Austin Racers

Barry Lovelock

Why were these cars given the nickname “Grasshopper” which has stayed with it over the years. It is believed that Bill Sewell, Lord Austin's personal aide, was the author of the name, inspired no doubt by the well known Austin Seven reaction to the initial transmission of power from engine to axle!

It was in the Easter of 1935 that the company announced it would be entering the MCC Lands End Trial, with a team of three “Special Austin Sevens”. At the time they were described as Austin Seven “Speedy” sports car with a body similar to the Singer of the day. competing in the hands of Messrs. Orford, Milton and Richardson. Mechanically the cars differed very little from the Speedy. They had two-bearing pressure lubricated engines and as the competition dept. extracted more and more power out of them they experienced a great deal of crankshaft trouble. Eventually Laystall Engineering made a special 1 1/2inch cranks which helped, but was not a complete cure. The inlet manifold and carburretor was "Speedy" as was the exhaust arrangement which ran under the chassis to the rear of the car. The petrol tank which was immediately behind the seats and held 6 gallons incorporating a quick action filler cap, to the rear of this was two spare wheels. One of the main distinguishing features was the radiator cowling which was very modern and clean looking.

Barry Lovelock

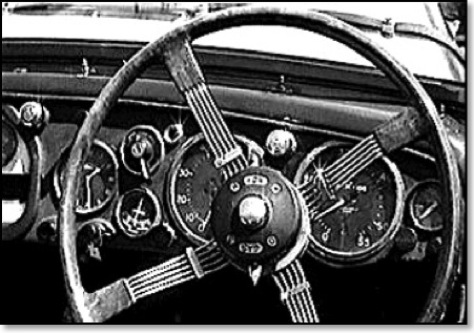

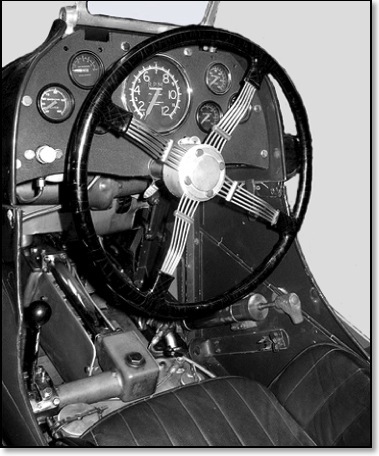

The dash consisted of a match pair of 5 inch diameter instruments for the speedo which shown a max speed of 120 MPH and the tachometer that went up to 8,000 RPM. Small instruments included an ammeter, oil pressure gauge, water temperature gauge and an ordinary time clock. Gear changing was by means of a nice remote arrangement. Visibility was through a fold flat rather shallow windscreen.

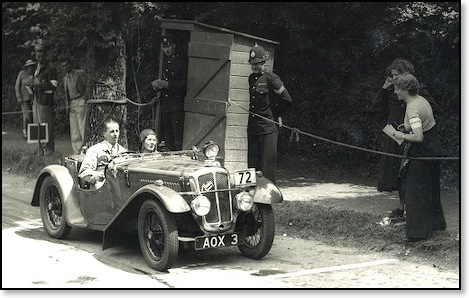

It was quite normal in those days to register racing variants of models, so the first three cars were registered AOV 343 (25.3.35), AOX 3 and AOX 4 (4.4.35). Below is AOX 3 competing in a reliability trial doing a stop and restart in around 1935-6. The driver is a Mr W.J.Millton who was a Dental Surgeon in Welbeck Street in the West End of London. It appears that he used to use Douglas motor bikes for trials, but became a friend of Herbert Austin who persuaded him that he should have a Grasshopper.

