of MG Rover in April 2005.

View from Lowhill Lane 1950-60s

Flight Shed as the works Service Department 1950-60s

One of the main problems with this design of building was the high cost to heat. Also the roof itself was only designed to support it own weight. So if there was a large snow build up, it was necessary to send the maintenance crew onto the roof to remove the snow.

In April 1978 British Leyland UK Ltd. contacted the Horseley Company who had made the "Lamella Arch" system for the roof in 1936. The company was now called Carter Horseley Engineers and were now part of NEI John Thompson Ltd Tipton. BL was looking to replace the outer fabric of the roof, and wondered if it would be safe to install a sprinkler system and suspended ceiling at the same time.

Their findings were that the proposal would imposing an additional loading on the roof of 7-8lbs. per square foot, and should not, in their opinion, be pursued. Also snow loading on this building, such as those recently experienced in Devon, could result in failure as improving the thermal insulation of the building, the snow load would dissipate a lot slower.

This picture shows the new roof which was installed in 1989.

With the state of the roof deteriorated over the years. Director, Roland Bertodo for Powertrain Engineering facilities on making a visit to the Flight Shed, remarked that the roof looked a bit ropy and wouldn’t it be a good idea to fix it, to protect the investment. Funding from the capital investment budget of Product Engineering for £1m was agreed.

Demolition started in September 2011

The roof is brought down 14 Dec 2011