Soon after a further four cars were built so as to compete in the Le Mans 24 Hour Race. The bodywork of the Le Mans cars was very similar to the original three, but cycle type wings were fitted front and rear. Quick action fillers were used on the radiators. They did, however, have the benefit of a Murray Jamieson designed aluminium cylinder head with a long water take off running almost the full length of the head to aid cooling and fitted with 14 mm. plugs. These cars were all registered on 24th May, 1935, with the registration numbers BOA 57 58 59 60. The Le Mans competition numbers allocated to the team were 59, 60, 61 and 62. which must have caused some confusion because of the registration numbers. In the Race the team had mixed fortunes, as two retired and two finished in 27th and 28th places out of 28 finishers.

1937 Trials

On returning back to Longbridge they were fitted out to complete in "Reliability Trials", these events were similar to the current "Classic Trials" and many manufactures took part as a good way of publicising their products. The cars performed well but really needed more power, so for the 1936 Colmore Trial one of the cars was fitted with a "Blower" and the modification proved to be a great success. All the remaining cars were then modified using a Centric Type 125 supercharger. The blower which was driven by a V-belt from the fan pulley, sat on the forward end of a very neat aluminium manifold which replaced the "Speedy" manifold previously used. On the rear of this manifold was a blow-off valve which was preset to 6 lbs./sq. in., but later increased to nine. The blown two-bearing engine would rev at 7,000 r.p.m. although most torque was developed low down. The cars had a top speed of around 80 m.p.h., achieving 60 in third. The SU (1 3/8ins) carburettor used in downdraught form with the dashpot lying horizontal was mounted directly on the blower port, it was the fitting of this SU which caused the rather inelegant bulges that appeared on the bonnets of the Grasshoppers when in Trials trim. Supercharging was never used when the cars were raced.

The Company decided to build a further four cars for the 1936 Le Mans. The four cars were registered on 12th May 1936 as COA 118 – 119 – 120 – 121 and were soon down at Brooklands testing. Very few alterations to the bodywork were made as compared with the 1935 Le Mans cars, although to save weight the doors were omitted, the 10-gallon fuel tank was used and once again cycle type wings. The engine was now in three-bearing form and had a crankshaft with fully circular webs. The oil feed to the centre main bearing was via a copper pipe delivery direct from the main oil gallery which later turned out to be a major problem. Shell bearings were used on the big-ends and the con-rods were fully machined all over. The cylinder block had larger water passages around the valves and ports, the connecting water passages between block and head were elongated slots, and the internal sweep of the inlet ports was different from other Austin Sevens. The block was attached to the crankcase by 10 x 3/8th studs. The block was also "taller" than standard in order to accommodate unusually long valves. Very powerful double valve springs were used to partner a fairly ferocious cam profile. Tappet blocks were short and adjustment of clearance was effected by grinding tappet "buttons" to the correct thickness. "Speedy" manifolds were used as the engine was run without a supercharger. The wheel and tyre size remained at 19 inch x 3.50.

Because of industrial unrest in France in 1936 the 24-hour race was cancelled, so the cars were mothballed to await the 1937 race. In 1937 they decided to only enter three cars. Again little modification was carried out, but one of the changes was going down from 19in wheels to 17in. but with larger section 4.00 tyres, which only reduced the rolling radius slightly, so that the gearbox ratios could remain the same but they greatly improved the road holding. Disaster struck again as all three retired when the copper oil pipe supplying oil to the centre main bearing fractured.

After Le Mans the engines were rebuilt and three cars were entered for the 12-hour sports car race at Donnington. Reliability was restored and they finished 2nd Dodson/Hadley with Goodacre/Buckley in 3rd and 5th place taken by Kay Petre/Stevenson in their class. The distance covered was some 1,800 miles. Soon after with moral high one car was entered for the Paris-Nice Rally in September, 1937, driven by Kay Petre and Mme Itier.

If you know the position it finished at etc, please let me know.

It is amazing that of the twelve Grasshopper made including the above, that seven are still around, although not necessary in original form as shown below.

AOV 343: - AOX 3: - BOA 59: - COA 118: - 119 - 121. UI 3345:

Barry Lovelock

75th Anniversary of the 7 in 1997 at Gaydon

Information supplied by Barry Lovelock

______________________

Austin Seven Racers

Captain Arthur Waite, who had been a successful racing driver was given the job of managing the works racing team, and in 1925 he wanted to prove that a Austin Seven could do 100mph. The easiest way of increasing the power of an engine is to fit a supercharger. This was tried, and the power output increased from the normal 25 to 43bhp. In April 1925 he covered a flying start mile at 92.44mph. The Austin company offered Malcolm Campbell a car, and he recorded a speed of 94.03 mph.

The first vehicle to achieve 100mph (750cc) was an MG driven by George Eyston in France at Motlhery; he also broke all the records held by Austin. This was the trigger to spur Waite to decide to build a special single seater.

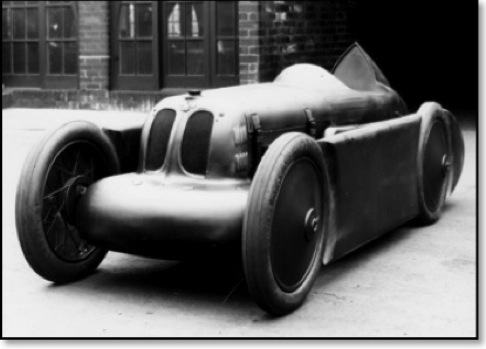

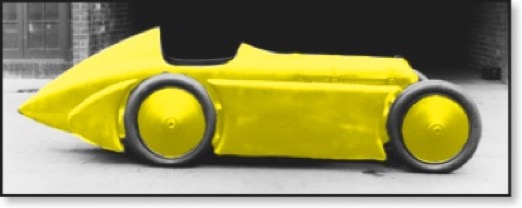

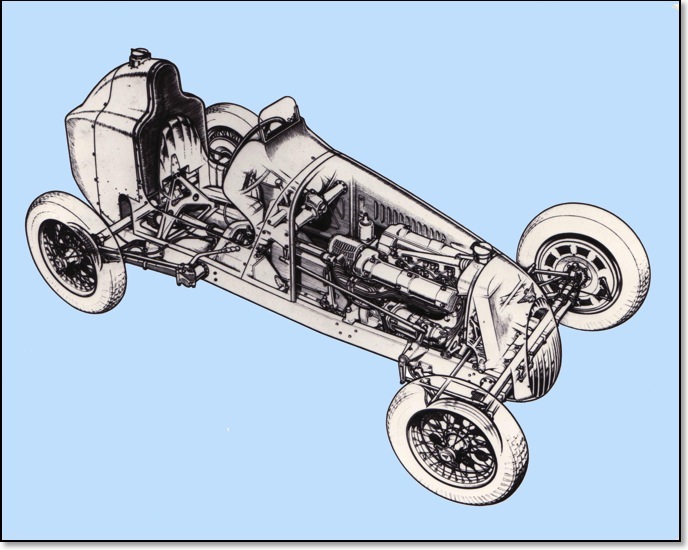

You will see from the picture below that it was very streamlined. In fact, various scale models were made and tested in Vickers Wind Tunnel. The end result was a design that had similar appearance to the famous Bluebird record-breaking car of the day. The driver was seated very low down and slightly to one side, so that the drive from the engine, which was offset the other way, could pass to the rear axle. The engine used was basically an Ulster unit but with a special camshaft and an Austin built Rootes type two-lobe supercharger that produced 56bhp @ 6,000rpm.

The cockpit had been customised for Davis to drive at the 1931 Easter Brooklands meeting, but a few weeks before the event he broke his leg, it was decided that Gunnar Poppe would be the first driver to take it out. The car was actually painted a vivid yellow, so the crowd nicknamed it "Flying Canary". In fact it did not do well, only completing one lap.

Artist Impression

Later in 1931, having carried out various modifications, the car returned to Brooklands, and driven by Leo Cushman, soon recorded 99.0mph. It was decided to strip the engine down, and it was found to have a cracked valve seat. The engine was rebuilt with a new block, and after a few laps covered the two-way kilometre at 102.28mph and the mile at 100.67mph, which bettered Eyston's MG records. Therefore at last the Austin was the first 750cc car to do 100mph in England. The car was later taken to Montlhery. This time the radiator was moved forward of the engine in a separate cowling, this was done to improve the cooling, the driver this time was Mrs Stewart who achieved the following records.

5 kilometre at 109.1mph, ........5 miles at 109.6mph,

10 kilometre at 109.5mph, ......10 miles at 109.06mph

50 kilometre at 98.08,.............50 miles at 98.43mph

_________

In 1932 Stan Yeal who was testing the works Ulster Seven at Brooklands, observed that a white Ulster Seven was recording better times than him, so he approached the driver to find out his secret. The driver T Murray Jamieson, was actually testing out his own design of supercharger, which had been built by Amherst Villiers Superchargers Ltd, who had been producing their own supercharges since the early 1920s.

On returning to Longbridge Stan told Captain Waite, who was in-charge of the racing department, that he thought Jamieson would be worth employing. Negotiations between Waite and Villiers took place and the Austin Motor Company agreed to buy from Villiers the white Ulster complete with all spares, special tools and drawings of the upercharger. Jamieson was then employed as a designer at Longbridge and given the task of building the fastest 750 cc Racer.

Murray Jamieson’s first Austin venture early in 1935 was a super streamlined body on the Seven with a side-valve supercharged unit of his own design enabling the engine to produce 70 bhp. It successfully attacked the records previously held by MG.

_________

Austin Seven OHV Twin Cam Engine

Copyright Autocar John Ferguson

In 1935 it was decided that to be competitive it would be necessary to design a completely new engine along with a new chassis/body. Murray Jamieson headed the design team along with W V Appleby and Tom Brown, who would start on the drawings and development of this radical 750 cc engine.

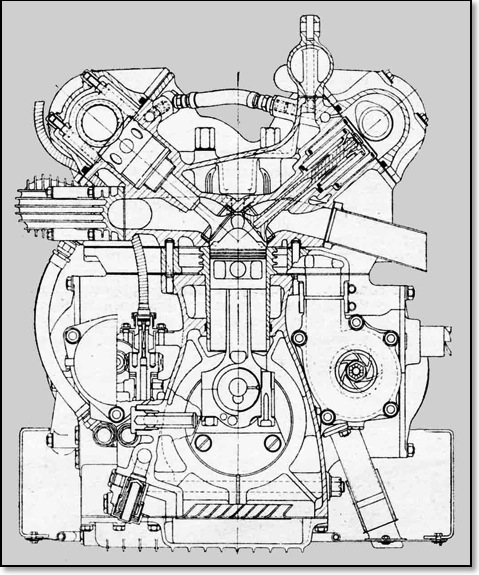

Cross-Section of the 750cc Twin-Cam Engine

Jamieson's plan was to produce a 750cc engine that would give 120bhp at 10,000rpm. Most experts at the time said that with this specification it would smash itself to pieces. Because of the high revs planned, it was necessary to keep the piston speed down, so the engine would need a a short stroke of 65.09mm. So with a large bore of 60.32mm it was possible to have a large hemispherical combustion chamber along with large valves. Owing to the high cylinder pressures being produced it was decided that they would do away with a cylinder head gasket, as this item often gave trouble. The cylinder block was completely open with the four wet liners rising approx 0.125 inch above the top edge of the block. Four studs placed evenly round each bore held the cylinder head against the liners. With a perfect metal-to-metal gas joint between the liners and cylinder head, this unusual design actually gave no trouble. Between the block and the head was a casting that allowed the cooling water to pass from the block to the head, with a rubber joint washer on each face to seal the water passages.

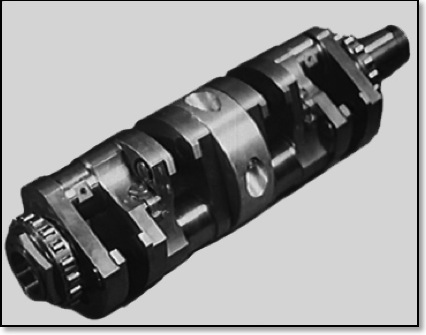

A centrifugal water pump gave 50 gallons/min which was driven at half engine speed. Tests showed that the exhaust valves and ports could be 30% less than the inlet. The camshafts cams were very wide and were plated (fescolized) to reduce wear. The steel connecting rods had plain big end bearings. Cast aluminium pistons were used of the slipper type. The crankshaft was machined from a solid steel billet, counter balanced and with a roller bearing front and rear, and a plain bearing at the centre.

Crankshaft

A single SU carburettor connected to a Murray Jamieson Rootes type supercharger was driven by a rear spur gear train arranged so that the speed of the supercharger could be varied according to the type of event entered. The maximum speed was 1.5 times engine speed or 15,000 rpm, with a maximum boost of 22lbs/sq inch. The gear train also drove the two overhead camshafts, with each cam running in three bearings 2 inches wide.

Two 14 mm spark plugs per cylinder were connected to a vertical type Scintilla magneto. The drive to the magneto also connected with the oil pump and tachometer. Lubrication was by means of the dry sump system, with the triple layer sump oil being fed to the centre main bearings and big end at high pressure, and under low pressure to camshaft and supercharger. Oil (Castrol R) was stored in two one gallon tanks positioned on each side of the propeller shaft, with an oil cooler positioned behind the radiator.

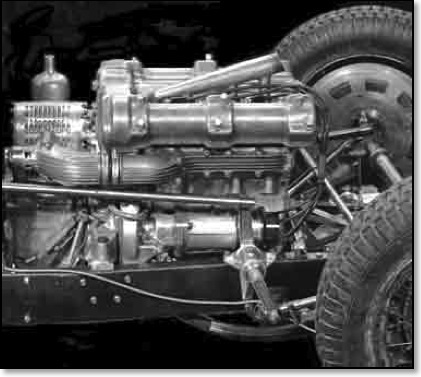

As there was no flywheel, power was transmitted straight through via a single dry plate clutch. A four speed crash gearbox was first fitted, but later on a synchromesh version was developed, with the gate change on the left of the driver. The gearbox was then connected to a fully floating back axle with double reduction bevel and spur drive. This arrangement gives a particularly low transmission drive-line, so giving the racer a low centre of gravity.

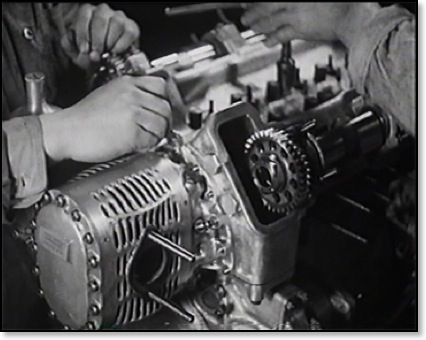

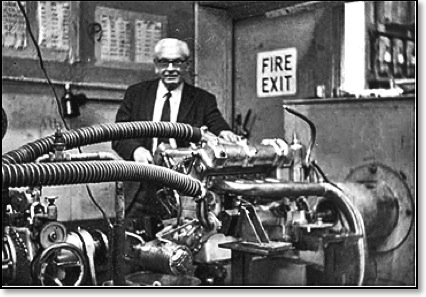

Raleign Appleby with the Twin Cam on test

The first engine was built but could not be completed as the supercharger had not been delivered. It was decided to test run the engine without the supercharger, by fitting a different inlet manifold, but on test it only produced a disappointing 22bhp. Soon after, the supercharger arrived, and it was a different story, in that it was now producing 90bhp at 8,000rpm. After carrying out fine tuning, along with ongoing minor changes and trying out various compression ratios, it was found that 6.5:1 produced the best result. At the end of the development period the engine was now producing a steady 110bhp with short bursts up to 116bhp at over 8,000rpm.

The engine produced 90 bhp @ 7,600 rpm on long distance fuel, with a fuel consumption of 7.5 mpg, 116 bhp @ 9,000 rpm on sprint fuel (methanol added). Fuel consumption was 3.5 mpg.

The hand pump on the right was to pressurise the fuel tank, which needed to be pumped several times in a race, as no mechanical pump was fitted. The fuel tank behind the driver held 25 gallons.

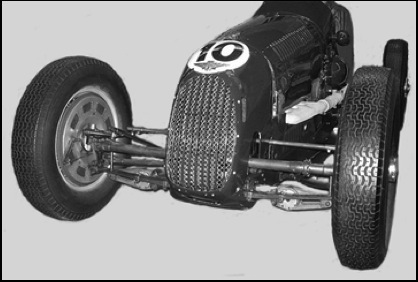

The chassis frame had tubular cross members extended to carry the front shock absorbers and rear spring brackets. The special tubular front axle is torsionally non-rigid. The braking torque is taken by struts and ties anchored to the stub axle and frame, and the stub axles, although held in alignment by the axle, can adjust their relative positions axially as required by road or braking inequalities. This construction, unlike the orthodox Austin Seven system of springing (a transverse front spring and quarter-elliptic rear spring) made for good stability. It was fitted with 12.5 dia drums at front which were heavily ridded to aid cooling, and 10 inch drums at the rear. Tyres were Dunlop 5.25 x 16. Wheelbase 6ft 10ins Track 3ft 11ins Length only 10 ft 1ins The running weight was 9cwt 84lbs.

The cars first trial run was made in October 1935 at Donnington, which proved successful, with the official report stating, after testing that it went like the 'proverbial scalded cat'. More testing took place, and two more cars were then built, as they needed three cars to be ready to compete in a full programme of events for the 1936 season.

On 18th March 1936 at the Grand Hotel, Birmingham Lord Austin announced to the press that the new racer would develop 1 bhp for every 2 ¼ lb weight. He said he believed in spending money to improve the breed and sincerely hoped that the new OHC Austins would win many races, and thereby add much to Britain’s motoring prestige. There was a complete car on show, along with a chassis. It went on to capture the 5 and 10 mile and 10 kilometre from the MG at the following speeds: 119.38 – 119.39 and 119.19 mph. but Jamieson was disappointed that it did not quite make it to 120 mph.

Various modifications were carried out mainly to increase the power and reliability. One problem was fuel surge when taking right hand bends, causing a lean mixture. This was remedied when the SU representative suggested that the carburettor be fitted with two float chambers on either side, thus even out the fuel when cornering. This cured the problem, and in autumn 1936 all the cars were modified.

By the end of the 1937 season modified bonnet styling enclosed the radiator filler cap. The cars having had a successful season, the Austin OHC 750 cc Racer was now recognised as the finest in the world in its class. In 1938 various small modifications were carried out, the bonnet now having louvres now put in the crown and sides.

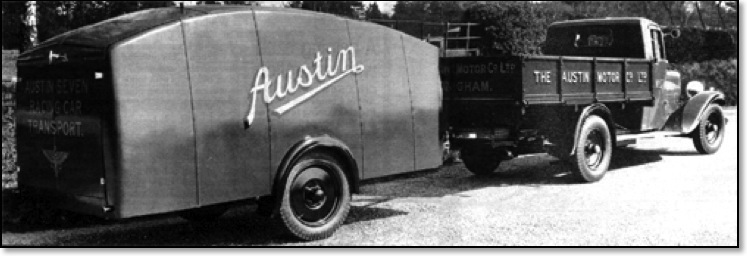

The 750 Racer was transported in this trailer.